We’ve just done a quick test of a new 3D model repair tool, CUR3D Maker Edition.

The need for 3D model repair tools has never been higher, with the number of 3D printers increasing rapidly around the world. 3D printers and their software typically treat poorly formed 3D models in a bad way, often resulting in unpredictable print failures.

The root cause of most of the grief is simply the distressingly poor .STL file format standard, whose syntax permits the proper definition of 3D models that are not 3D printable. You can define non-solid 3D models with .STL, and unfortunately many 3D creation systems do just that when you export .STL files.

Thus the need for repair tools. There have been a few inexpensive and free options available, but more recently some of the action has moved to the cloud, where it isn’t always free. But there are still some reasonably priced standalone packages to be had.

One of them is CUR3D, made by Germany-based RUHRSOURCE, who seem to resell 3D printers as well. The company sells a “Maker Edition” for €50 (USD$58) and a “Full Functionality” version for €9,995 (USD$11,000). There are monthly and annual payment options as well.

CUR3D Maker Edition is designed to be extremely easy to use as it is designed for DIY makers, and it is. It does carry a very provocative billing, however:

CUR3D is the first real 3D printing prepress, making it the first software on the market to prepare a model of any size, no matter what scale, with any resolution for 3D printing.

I cannot believe this is a true statement, as there have been multiple 3D model preparation software options in the past. But let’s press on.

CUR3D Maker Edition has the most bizarre method of distribution I have ever encountered in years of 3D printing: it’s through Steam.

If you’re not familiar with Steam, it is a massive software distribution and management system focused on games. In Steam you can activate any number of games in your account, and have them delivered to whichever computer you’re using. Software updates are handled properly and you never lose your software license.

But it’s for games. Perhaps they were equating Makers with Gamers? That might be the case for some folks, but certainly not for most. I found it quite awkward.

Nevertheless, Steam is still a valid method of acquiring software, so we fired up our Steam account and activated CUR3D, which we were promptly met with this message:

Steam – Error

An error occurred while updating CUR3D Maker Edition (invalid platform)

What? Oh! We were running MacOS. Perhaps this is a Windows-only system? Yes, indeed it was, but this is not stated anywhere. We rebooted into Windows and (after installing Steam again) successfully launched CUR3D.

