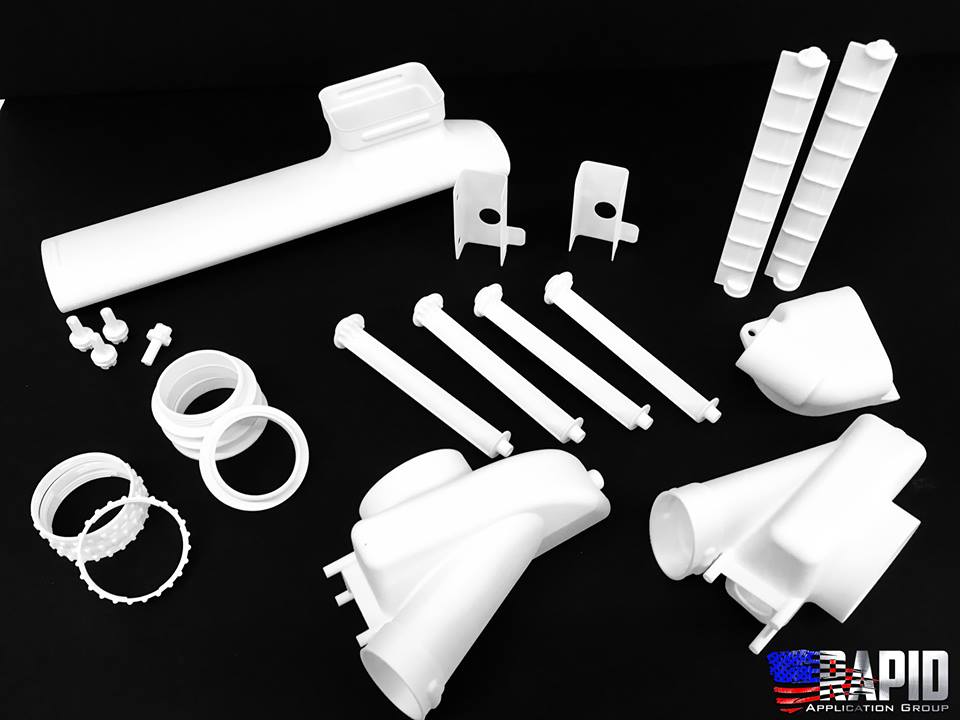

![[Image: RAG via Facebook]](https://fabbaloo.com/wp-content/uploads/2020/05/RAG_img_5eb0a63908a67.jpg)

Rapid Application Group exemplifies the localization and democratization that 3D printing so often touts as a benefit.

The Oklahoma-based company is a service-disabled veteran-owned small business, offering engineering and advanced manufacturing services — all centered around additive manufacturing. Taking cues from his time in the US Army, Founder and CEO Terry Hill set his sights toward this entrepreneurial endeavor that offers mission-critical parts production and prototyping, working with customers and the community.

In addition to offering manufacturing services, Rapid Application Group (RAG) works with veterans to train them in additive manufacturing (AM) as a workforce initiative. The veteran hiring initiative helps those transitioning to civilian employment, taking skills learned in the armed services and translating them into advanced manufacturing.

I caught up with Hill recently to discuss RAG’s operations and the entrepreneurial and manufacturing capabilities offered via 3D printing.

![Terry Hill, Founder and CEO, RAG - and Jonsie [Image: RAG]](https://fabbaloo.com/wp-content/uploads/2020/05/Terry-and-Jonsie-3_img_5eb0a639acdaa.jpg)

How did your experience as a disabled veteran lead to founding your own company?

“I spent 13 years in the Army as an Engineer and Medical Evacuation Pilot/Maintenance Test Pilot and Research Pilot. My last duty station in the Army was as a Research Pilot at the United States Army Aeromedical Research Laboratory at Ft. Rucker, Alabama. During my time there, I invented a piece for our flight helmets named the Hill Helmet Mount and this was my first interaction with AM. The Military gives you every tool to be a successful entrepreneur. The Military teaches you loyalty, selfless service, to never quit and how to grind day in and day out. It doesn’t matter what rank you leave the Military with; the entrepreneurial foundation is the same.”

Why additive manufacturing?

“I immediately saw the benefits of AM while developing my helmet mount. After exiting the military due to injuries sustained in Afghanistan, I was the Director of Business Development for a publicly traded Aerospace Company. I could see that our group of companies could benefit from AM, I volunteered to program manage the implementation of AM and automation across the entire group of companies. The company I was a part of decided not to make the investment, so I resigned and started Rapid Application Group LLC.”

Can you share details about your veteran hiring program to train in AM skills?

“We have structured a training pipeline that is similar to the training program that I went through as a US Army Aviator. This is a standardized process that pilots go through when arriving to their first duty station. When Veterans arrive, we start out with the basics of AM. Terminology, basics of AM, etc.. then we move into FDM, SLS, SLA then DMLS. It is structured in a way that everyone that comes through understands the same information and has been tested before moving on to the next section.”

How do you see 3D printing helping veterans looking to (re)join the civilian workforce?

“As a Certified Service-Disabled Veteran-Owned Small Business, I can attest that 3D printing is a great resource for Veterans exiting the Military. There are AM classes being offered now that will allow more of a smooth transition in to the civilian sector. As Veterans, we are used to a process and procedure-based environment and AM provides this structure.”

What are your views on the importance of AM in today’s work environments?

“AM is critical to those who have an open mind to adapt to the technology. I have toured many companies that could absolutely benefit from AM, but due to the ‘we have always done it this way’ mentality, they fail to adopt the technology. I try to explain that AM will never completely replace the CNC machine, but rather AM opens up capacity for those machines.”

What technologies are you working with via RAG?

“We run SLS, SLA, FDM, DMLS and MJP.”

What are your hopes for the next year with RAG? The next five years?

“A hope is a dream without a plan. In the fall of 2018 we will finalize our AS9100D/ISO9001 certificate and we just received our ITAR certification as well. Our plan for 2018-2019 will be to continue to grow and purchase/build the most state-of-the-art facility in Oklahoma. We are growing at a rate that is one of the fastest growing companies in Oklahoma and we want to maintain the momentum as our customer base rivals that of the large AM service bureau. Our 5-year plan involves the acquisition of more SLS, SLA, FDM,DMLS machines and hiring 10-15 more Veterans.”

![[Image: RAG]](https://fabbaloo.com/wp-content/uploads/2020/05/Rapid-Application-Logo-Header-with-COPY-NEW_img_5eb0a63a3b1ae.png)

What else should we know about your work with RAG, 3D printing, and veterans?

“RAG has grown at an unbelievable rate and it is all due to the hard work and dedication of our team. Our motto is ‘We Provide Time Sensitive and Mission Critical Support Though Additive Manufacturing’ and we take this seriously.”

Elizabeth C. Engele (Lizzy) is a designer for social good, and a founder of MakerGirl.