Sweden-based Bondtech has released a powerful new extruder for desktop 3D printers.

Bondtech has been building such hardware for three years, initially driven into business by frustration with then-current hardware options for desktop 3D printers. The founder, Martin Bondéus, somehow devised a method by which significant force could be applied to a filament without slippage, a very common problem on many extruders.

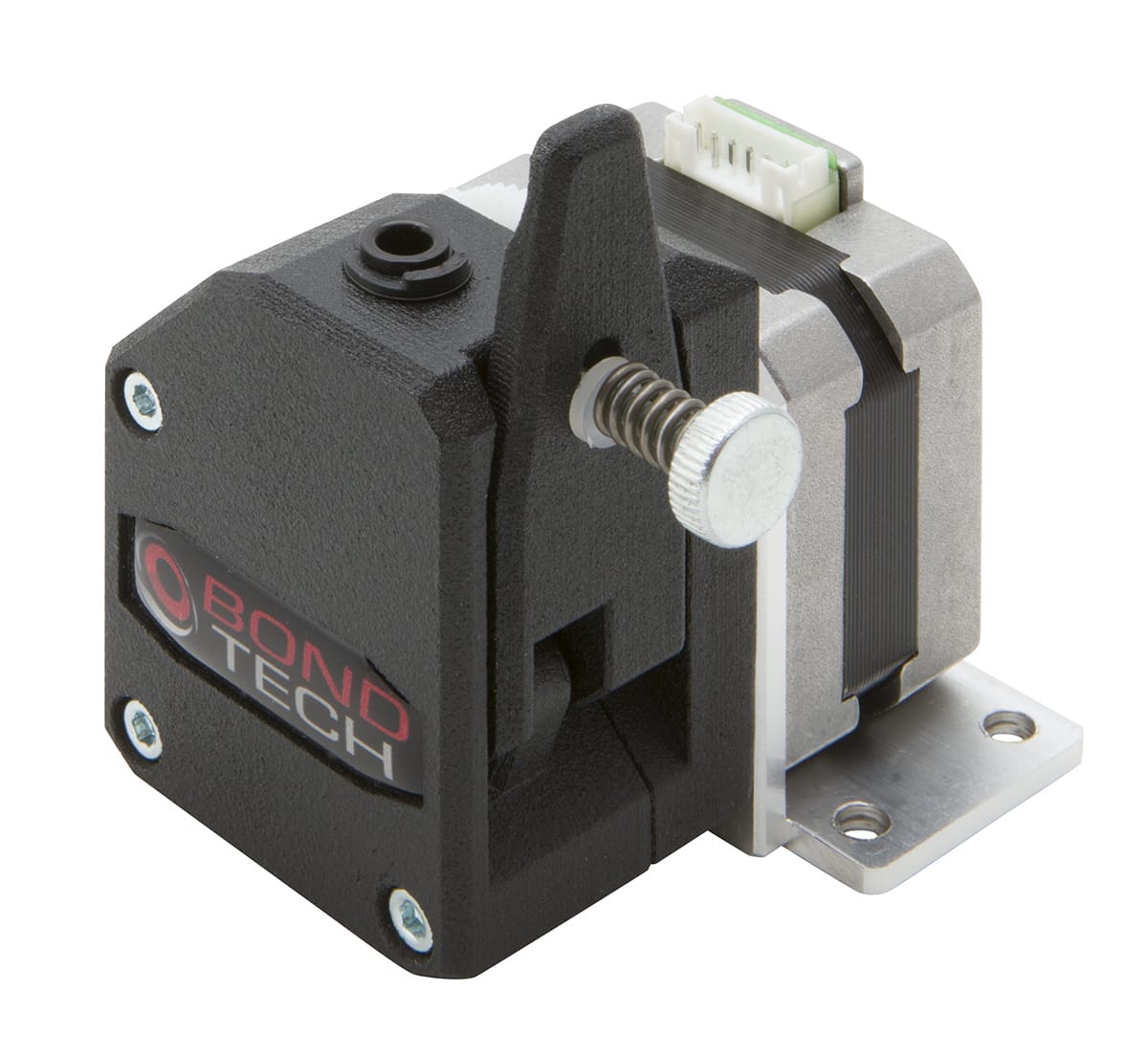

Bondtech’s new BMG Extruder is a very interesting piece of hardware. Of course, it’s only a single component of your entire desktop 3D printing system, but a very critical element. You’ll need to combine it with a hot end and the rest of the 3D printer.