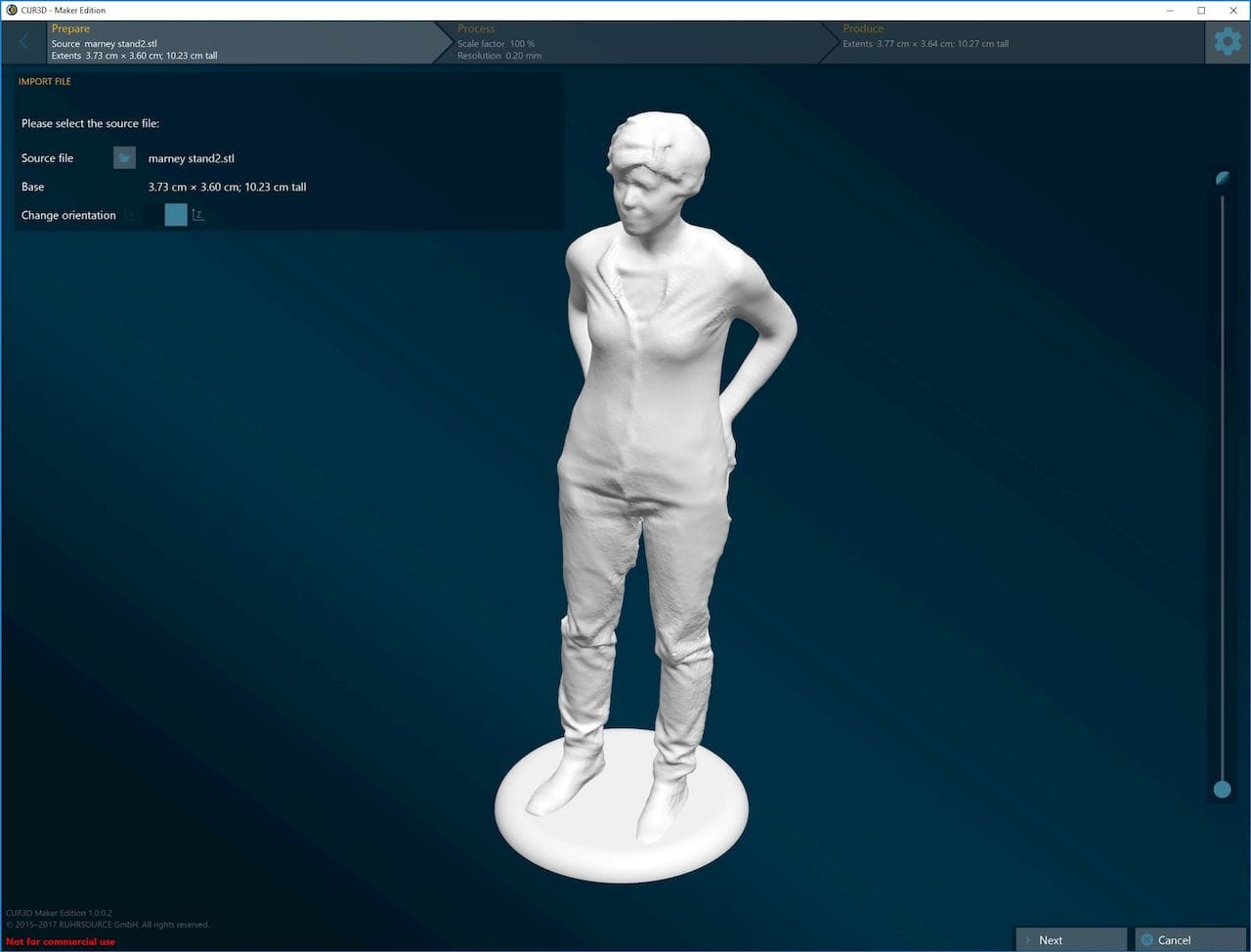

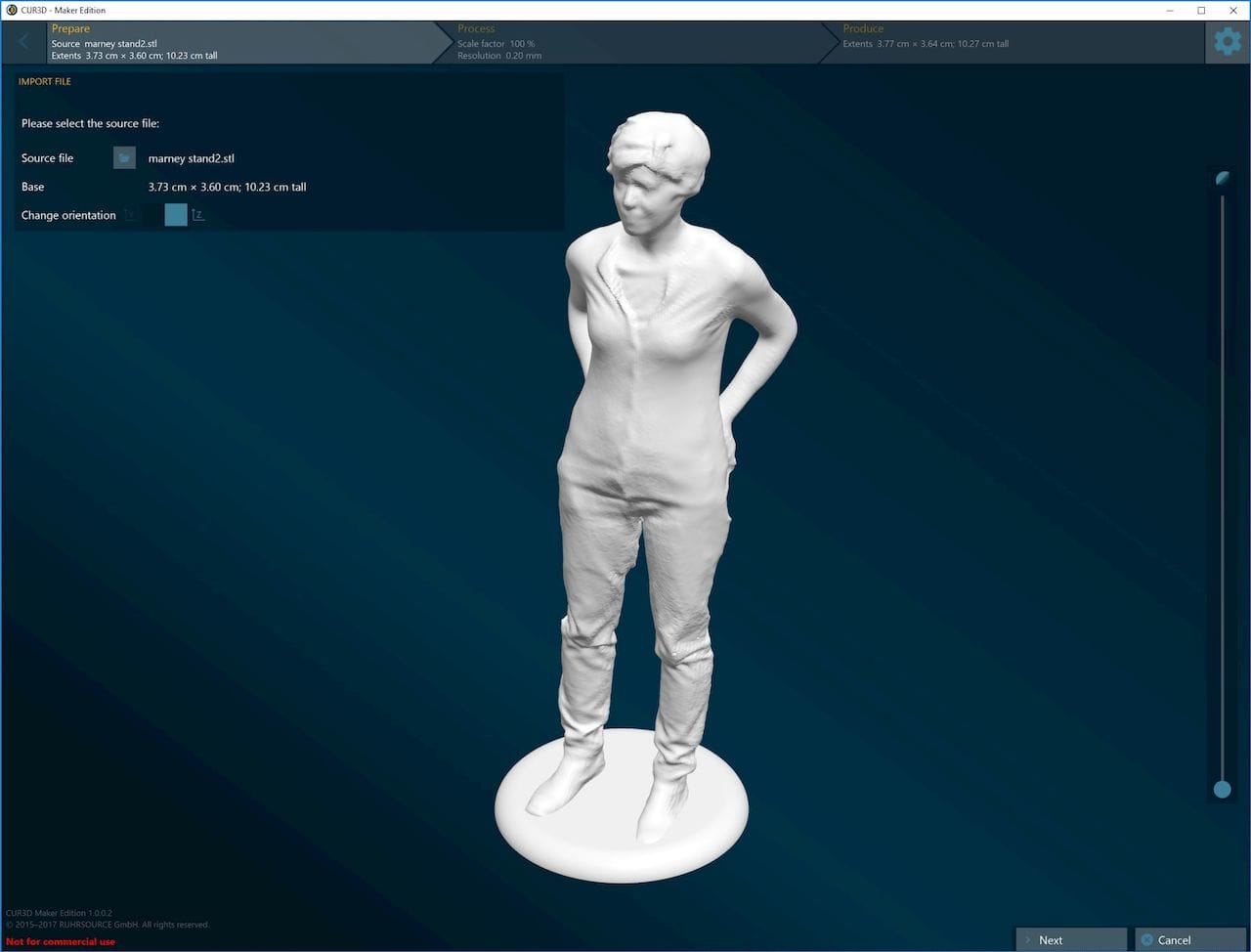

I have to say that the interface is ludicrously simple. There is simply nothing to do, other than select the file, pick a “Resolution” and hit “Proceed”.

