Some 3D printers can print in carbon fiber, but this 3D printer is made from carbon fiber.

Carbon fiber is an increasingly popular material in the 3D print world, due to its low weight and high strength. Multiple 3D printers now have the capability of 3D printing objects using carbon fiber-infused filaments.

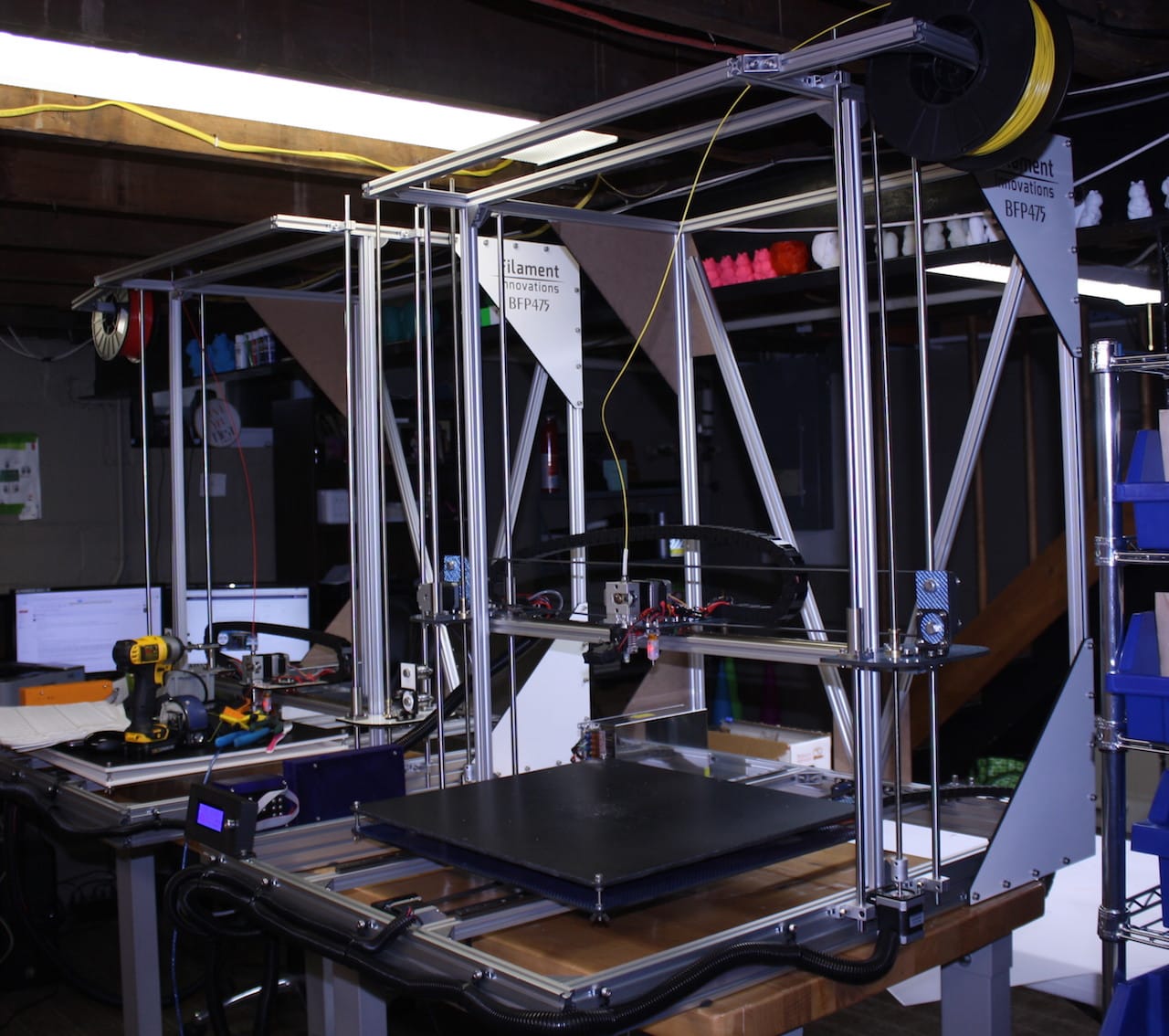

