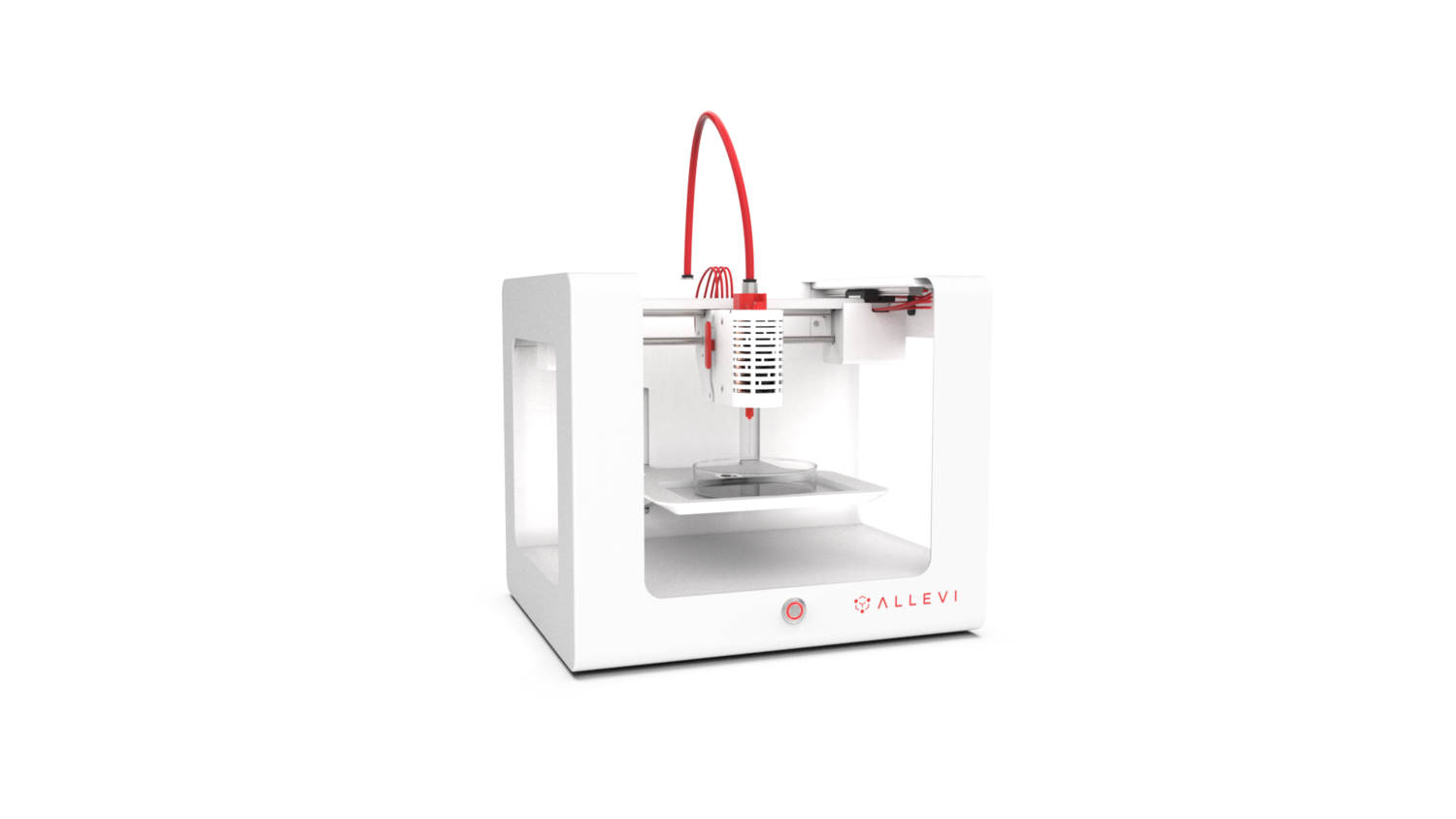

![The Allevi 1 Bioprinter [Image: Allevi]](https://fabbaloo.com/wp-content/uploads/2020/05/allevi1_img_5eb0a87deb1bb.png)

While bioprinting for many years seemed a far-flung bit of science fiction, companies like Allevi are seeing the 3D printing of live cells as a reality today.

Using living cells as a printable material is enabling significant advances in tissue engineering, pharmaceutical and cosmetic testing, tissue reconstruction and regrowth, and a future that seems to indicate that full, transplantable 3D printed organs is an inevitability, not a B-movie subplot. From the materials used to the systems laying the layers to the laboratory environment, each stage in the bioprinting process must be carefully considered – and that R&D is leading to present-day and near-future strides forward.

