A group of Swiss students has done something previously thought impossible: 3D printing a tank of compressed air.

The group, CVRA of Renens, Switzerland, was working to develop a robot to enter in the annual EuroBot contest. As part of the challenge, the robot was required to perform an interesting action (raising an umbrella), but where was the energy to power the action coming from?

The Swiss team decided to experiment with compressed gas. Evidently their robot design did not include a volume shaped for conventional gas cylinders:

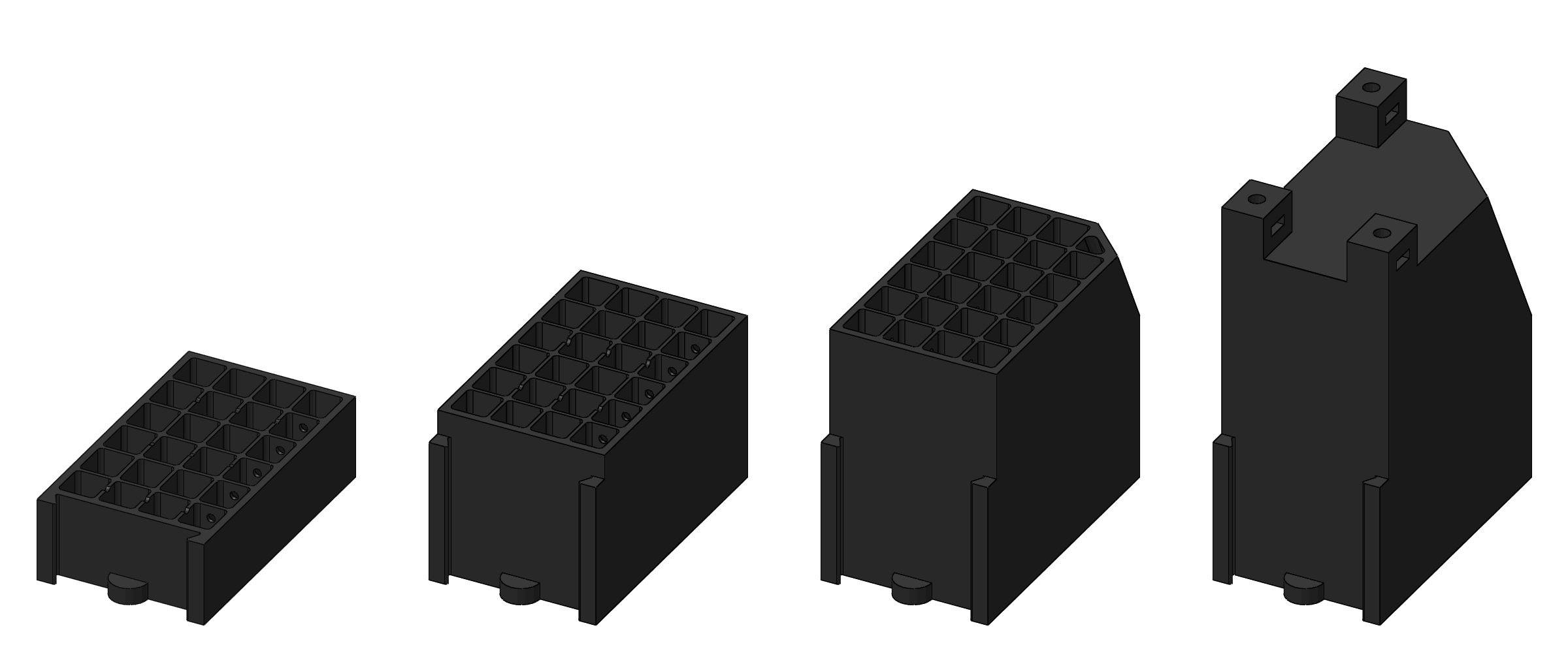

Our requirement was to have as big as a tank to fit in a prismatic rectangular space. A cylinder would not have done the job properly and would not have been innovative. A 3D-printed air tank would do both, so we tried a few ideas.

Now at this point, you might be skeptical. You might be horrified by the danger of compressed gas, too. I certainly am.

But hear this: the typical pressures encountered in gas cylinders are reasonably high. In a typical scuba tank, for example, you might find 3,000psi. Were that cylinder to be compromised, you can be guaranteed a very healthy explosion, as the stored gas suddenly tries to expand 200X in volume.

But that amount of pressure was not required in this robotic experiment. The CVRA team determined they required only 4 bar (58 psi) to power their device.

They did some calculations and realized that it might be possible to 3D print a structure to hold that compressed gas.

