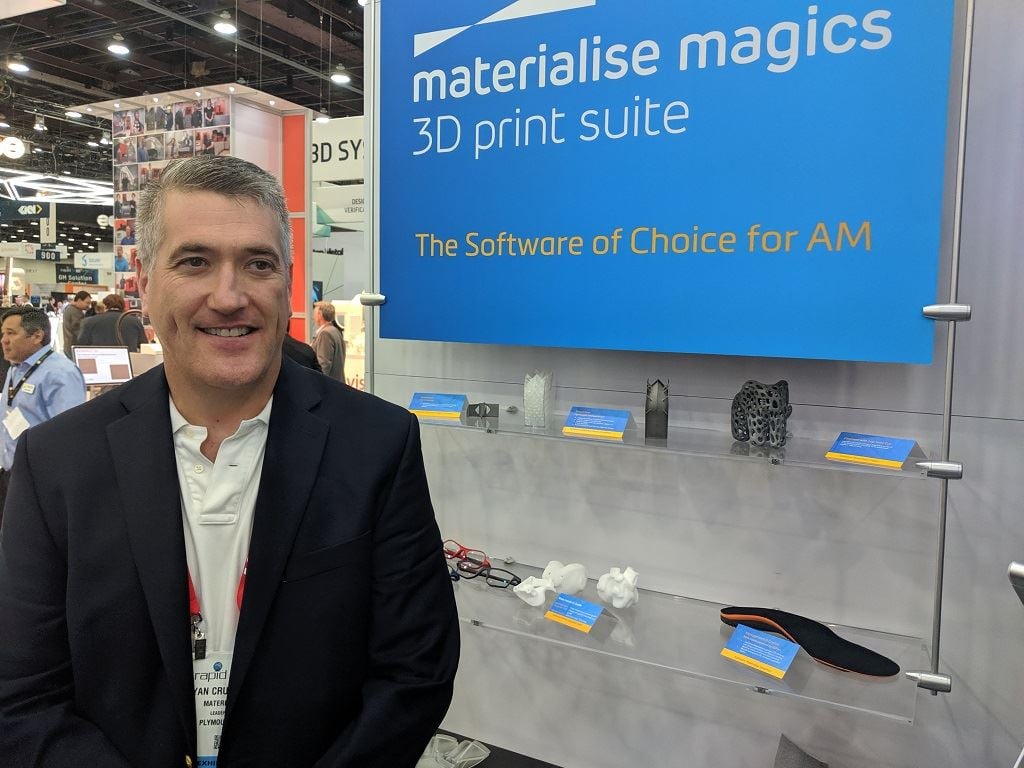

![Bryan discusses software, collaboration, and smoother workflow [Image: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/Materialisepartnerships1a_img_5eb09671a2aed.jpg)

Saying “Materialise focuses on collaboration” is a bit like saying “rain is wet” these days, but the prolific company continues its deluge of co-creation announcements.

Materialise has so many partnerships these days that every so often I look around and wonder if I’m working with them, too. I’m not, but it seems just about every company I talk with is a Materialise partner. The company announced several more collaborative relationships during the recent RAPID + TCT, and as expected, these are just the tips of more icebergs.

Bryan Crutchfield, Vice President and General Manager, Materialise North America, noted that Materialise is “consistent with its message of collaboration.” Yes, yes they are. He filled me in on the thinking behind several of the newest collaborations and more steps forward in software to streamline the additive manufacturing workflow.

The company has deepened its collaboration with HP and introduced more detail on partnerships with Nikon and Essentium. Materialise will also be releasing Streamics 8, its 3D printing operations management software, this month.

“For everyone who has printers, we want to unlock a seamless workflow,” Crutchfield said. “Co-creation involves work with large manufacturers to help them to understand 3D printing in their workflow and drive more meaningful relationships.”

Software

These meaningful relationships are, from Materialise’s perspective, encouraged by functional and user-friendly software.

Software is integral to a smooth workflow, and Materialise is consistent with its focus on productivity and connectivity. Streamics 8 in particular is dedicated to “better connectivity with the industrial factory floor,” the company says.

This release also makes MTConnect standard as a compliant build processor to connect with more machines, Crutchfield noted, with some of Stratasys’ 3D printers among them. This he, said, “enables a whole new ecosystems of machines to connect.”

Streamics 8 offers a fully configurable web portal, enabling design and production floor staffs to work together better. Build preparation is also made more efficient through new features such as automatic nesting across multiple build platforms. Machine monitoring for Arcam and HP 3D printers is also offered with dedicated build processors, enabling live monitoring of machine parameters.

As well as Streamics 8, Materialise is introducing Simulation 2.0, the next version of its simulation software. Available as an optional module with Magics 23, the simulation software includes new features like ‘part compensation’ and a way to simulate heat diffusion, as well as speed improvements for file management.

