We caught up with Pete Basiliere, Research Vice President, Additive Manufacturing at Gartner for a look at predictions in 3D printing and 4D printing in 2019.

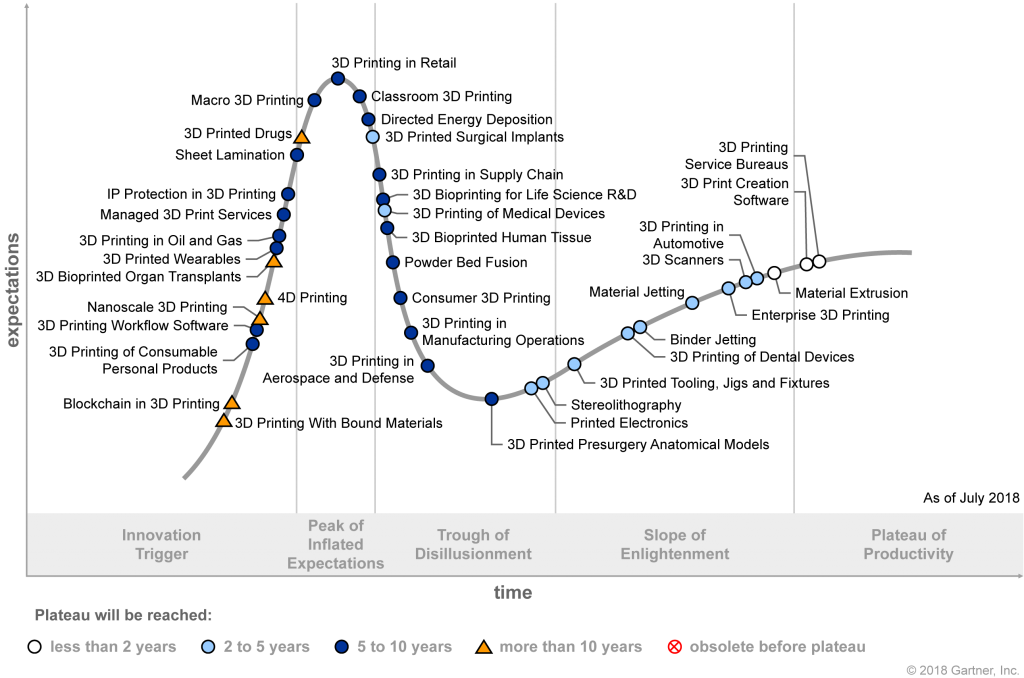

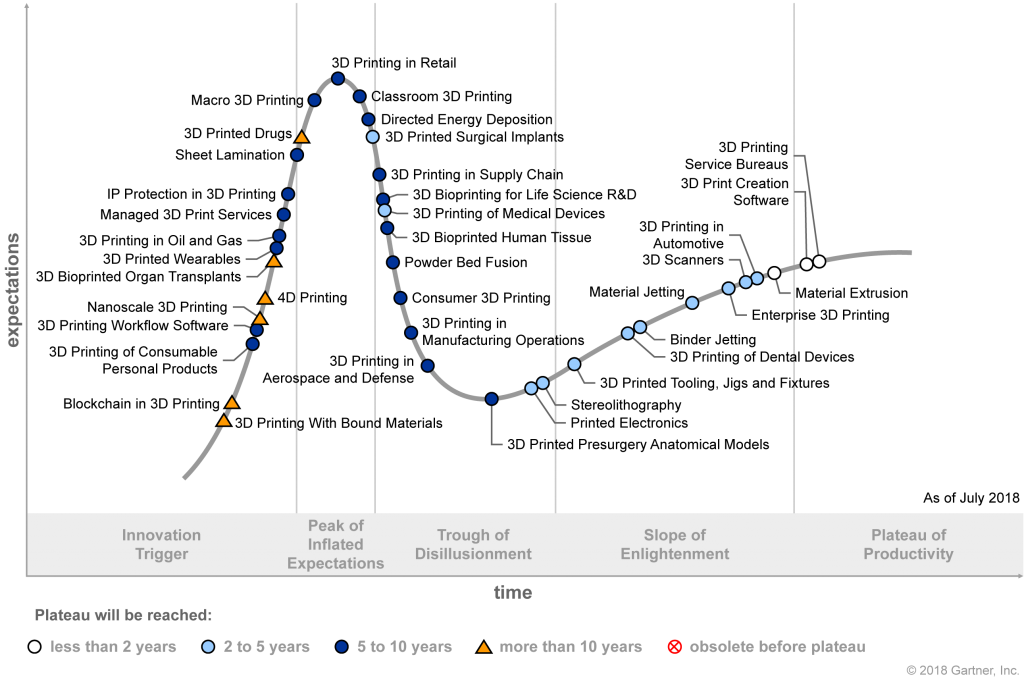

Gartner is best known in 3D printing for its iconic Hype Cycle, which tracks developments on their progress toward the ‘plateau of productivity.’ The Hype Cycle was recently updated to cover 2018, and the research and advisory firm is already looking ahead in this new year.

Basiliere, a leading expert on additive manufacturing, published a blog about Gartner’s predictions. Titled “3D Printing Accelerates, 4D Printing Gets Started” (as is the full Gartner report) his piece points to key trends and themes to watch.

Venture capital for 4D printing, a rise in 3D printed medical devices, biosynthetics, wearables, and metal additive manufacturing take the stage in Basiliere’s look.

It’s always a pleasure to pick Pete’s brain, so I turned to him with a few questions for a closer look at a new year in 3D printing. It’s interesting to compare his responses this year to the conversation we had with him last year following the 2018 predictions.

What do you feel are some of the most poignant trends in 3D (and 4D) printing as 2019 begins?

“‘Poignant’ is an interesting choice of words. I wouldn’t say that any of the predictions are poignant.

Practical uses of 3D printed items continue to expand, with significant growth in the medical device and wearables markets. A critical factor in accelerating adoption will be the ability for healthcare regulation to keep up with the opportunity across geographic regions.

Worldwide, almost 200 manufacturers produce enterprise-class 3D printers costing from $2,500 to several million dollars. The number of providers has more than doubled over the past three years, the result of research and investments by public and private institutions worldwide. While Gartner does not count their numbers, materials providers that formerly focused on conventional manufacturing are now also providing powders, filaments and resins for use in 3D printers.”

Metal 3D printing was a major theme in 2018; what can we expect this year? Which metal technologies are seeing the most productive applications?

“The goal for many organizations is 3D printed metal parts, whether a component of a larger product or as the finished, saleable item. 3D printing small volumes of these pure metal or metal alloy parts is particularly attractive in markets such as aircraft, spacecraft, watercraft and undersea craft, as well as cars and trucks, military equipment, medical devices, and manufacturing systems.

