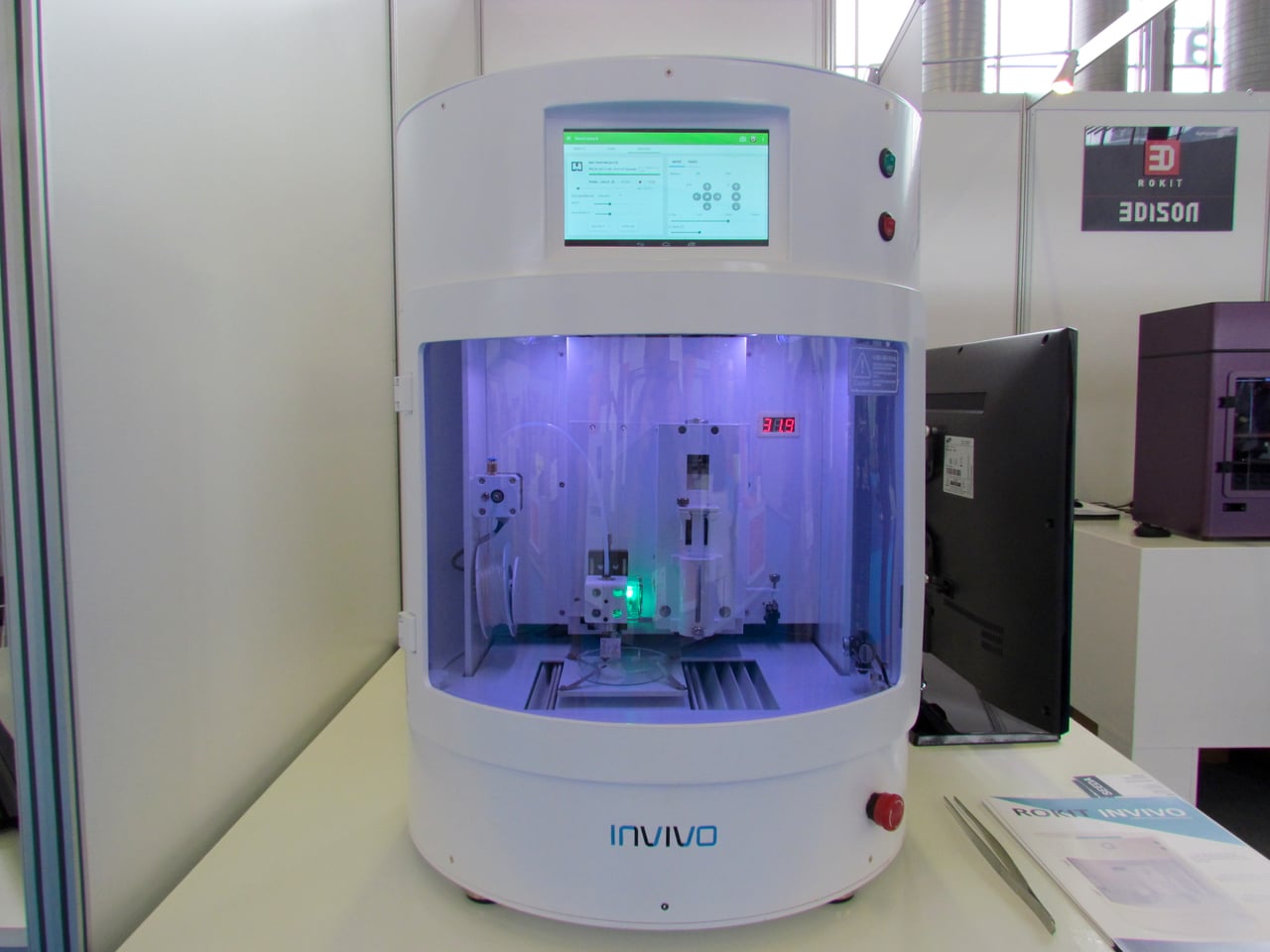

There are not very many bioprinters on the market, but one of the more sophisticated options is the Invivo from ROKIT.