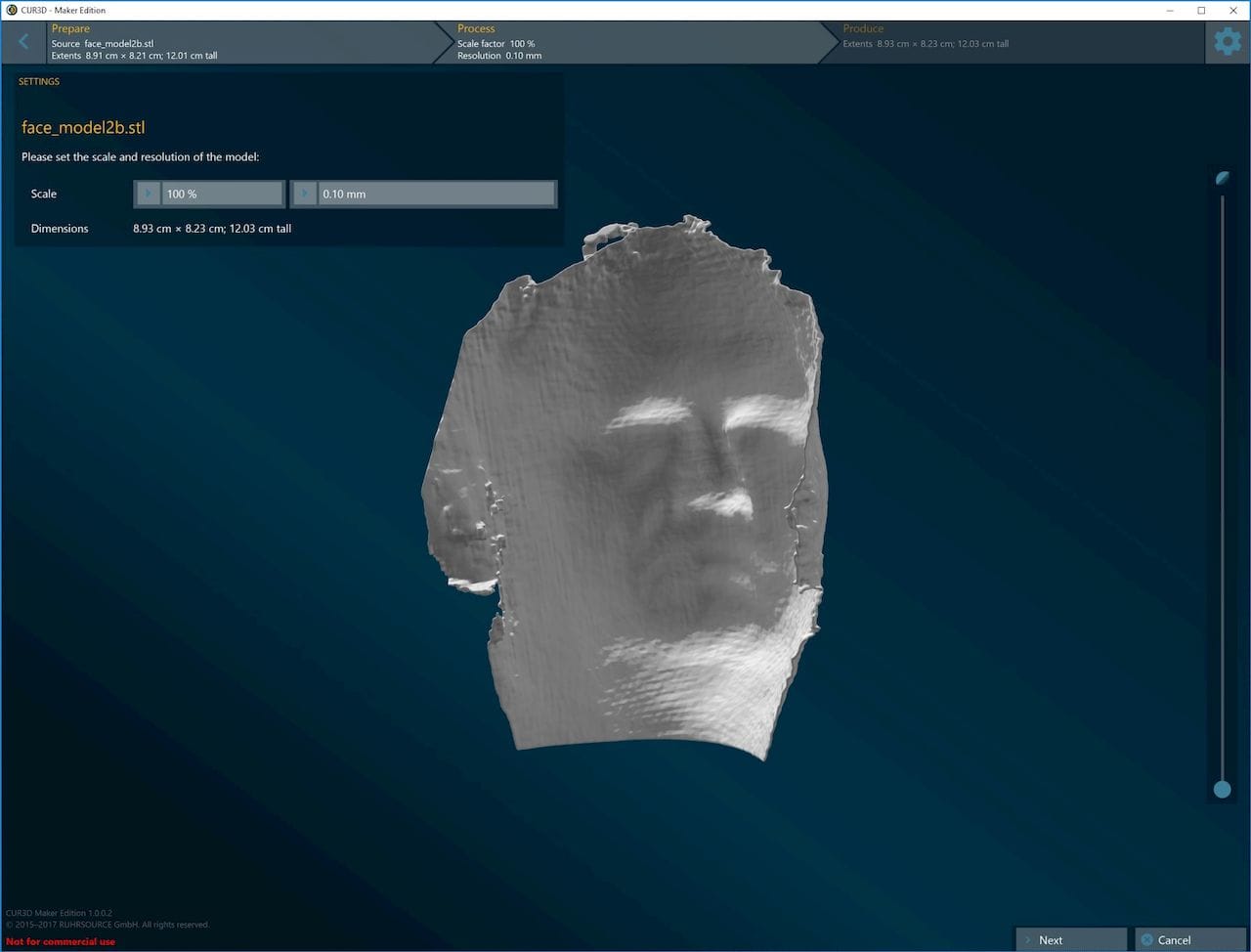

What is this “Resolution”? It’s not really explained, but I suspect that the software uses it as a kind of layer size through which it inspects the 3D model. Your resulting file is then “cropped” to that resolution, so I’d be careful if you have a 3D model with particularly precise structures.

And then you export the result. There’s not much else to it.

We tested a couple of different 3D models in varying states of correctness, and CUR3D seemed to fix them. It seems best at identifying redundant inner structures and eliminating them, which is helpful. One particularly pathological 3D model we tested, which was unresolvable by other tools at our disposal, actually was 3D printable after treatment by CUR3D.

However, all files we tested seemed to grow very significantly in size once through CUR3D Maker Edition, on average about 10X larger. This could be significant if your slicing program chokes on large sized 3D models. The full version of CUR3D apparently handles gigabyte sized files, so perhaps they aren’t so concerned at that level. But it could be significant at the maker level.

It is very unclear what exactly is being fixed, as you just press a couple of buttons. If you look at their web page, however, you can get a list of what is apparently going on behind the scenes:

- Automatic scaling

- Automatic thickening of walls

- Automatic correction of overlapping areas

- Automatic correction of wrong normals

- Automatic filling of gaps

- Automatic adjustment to the print bed

- Any 3D printer

- Any resolution

- Cut slider

- Wall thickness analyse

- Batch processing

- Explorer 3D model preview extension

Some of these features are clearly only available in the full function version, such as batch processing and “any 3D printer”. There is no way to specify a 3D printer in the Maker Edition.

What is not helpful is the distribution through Steam. The company insists that they are simplifying your workflow. Perhaps that is the case with the full edition, but it is not true with the Maker Edition, as you must fire up Steam before you can even load CUR3D. That’s a big extra step, for which you require security credentials and may suffer delays from updates, etc. It would have been much easier for users if it was distributed in a normal manner.

There may be other options for DIY 3D model repair, but I might suggest you could add CUR3D as another repair tool, since most 3D model repair services can fail on peculiar geometries and it is always a good idea to have more options.

For the full version, which we have not tested, I suggest you do a very thorough examination through a full trial to determine if the product is for you, simply due to the rather high cost of the tool.

Via RUHRSOURCE