3D printers that use bound materials will further accelerate the trend to lower ASPs and increased shipments. 3D printing with bound materials is an additive manufacturing process used to produce items from a powder that has been dispersed within a carrier material or joined by a binding agent. Drawing on traditional metal injection molding (MIM) and ceramic injection molding (CIM) techniques, 3D printing with bound materials is a new additive manufacturing process that is based on proven conventional production technology. The process is a low-cost alternative to traditional metal and ceramic additive manufacturing technologies and can be used in a potentially wide range of applications.”

Bioprinting and 4D printing stand out in your predictions blog; what makes these areas worth watching (or not) in the near term?

“3D printing prosthetic limbs and appendages (for example, ears) and some specific internal valves is progressing rapidly, primarily using various polymers as the material. During the past three years, the rapid development of bioinks and specialized print heads and nozzles for 3D printing stem cells, coupled with improved multicartridge capabilities, has enabled significant advances in hybrid ‘biosynthetic’ structures.

4DP is an opportunity to create future technology-based products that could disrupt industries. Shape-shifting materials have already been leveraged on a small scale in the automotive, aerospace, defense and medical industries. Initially, the examples of ‘what’s possible’ will be technology-focused. Understanding the business opportunities and revenue impacts will take longer.”

What else should we be thinking about in terms of adoption and progress?

“Recommendations:

Determine the innovation trends that may impact your business by monitoring venture capital investments in startup 3D printer technology, modeling software and materials providers.

Scan your market and adjacent industries to discern how competitors employ 3D printing.

Although 4D printing technology is still embryonic, build 4D printing into long-term technology development roadmaps.”

In mid-December, Gartner published annual predictions for the 3D printing industry in a detailed 20-page report. Co-authors included Basiliere, Ivar Berntz, Miriam Burt, Anshul Gupta, Mike Jones, Dale Kutnick, Marc Halpern, and Michael Shanler.

Via Gartner

1 comment

Comments are closed.