Korea-based ROKIT is perhaps best known for their broad line of 3Dison 3D printers, which cover almost the entire range of needs for plastic 3D printing, from hobbyist to professional usage. But evidently their plans involve going well beyond plastic 3D printing and now enter the biological world with the introduction of the Invivo Bioprinter.

This device is similar to plastic 3D printers, but used in an utterly different manner. Instead of heating plastic to a flowing state and extruding, the bioprinter merely deposits biomaterial. In fact, heating the material would destroy it!

Bioprinters operate with an approach similar to a support-structure as used with plastic prints. However, the support structure, called a “scaffold”, is made from biodegradable material. Upon this structure is also deposited the “active” material, which is typically live cells.

The resulting print is placed in a culture medium, where the living cells multiply and the scaffold eventually dissolves. This leaves a biostructure of only the desired living cells.

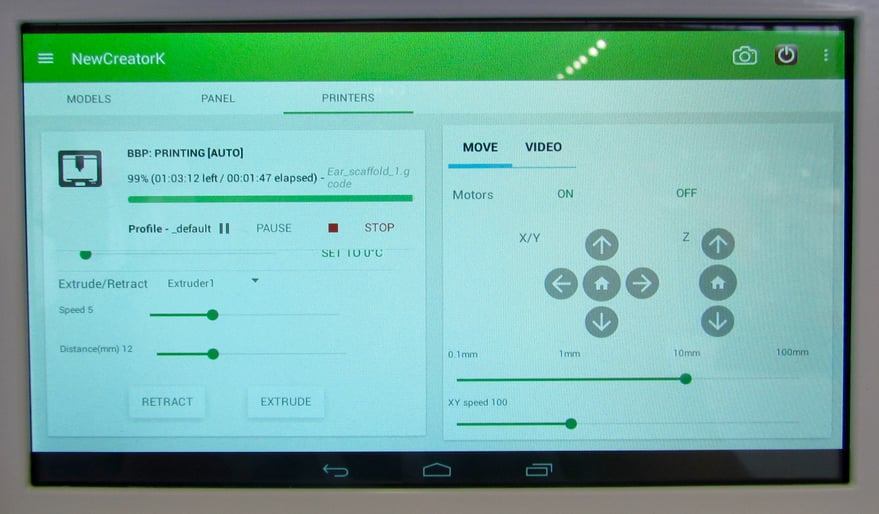

This technique is used to create, for example, a replacement human ear: an ear-shaped scaffold is filled with live cells that “become” the ear. Presumably the ear is custom designed to fit the specific individual.