I caught up with Ricky Solorzano, the CEO of Philadelphia-based Allevi Inc., to hear more about the company’s work in the bioprinting space.

![Ricky Solorzano, CEO, Allevi [Image: Allevi]](https://fabbaloo.com/wp-content/uploads/2020/05/ricky_img_5eb0a87e9fc29.jpg)

Can you provide a bit of background on your career and what led to the genesis of Allevi?

“I studied bioengineering in college and while there worked at a tissue engineering lab doing vascularization work. Jordan Miller, built his own 3D printer to print sugar glass to make vessels in gels. Noticing that other companies were taking 3D printing desktop in different industries, SLA, Carbon Fiber, Plastic, I begged the question if we did it with bioprinting would there be a market? 1 year later we launched the Allevi 2 and started having customer requests from all over the world.”

What is Allevi’s mission statement? How has this evolved over the last few years?

“Allevi’s mission is to empower others to design, engineer, and create 3D tissues. How we can help our users execute their vision of a specific tissues or easily access an already premade design. I believe we have been pretty consistent about our mission — what has definitely evolved is the breadth of our end users. We really started with just material scientists, then moved to tissue engineers, and now are moving into biologists.”

What applications do you see as being a good fit for bioprinting solutions?

“At the heart of what bioprinters do is to add geometry to biology.

A few key areas have arisen as great value adds to users in biology:

- Thin layers

- Vessels in Gels, as Jordan Miller first did, a new kit with Volumetric Bio, Jordan’s company, is coming soon!

- Hydrogel patterning.”

How is Allevi addressing these applications?

“We are realizing the need to switch from providing an offering for just the platform, to an offering of applications that allows users to simply bring their own cells to begin to allow biologists to contribute to the world of bioprinting.”

How does Allevi approach biomaterials development?

“We look to the community! Biomaterial development is definitely one of the key components and understanding how the material science community tackles controlling biology has been at the heart of how we navigate what biomaterials to use and provide to our user group.”

What sets the company’s offerings apart as the bioprinting market grows?

“We focus on the platform, and I think we are pretty close to being the best platform out there. We love making things easy for our users, but at the same time packing in a ton of power into our systems to provide versatility. So whether your developing something cutting edge or a biologist trying to easily replicate a tissue, no one else is so obsessed about the platform and how it empowers others.”

What impact do you realistically expect to see bioprinting have in the next year? Five years? Longer-term?

“Lots of science, a rising pharma presence, and some possible implants. I think the science communities will continue to ask novel questions and add geometry to biology to replicate the body more accurately outside the body. At the same time as applications arise, killer apps per se, we will begin to see those being applied to problems within industry trying to study specific tissues, skin, tumors, and diffusion of drugs to name a few.

5 years I believe the total amount of ideas and solutions created by bioprinters will be exponential. Longer term I do believe we will see implants with a patient’s own cells.”

Do you foresee the 3D printing of functional organs for human use as a reality? When?

“Functional organs is a relative term, I think most people think when you make an organ for it to be valuable has to look like the natural one and do everything that the ones in our bodies do. The truth is that if a piece of tissue, even small, could even perform one function to provide some sort of output that could be extremely useful. That’s like 7 years.

I think we’ll start seeing deposited advanced materials that will promote regeneration even sooner. For example, our bone kit, with Dimension Inx (they’re awesome!), will allow orthopedic surgeons in the future to print a scaffold to a patient’s natural defect. While there are no cells the 3D printed construct will be implantable and promote natural bone regrowth.”

![[Image: Allevi]](https://fabbaloo.com/wp-content/uploads/2020/05/allevi_img_5eb0a87ef3b71.jpg)

What levels of regulation must be addressed at each step in the development process?

“The two key areas in the development process for bioprinting will be patient data and then quality control of the actual printed object. The quality control around the actual printed object is going to be something several discussions have to be organized for especially depending on the tissue.”

What else should we know about bioprinting? About Allevi?

“The age of applications is rising for bioprinters and it’s an exciting time. For Allevi, we invite everyone to check out our repository for bioprinting and applications at buildwithlife.com. And stay tuned as we continue to release tools that empower scientists to tackle some of medicine’s most challenging problems.”

Via Allevi

FELIXprinters has released a new bioprinter, the FELIX BIOprinter, which is quite a change for the long-time 3D printer manufacturer.