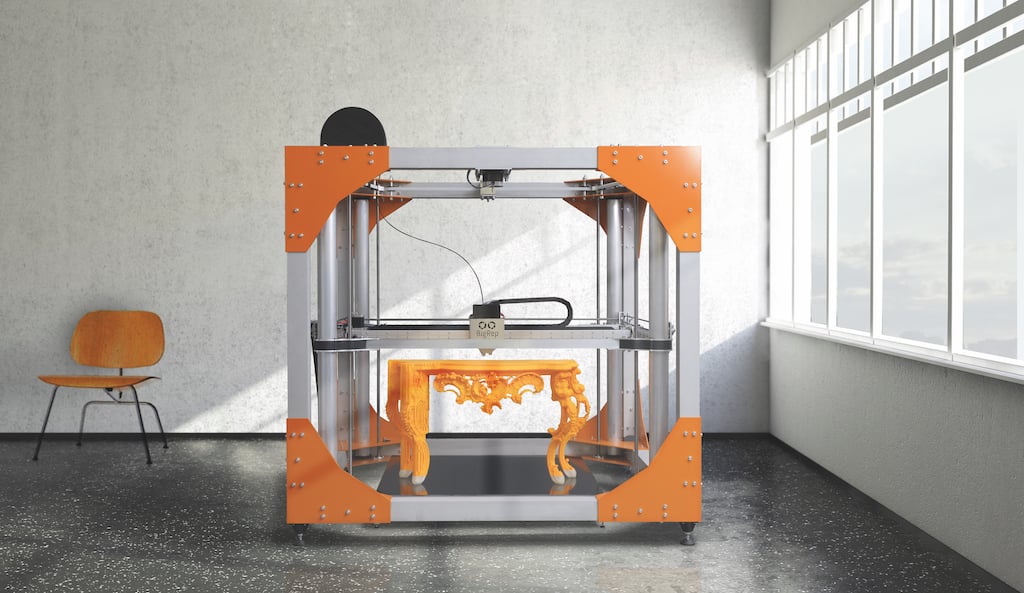

We spoke with BigRep CEO René Gurka, whose company produces the gigantic BigRep ONE 3D printer, to find out how the company has changed and where it’s headed.

Fabbaloo: BigRep was just a small startup only a few years ago. Now things are a bit different. What happened?

René Gurka: We definitely started at the right time with the right idea. We were THE pioneer for large scale affordable printing at the beginning of 2014 and still are the segment leader in this market today.

Since our launch, we have gone a long way. Six weeks after building the first prototype in January 2014, we took the prototype to the 3D Print Show in New York and people went crazy: We got hundreds of inquiries both from resellers as well as media from all over the world after the show which helped a lot to make BigRep known in the 3D printing community.

But of course, this alone does not make a company successful. After getting all the attention, we had to start building the company. We recruited great people and great investors – all with a background and knowledge in hardware start ups, so we could grow from 3 to 50 people in only 15 months.

I have to say that at BigRep, the execution of creating a prosperous company went very well and I am convinced that the right execution is sometimes more important than the idea itself. Making the right decision is definitely not easy and it will always take a few bad ones to find the right path for you. My tip for founders is: Get help before making too many mistakes in the early days.

Fabbaloo: Our understanding from the early days was that one of the original target markets was artists wishing to print large works at lower cost. Is this still the case, or have your markets shifted?

René Gurka: Yes, artists and designers were initially our main target group. My two co-founders who brought the idea of the BigRep to me and my partners, have a background in the arts. They worked as artists and experimented with the first prototype of the BigRep ONE. We have been, however, shifting markets: In my opinion, large scale 3D printing is maturing and we get more and more approached by industrial customers. That’s why we are now focusing more on industrial 3D printing.

Nevertheless, we still work closely with a lot of artists and designers focusing on 3D printing like Thorsten Franck, Oliver Vogt or Daniel Büning and Jörg Petri from the design studio NOWlab. My biggest surprise last year was to see a picture of a large bronze sculpture standing in the desert at Burning Man – its mold was printed by our customer Artworks Foundry in Berkley.