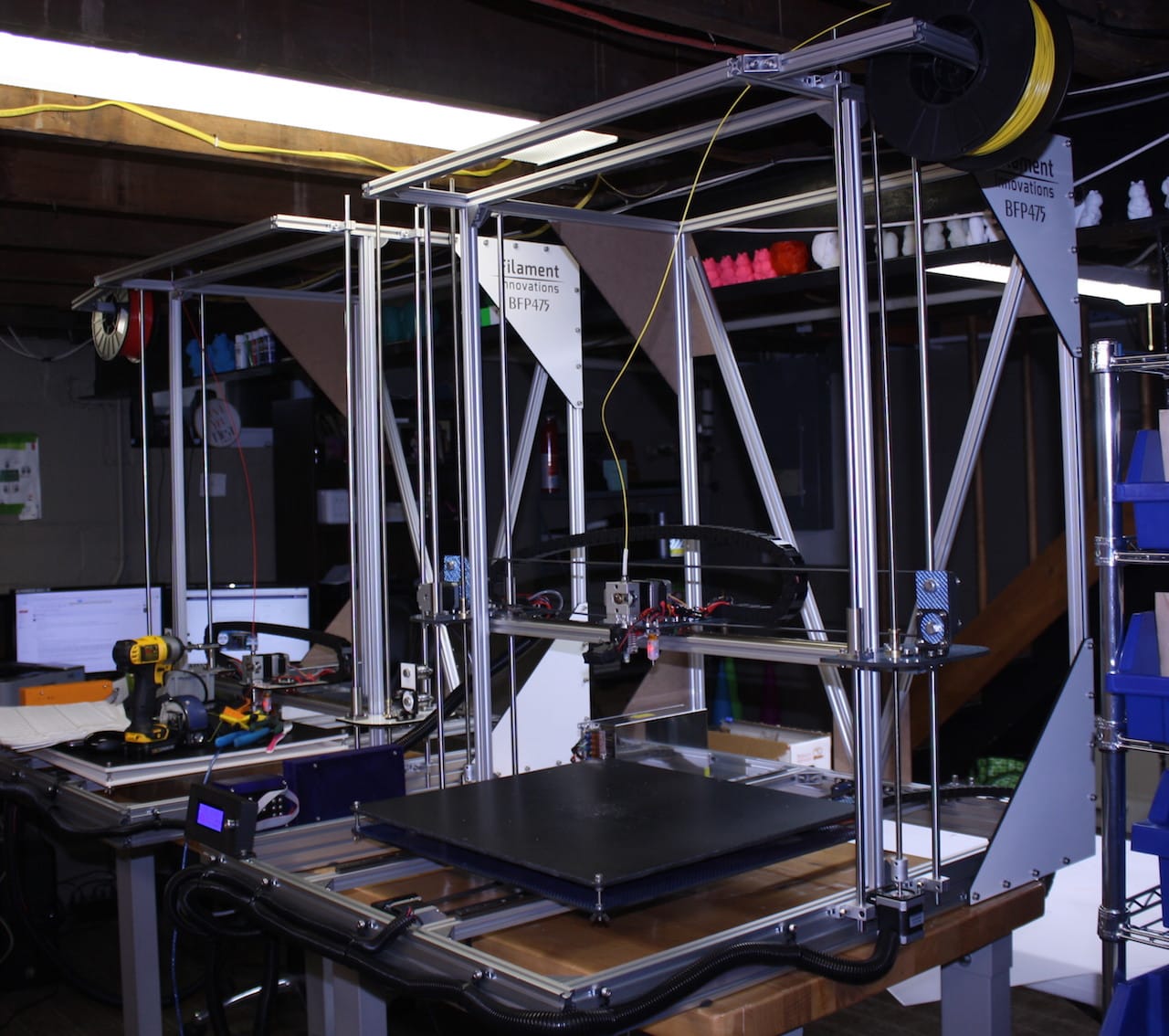

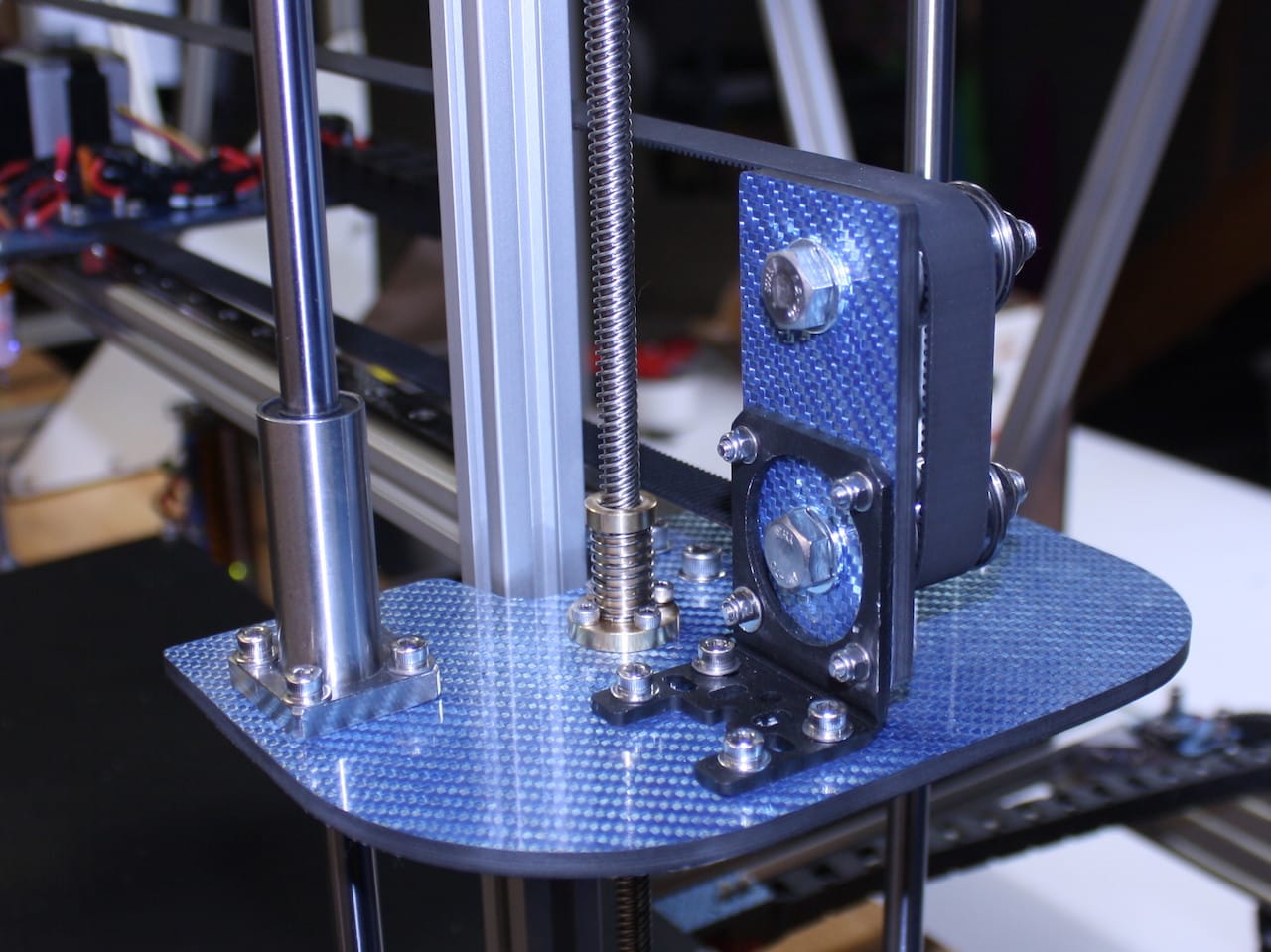

However, this machine is made from carbon fiber, at least partially. The Filament Innovations BP475 is a larger format unit that’s sold as a kit for onsite assembly – and it carries a very good price.

According to founder Mike Gorski, the origin of this machine was based on the need to make something better:

About three ago, I set out to build a large scale 3D Printer based on open-source technology, premium components, and one that was affordable for everyone to have. After tons of trial and error, I finally created what is now called the BFP475. The BPF475 has a 475x425x700mm build area and comes standard with Carbon Fiber parts.

