I’m looking at GE’s new Advanced Turboprop Engine and it seems it makes substantial use of 3D printing technology.

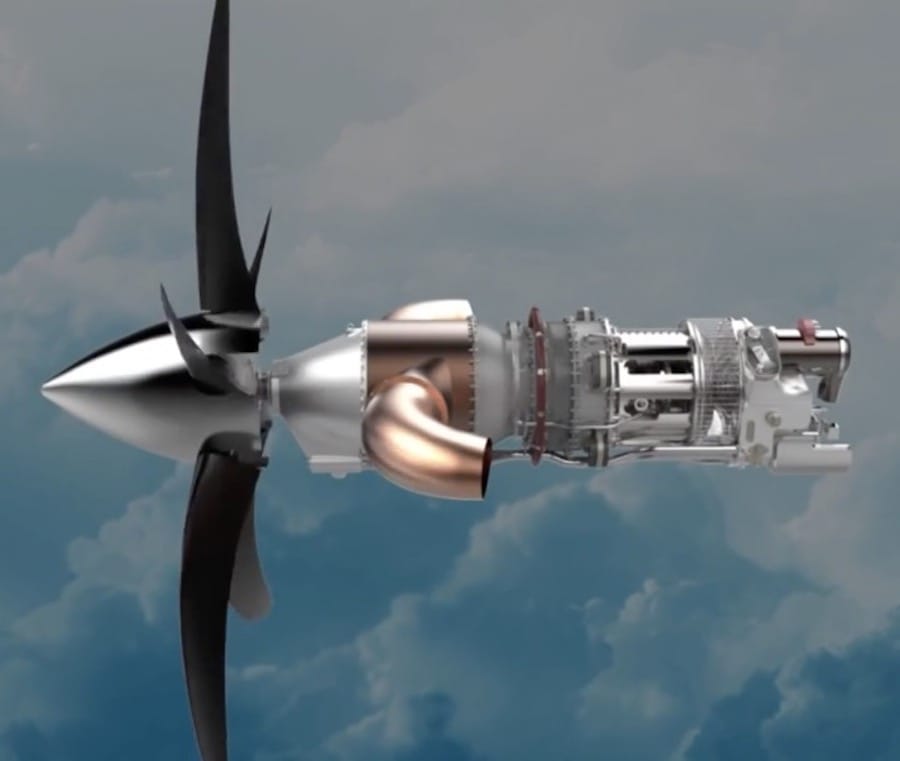

The turboprop has been the forgotten engine in industry, as much greater focus has been placed on jet technologies, although the two engines have some similarities. In a jet engine, the turbine exhaust is pushed to the rear, providing the forward thrust. In a turboprop, the exhaust is not sufficient to provide thrust, but instead is used to turn a shaft on which a propellor is mounted. The propellor provides the true engine forward thrust.

The turboprop engine has been around since the 1940’s and have been proven reliable on smaller aircraft. But for many years there has been apparently limited innovation.

Now that’s set to change as GE is developing a new advanced turboprop engine that leverages 3D printing technology.

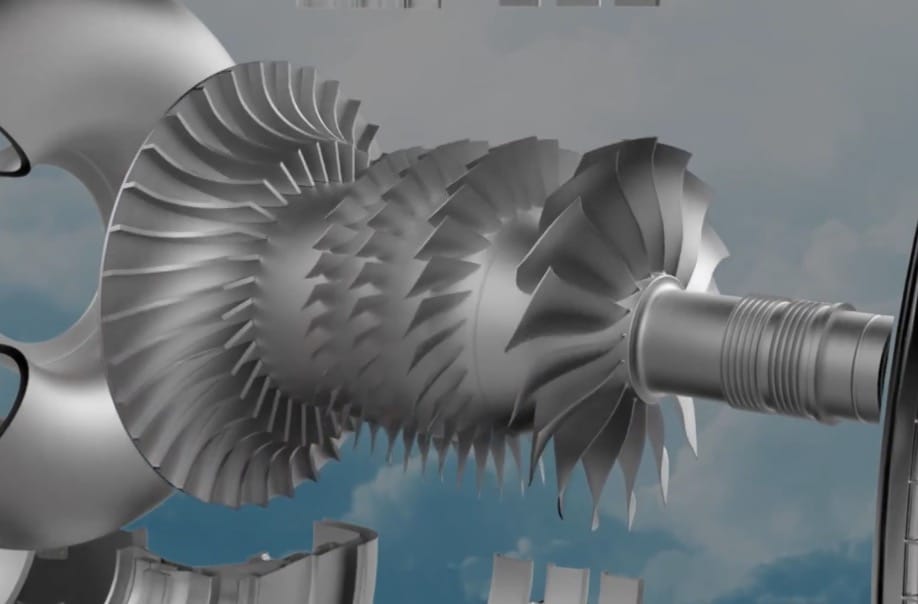

Some of the advances in this engine are inherited from their jet engine innovations, such as the internal cooling channels within the turbine blades. These structures allow the turbine to operate at higher temperatures, which in turn increases engine efficiency.

Internal cooling channels are exactly the kind of design you’d expect to see when leveraging 3D print technology, as that type of structure would be exceedingly difficult to produce otherwise.

In addition, multiple components of the engine are designed in 3D for maximum aerodynamic efficiency. Again, 3D printing has been leveraged for benefit.

When released sometime next year, the GE turboprop engine will provide operating efficiency benefits by delivering up to 10% more power while using 20% less fuel. This has proven quite attractive and the new Cessna Denali private plane will make use of the USD$4.8M engine.

This is obviously good news for GE, aircraft manufacturers, aircraft buyers and others in that chain of activity. But it also provides us a sign for the future.

Here we have a major company that’s deeply adopted 3D printing technology and has begun to apply it broadly across their product line.

To their consumers it may seem they’re simply making better products, which is true. But to me, it’s a sign of 3D printing becoming deeply embedded into industry, where it will remain forever.

Via GE Aviation