The BMG Extruder uses CNC-machined steel gears with a ratio of 3:1 to provide the necessary pushing force.

One interesting feature of the BMG Extruder is what they call “Dual Drive”, which they explain as follows:

Our unique Dual-Drive technology delivers uninterrupted material flow without fear of grinding or slipping in even the most demanding conditions. Bondtech users the world over will attest that even in prints with thousands of retracts our extruders perform flawless, with unmatched precision, and zero damage or degradation to the filament.

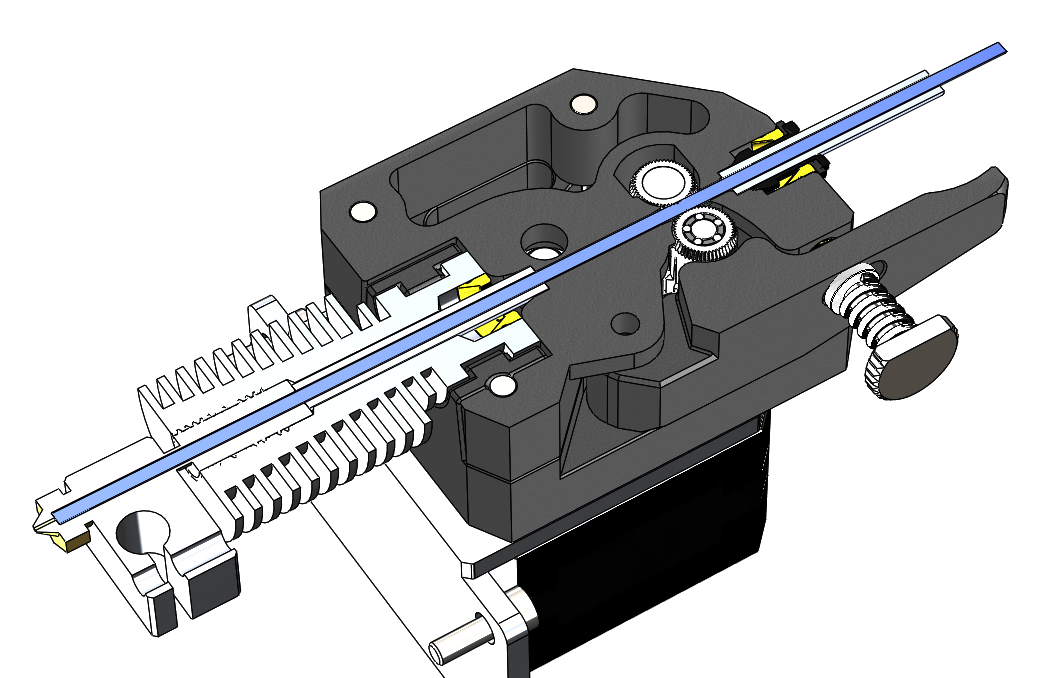

That doesn’t quite explain how it works, but a look at a cut-away diagram may reveal what’s going on.

In most extruders there are two gears / wheels that grip the filament and push it forward. Typically one of these gears / wheels is passive, while the other is active. In Bondtech’s “Dual Drive” configuration, I suspect both gears are active, significantly reducing the opportunity for slippage.

Bondtech has a number of charts showing how the BMG Extruder provides more force than unnamed “competitors”, but it would be more clear if we knew who they were.

The result of this feature is impressive: this extruder can apparently handle a very wide variety of filaments, including not only the usual ABS, PLA, PETG, etc, but also “slippery” nylons, spaghetti-like flexible filaments and even brittle composite materials.

Aside from the drive system, the BMG Extruder has a number of useful features, such as quick release for easy filament changes, and it can be installed in a variety of configurations including both Bowden and Direct.

One feature I’m undecided on is the adjustable tension knob. This feature allows the operator to set the tension precisely to the correct amount for any material. Yes, this sounds good, but in fact it is also an opportunity to set it incorrectly. It would be nice if such things were automatic, but that’s another story.

The BMG Extruder is available now for only USD$80 at the Bondtech site.

Via Bondtech