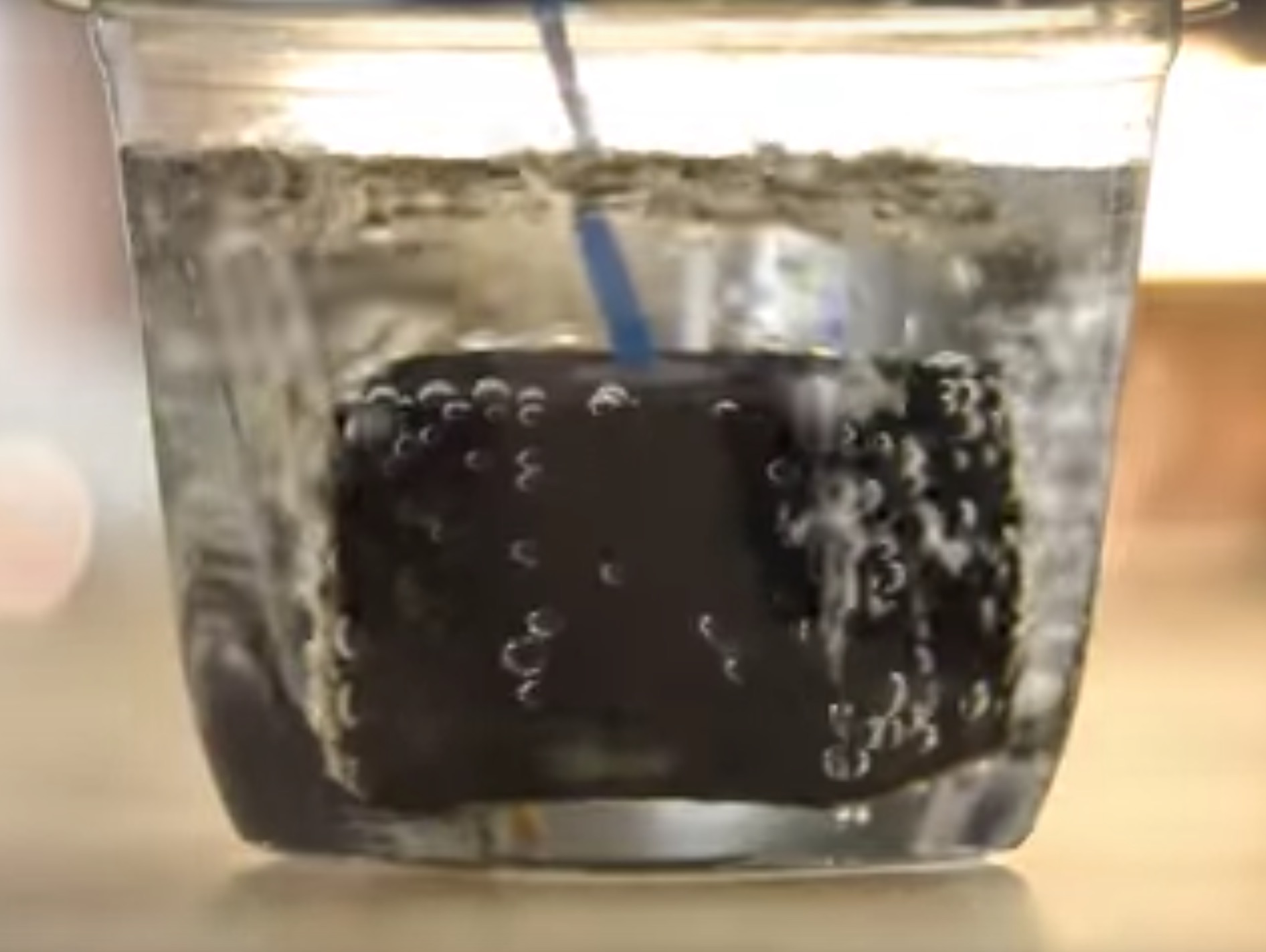

Their first experiment was a 40 x 40 x 40mm test cube, printed with only four perimeter walls and an infill of 20%. Evidently their intent was to fill the “not infilled” space within the cube with 6.5 bars of compressed gas through a 3mm hole. Apparently, this test worked, as you can see in this video:

Their second experiment attempted to up the size to the required level 65 x 40 x 80mm, and used a six-layer perimeter wall. This experiment exploded when charged with gas at only 5.5 bars, fortunately with no injuries. CVRA strongly recommends these precautions should you attempt a similar experiment:

-

Rule #1: wear protective glasses when subjected to even remotely possible projections.

-

Rule #2: hide behind a protection wall when things can potentially explode.