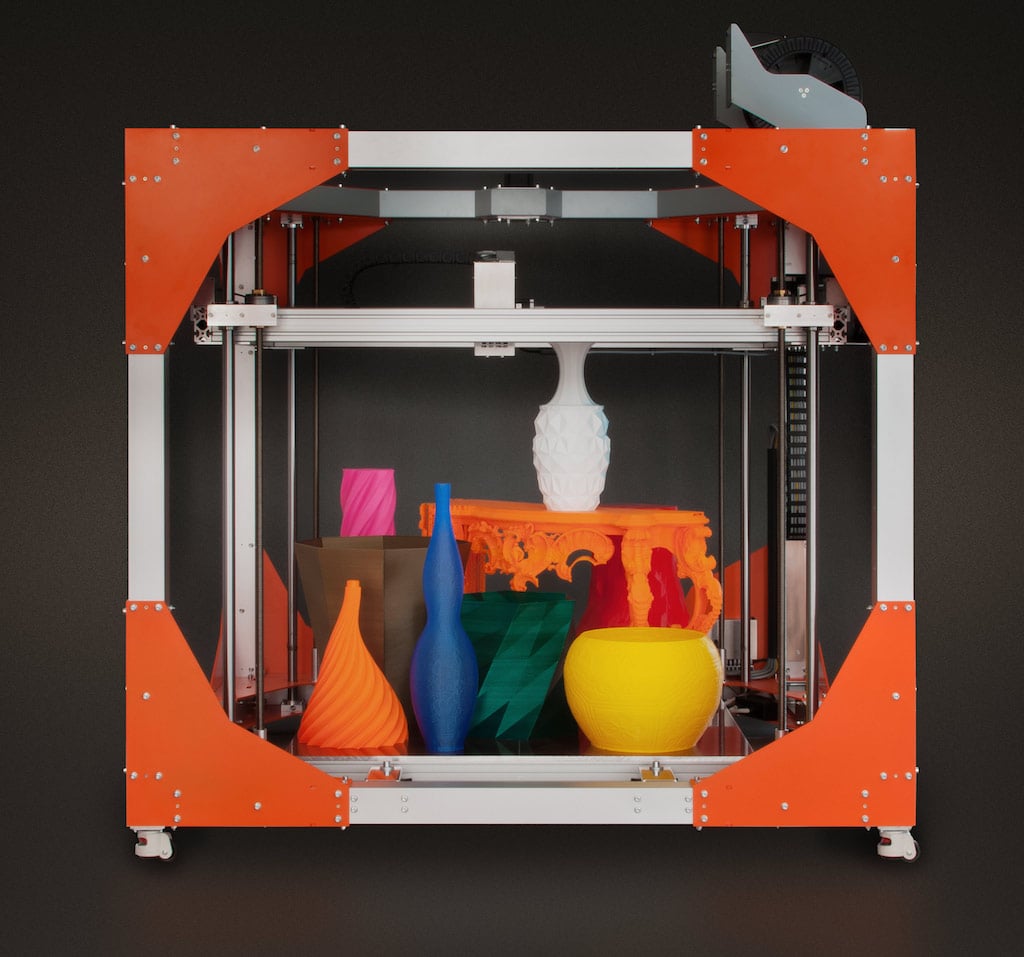

Fabbaloo: Currently the BigRep ONE is a PLA-based 3D printer, but we’re wondering if you’ve considered modifying the machine to accommodate other plastics, such as ABS, HIPS, or high temperature materials? What adaptions to the BigRep ONE would be required, and could this be feasible in the future?

René Gurka: The ONE is our first product. We’ve gained a lot of experience since our launch in 2014 and are now ready to further extend our product range.

Of course, I cannot tell you everything yet but let me say: the ONE will stay an open printer for printing materials at room temperature. New products will allow us to control factors such as built chamber temperature, nozzle sizes or materials. A lot of exciting developments are right now taking place at BigRep, so stay tuned for news on this front!

Fabbaloo: The recent series A financing round poured quite a bit of money into BigRep. How do you see these funds being used? Should we expect to see expanded sales and distribution? Or perhaps development of new equipment lines?

René Gurka: Since 95% of our customers are international, that means from outside of Germany, our immediate goal is to grow our regional presence in Asia and USA, mostly with regard to sales and our growing network of resellers.

Moreover, we will launch at least one additional printer in 2016. We have great ideas based on customer feedback and we will for sure target high performance “super materials” for industrial companies’ high requirements. Other than that, we still want to cater the needs of our customer base of designers, architects and artists who are very price sensitive. With the growing amount of great features, the BigRep ONE is still very affordable but I believe that the introduction of an additional basic printer would grow our fan base even more.

Fabbaloo: There currently aren’t very many 3D printer manufacturers with the print volume and pricing of BigRep, but do you see this niche as one that might attract competitors?

René Gurka: Competition has already arrived! Many new players focus on much larger built volumes now. Nevertheless, they quickly realize that printing large is a different game and that you have to solve issues which small desktop printers simply don´t have. This might also be the reason why many desktop manufacturers that try to enlarge their current products can hardly go bigger than half a cubic meter.

Fabbaloo: One of your competitors is Stratasys, who produce the similarly-sized, but more expensive Objet1000 Plus. What is it like to compete against a machine that has the backing of a very large corporation?

René Gurka: We have customers that in fact still use a Fortus 900 or Objet1000 but just not on a daily base any more. Our motivation is to bring a complete new customer base to large scale 3D printing – that’s why we do not compete with Stratasys for their current customers. BigRep customers are looking for affordable solutions that are currently close to 90% cheaper than anyone else’s and we want to democratize the access to professional large scale printing.

Let me give you an example: Architectural studios use the BigRep ONE to print models of their designs for their customers’ review. Other than competing models, the BigRep ONE allows them to easily print a new model with changes for about €500 (USD$540) – that’s an unmatched price.

Fabbaloo: Final question: Can It Be Even Bigger???

René Gurka: When we started BigRep in 2014, we paved the way for large scale affordable printing and right now, we are the market leader in this sector. I guess, we are today in a similar situation to Makerbot when they started to disrupt desktop printing with a $1,500 machine.

To answer your question: Yes, we want to and can get even bigger. We have a firm goal that is to become the global leader in affordable full scale printing. This goal will only be reached when BigRep is the global synonym for affordable large scale 3D printing with factories in Europe, Asia, Africa and the Americas.

Via BigRep

Image Credits: BigRep