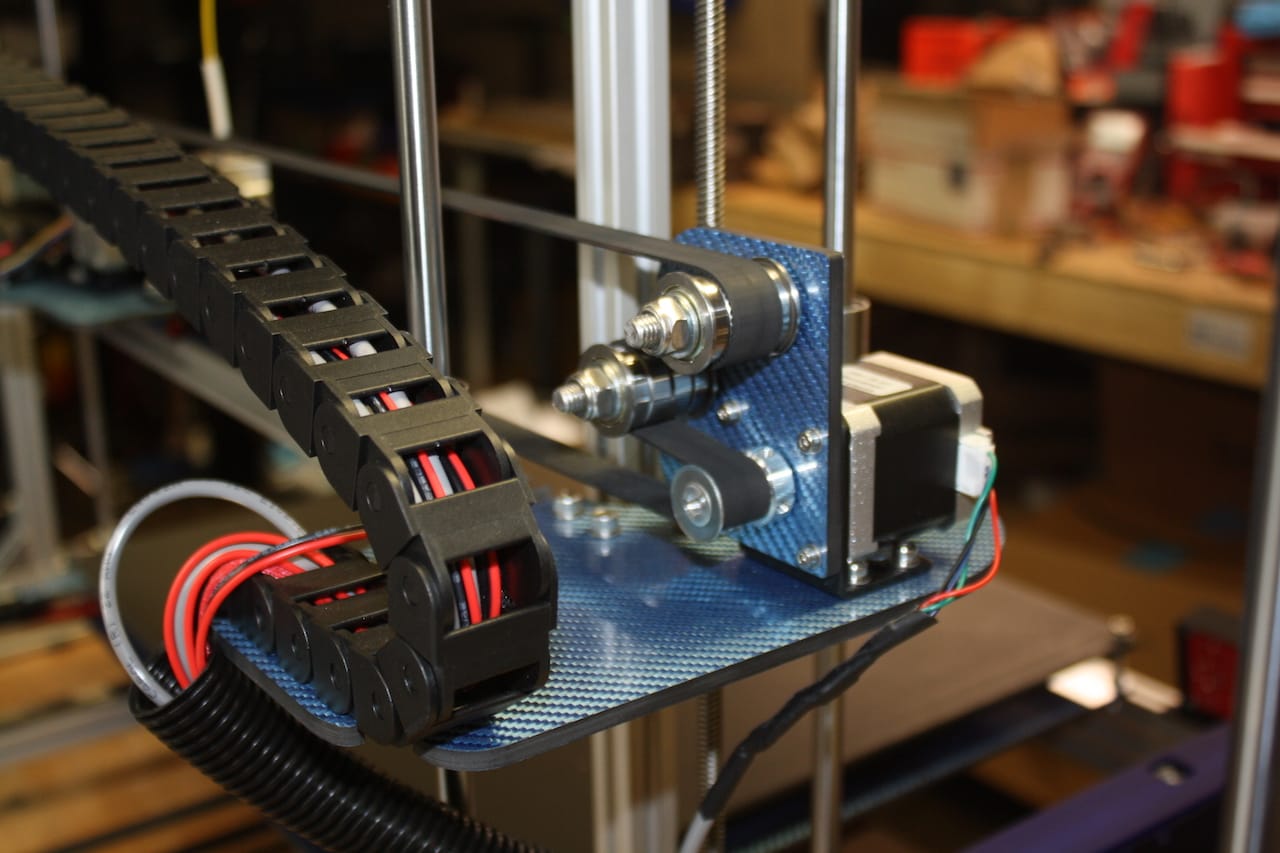

And that’s what you get: a 3D printer that includes a number of carbon fiber parts. In particular, the machine includes a 5mm thick solid carbon fiber print plate, as well as a number of other critical components.

Carbon fiber provides highly rigid and durable components that should make printing more reliable. As well, the weight of the machine is slightly less, although the majority of the machine’s weight will be the frame, which is standard aluminum extrusions. Nevertheless, achieving the same plate rigidity using regular metal would be quite a bit heavier.

Aside from the carbon fiber, the BP475 has some very interesting features, most notably its huge build volume, at 475 x 425 x 700mm. That’s gigantic, as far as desktop 3D printers go. Other features include:

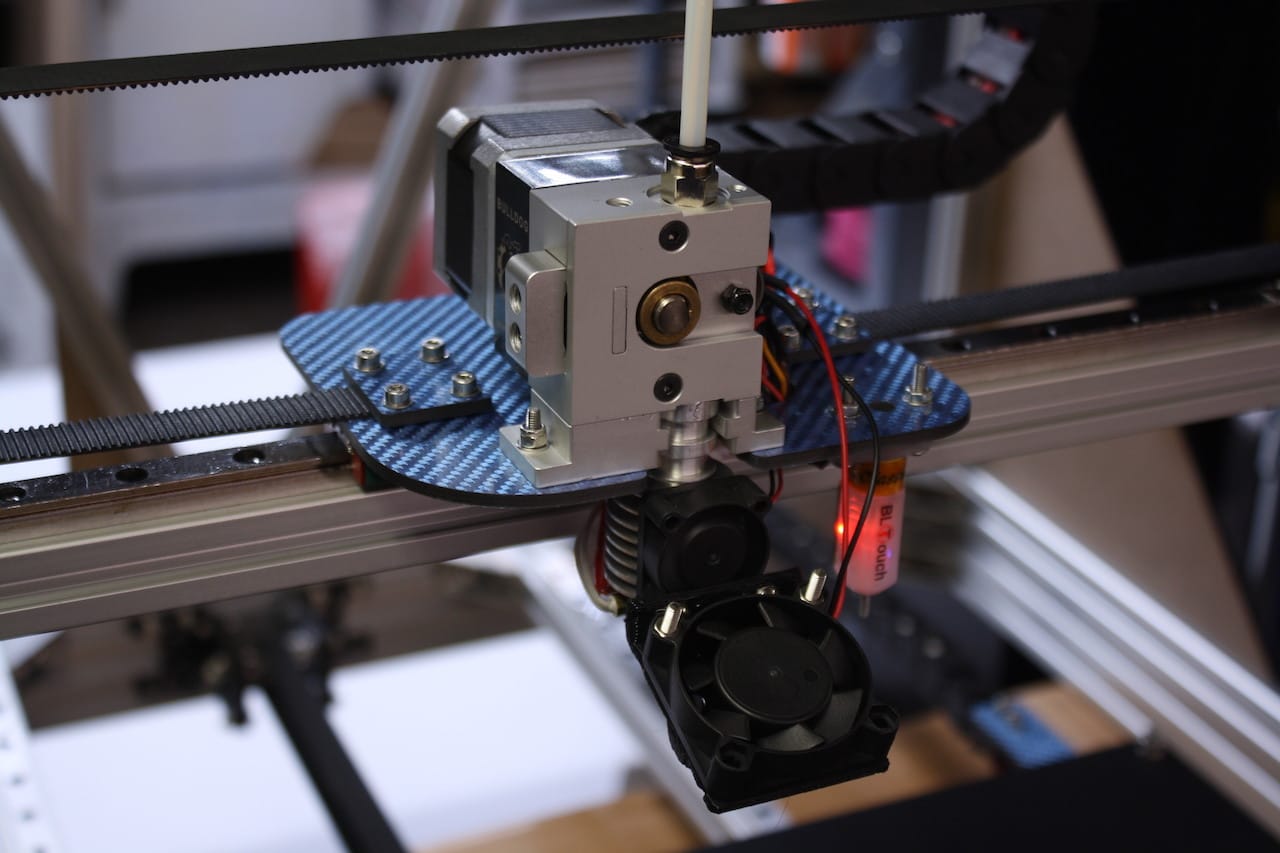

- Automated leveling system

- BulldogXL geared extruder

- Prometheus V2 hot end

- MKS Get 1.4 control board

- X / Y axis slide smoothly on bearings / rails

- Open source design for easy modification and repair

There is an optional heated print surface, which I would recommend for such large prints, or you can opt for a PRINTinZ print surface, which I’ve found very useful.

But perhaps the most interesting feature of the BP475 is its price: only USD$2,999. That is a spectacularly low price for a machine of this size and features. Consider this: 3D prints on this volume are exceeded only by the 3D Platform and BigRep-style machines, all of which cost in excess of USD$20K.

Gorski also informs us that they’re experimenting with an acrylic version of the kit that would reduce the pricing even further to perhaps USD$1,999. However, I think I’d prefer that carbon fiber print bed.

Materials printable on this machine would, at least at large object sizes, be constrained to PLA due to the open format of the machine. Ambient air will no doubt cool prints and make it overly challenging to 3D print warpy materials such as ABS.

However, smaller items can be printed in a much wider variety of materials as the hotend is capable of hitting 300C, making it possible to 3D print ABS, Nylong, PETG, TPU and other more exotic materials.

From what I understand, the company produces kits in batches and once sold, there is a four week waiting period while they organize the next batch.

This item is a kit, and you must assemble it yourself. However, Filament Innovations has taken the effort to minimize the work required. Gorski explains:

There has been absolutely no compromise to quality when it comes to this printer. The printer does ship as a kit, but all the major components are pre-assembled. The end user just needs to put a few key bolts in to connect the main assemblies together, plug the wiring into the MKS Gen 1.4 Board (harnesses are pre-made), and the user is good to go.

Filament Innovations, as their name implies, also sells filament, but there’s a difference: they produce large-format spools specifically to address the needs of the hungry BP475, which, due to its size, can print for very long periods. It’s for those long prints that large spools can reduce or eliminate the need for mid-print spool swapping.

If you’re seeking a very low cost, large-format desktop 3D printer that is reliable, the B475 is something you should check out.