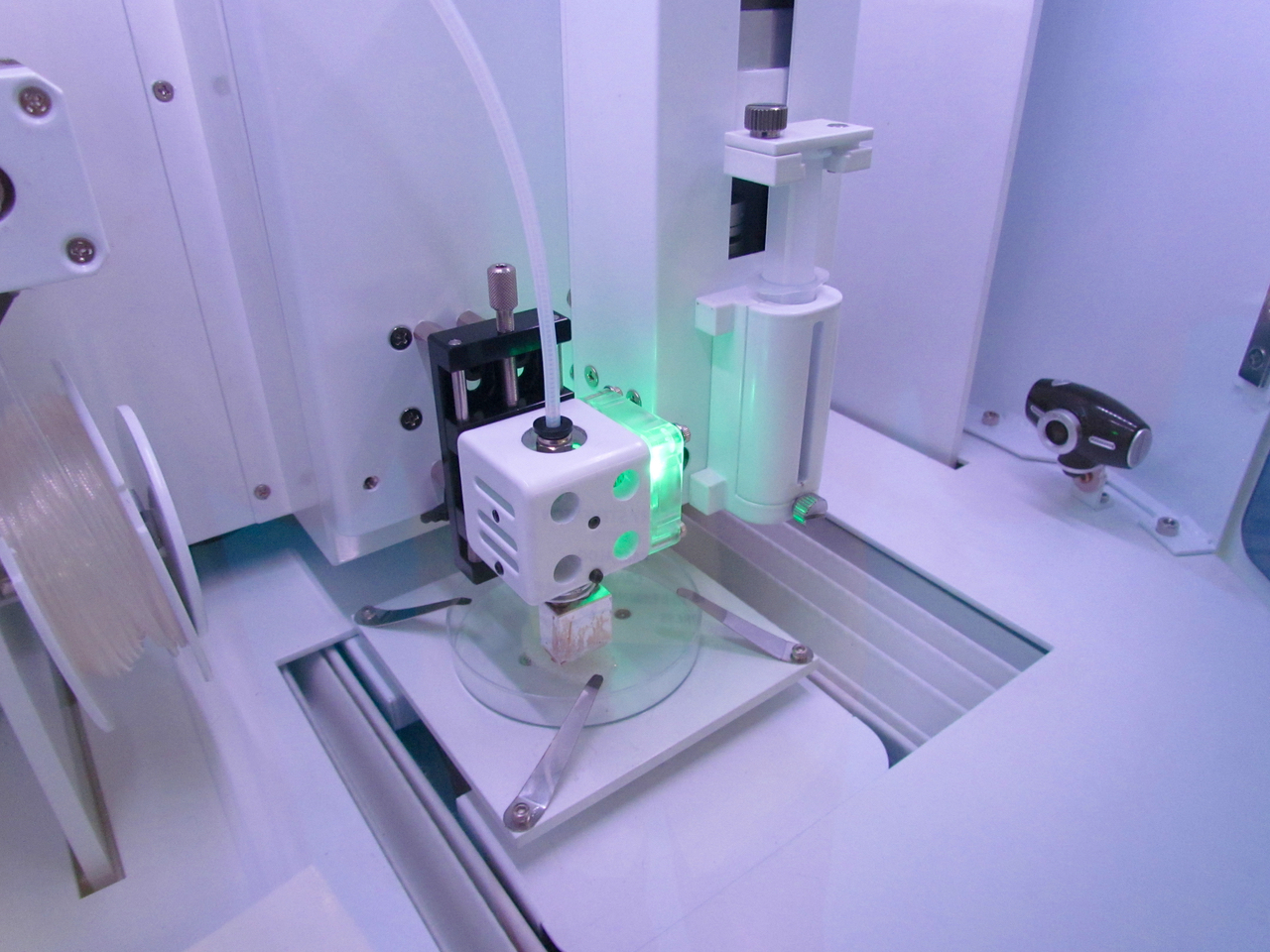

But back to the new Invivo machine. The most prominent feature of the device is that it includes dual extruders, permitting the printing of both scaffold and biological material at the same time. This should simplify and speed up bioprinting when the Invivo is used.

Aside from the dual extruders, the device itself has a sophisticated design that would definitely fit within any proper lab environment. I mention this because many of the bioprinters I’ve previously seen have been quite rudimentary in their design. Here, for example, you can see the Invivo’s detailed – and large – touch control panel.

The exterior case is notable not only for it’s professional appearance, but that there IS an exterior case! Many other primitive bioprinters are simply a basic armature holding up the mechanical axes. This device is for real, and intended for professional use.

What’s also interesting is the materials specification for the Invivo. The scaffold extruder is capable of extruding several different materials:

- PLGA (poly lactic-co-gylcolic acid)

- PLLA (poly L Lactic acid)

- PCL (polycaprolactone)

- PLA (polylactic acid)

Whereas the bio-extruder can print these materials:

- Collagen

- Alginates

- Silk Fibroin

- Hyaluronic Acid

The nozzle size can also be changed to several different diameters, depending on the application.

The Invivo also includes the ability to pre-heat materials to precise temperatures before extruding, and can be upgraded to include a heated – and cooling (!) bed. This permits precise treatment of fragile print materials during operation.

Needless to say, the Invivo uses bio-safe components and has been medically certified for such uses as printing small and simple replacement parts for humans.

I’m told the Invivo is priced between €20-40,000 (USD$22-44,000) and is targeted at hospitals, where, in fact, there are several currently being beta-tested.

Via ROKIT