How can this work? 3D prints are notorious for gaps in layers and other non-watertight features. In fact, CVRA published this video of a “raw” pressure cube showing how leaky they really are:

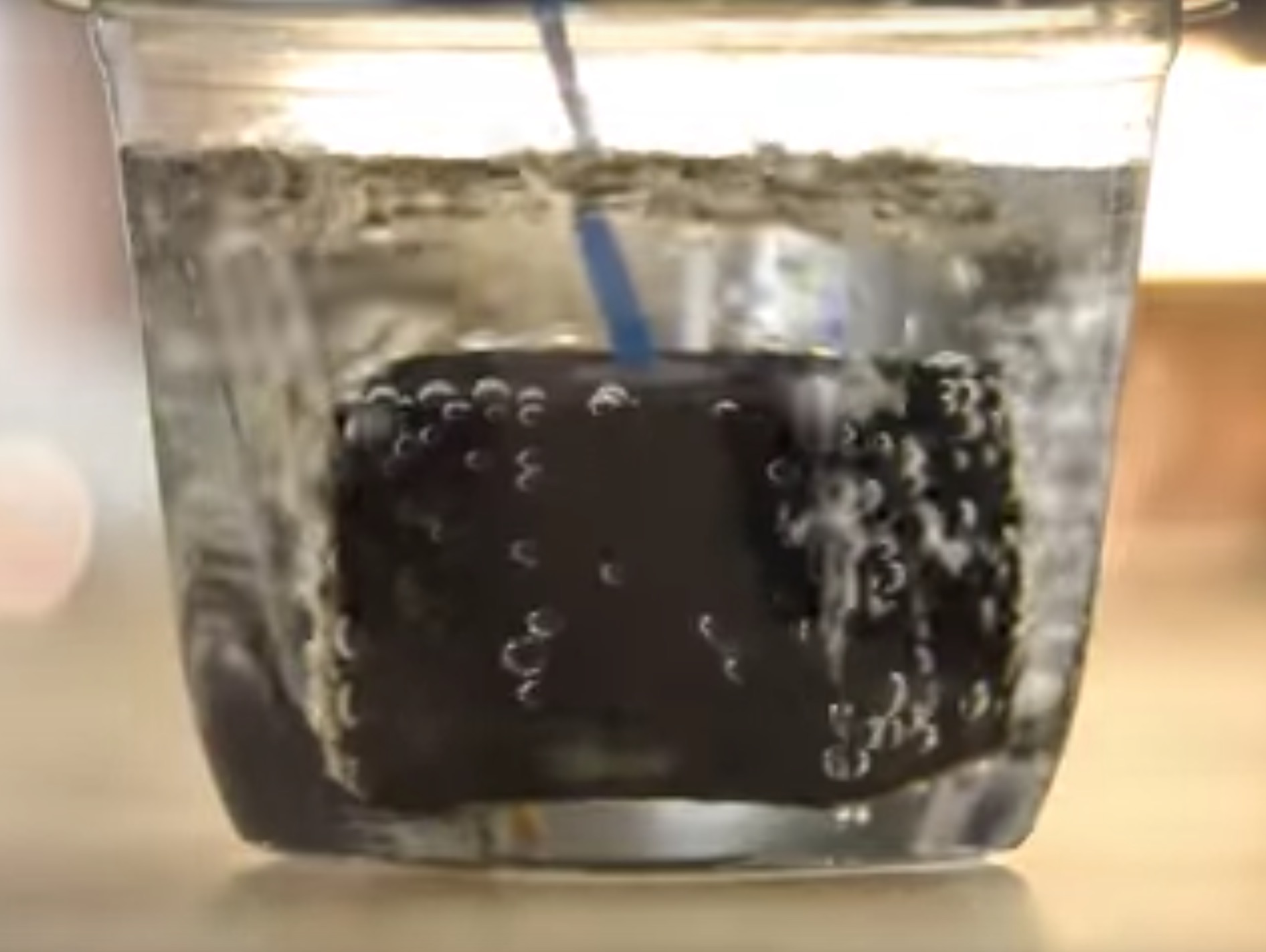

The answer is to coat the inside with a liquid sealant, likely applied through the 3mm hole and rotationally distributed around the inner surface. Does that work? Take a look for yourself:

So it is apparently possible to 3D print low-pressure compressed gas tanks, so long as you seal them properly and take appropriate precautions.

However, I suspect there could be further developments here through the use of interesting inner structures that may assist in retaining the shape under pressure. As the compressed gas pushes against the walls, any stretching of the overall container would likely introduce delamination of 3D printed layers.

While compressed air tanks are now possible, I strongly recommend you don’t experiment with them, as you’re essentially making a small bomb.

Via CVRA