Proto-Pasta has introduced a new line of PLA-based 3D printer filament with some surprises: Matte Fiber HTPLA.

Every 3D printer operator is familiar with PLA plastic: it’s an easily processed, almost warp-free plastic that tends to print reliably on most desktop 3D printer setups.

When it was introduced to the 3D printing community years ago, one of its cool aesthetic features was it’s shine. PLA prints came only in a shiny finish.

The other limitation with typical PLA is its heat performance: since it has a less heat resistance, it might be easier to 3D print, but this also means it’s subject to heat deformation if exposed to commonly encountered higher temperatures. As a result many 3D printer operators were forced to use ABS as the material for their functional parts.

And that’s pretty much how it’s gone with PLA since that time.

But now, Proto-Pasta’s new Matte Fiber HTPLA breaks that pattern, and a few others.

The new product is composed of a mix of a special PLA-style polymer and plant-based fibers. This rare combination turns out to a number of interesting advantages.

The fibers add stability and sheen to the material in the same manner as has been done with other hybrid filaments that have added carbon fiber or glass. However, there’s a problem with these materials: the added fibers are of a substance that’s often harder than the 3D printer’s brass nozzle.

In order to successfully 3D print them over the long term without gradually eroding your hot end nozzle, you have to replace your nozzle with a much harder stainless steel, tungsten or otherwise wear-resistant nozzle often made of brass electroplated with hard nickel. Either that or you’ll quickly experience inconsistent extrusion due to erosion.

But Proto-Pasta’s Matte Fiber HTPLA does not have this effect, because the fibers are not has hard as brass, yet they still reinforce the polymer and change the aesthetic. This means you could attempt to 3D print composite parts without a special nozzle.

But you may be thinking that even though the part printed in Matte Fiber HTPLA might be stronger than PLA and ABS, it is still PLA and therefore will deform in a hot car, for example.

That’s not the case with this material. It’s a unique PLA mix Proto-Pasta calls “HTPLA” that exhibits improved thermal performance compared to your typical PLA material.

While you can 3D print Matte Fiber HTPLA with the usual PLA temperatures (190-230C), there is a way to dramatically improve a part printed in this material after printing by using a post-printing heat treatment.

Proto-Pasta’s HTPLA can be heated for a short period (duration depends on the geometry and size of the print) in an oven. This first softens the material like normal PLA until it firms up and “cures”. Not only is stiffness at elevated temperatures improved but strength and durability as well.

This explains the naming for the product: the “HT” in “HTPLA” means “Heat Treatment”, the method that generates the product’s improved mechanical and thermal performance.

Proto-Pasta’s Alex Dick explains this unique approach in this video:

I’ve not seen this post-processing method of improving PLA heat and strength properties used by any other 3D printer materials vendor.

The technique essentially removes the limitations posed by typical PLA and therefore Matte Fiber HTPLA should be a very good option for those wishing to have the performance of ABS (or better) combined with the printing ease of PLA.

And one more thing: it has a matte finish! Proto-Pasta explains:

Printed parts have a low luster, textured surface which creates a highly desirable contrast between light and shadow. Texture, color, and sheen can be somewhat manipulated by printer settings as well as post-processing.

Why is this important? Porto-Pasta’s Alex Dick explains:

Look at our computers and cars, they are peppered with low luster, textured parts with some contrasting shiny plastic as well. Maybe you prefer shiny plastic, but variety is better, right? We’re leading the industry into a new world of color, texture, and sheen control. This is another step towards mainstreaming 3D Printing and having more finished goods created using the process. We already have customers using these materials to make bikes, lamps, aircraft, sailboat and car accessories, etc. Exciting progress!

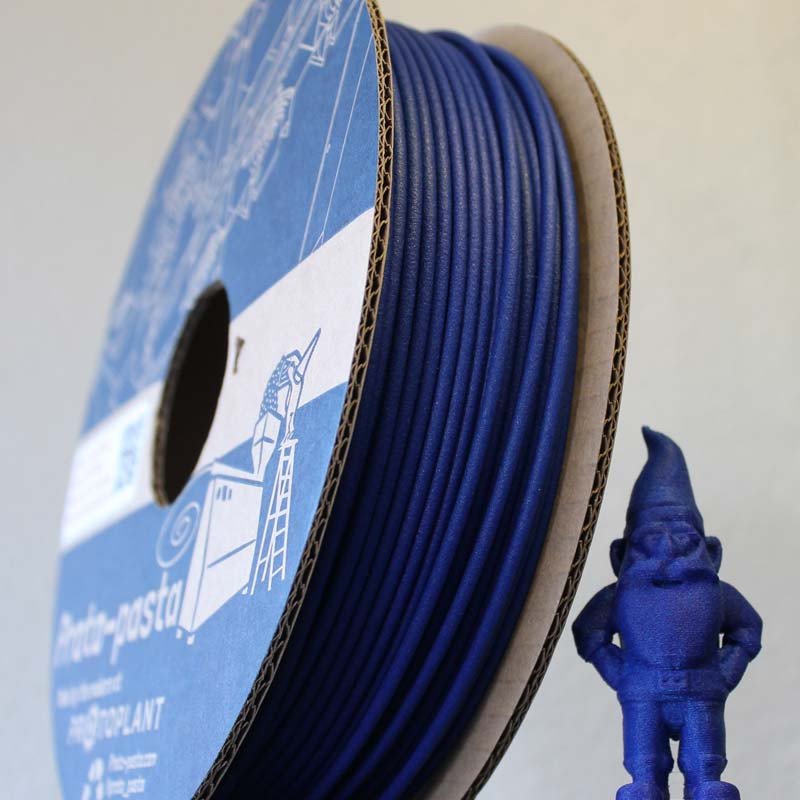

Meanwhile, you can order Matte Fiber HTPLA from Proto-Pasta in 500g spools for USD$40 in Blue, Black, White and Red.

Via Proto-Pasta