Collaborations

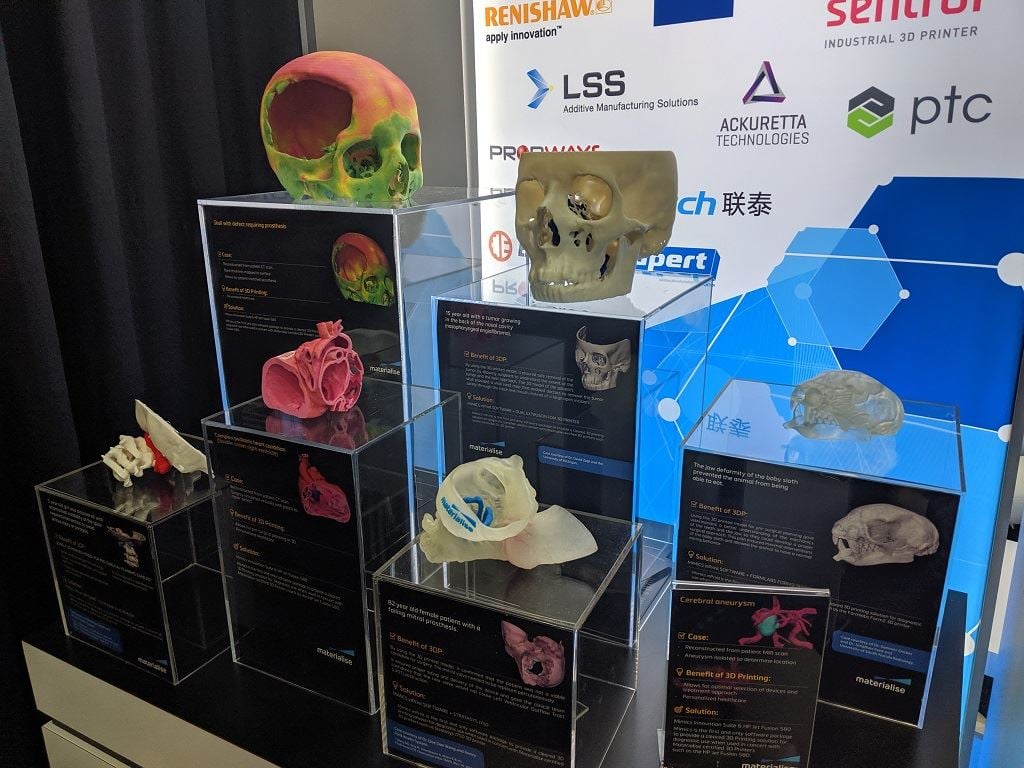

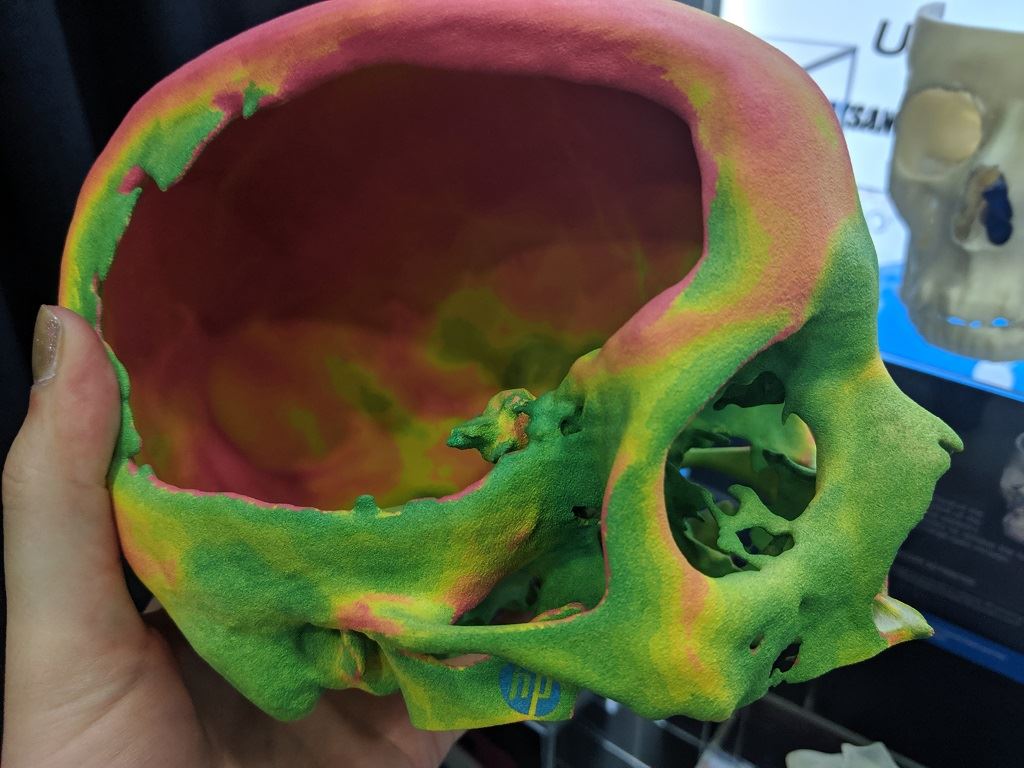

Medical models made with Materialise software: focus on HP 500/300 series model [Images: Fabbaloo]

With HP, Materialise is expanding collaboration to develop a new version of its build processor to include the newer Jet Fusion 5200 and Jet Fusion 500/300 Series of Multi Jet Fusion offerings. This Materialise HP Build Processor 2.0 is set for availability in H2 2019. The offering will “help users to use HP equipment and lead them down the path to better 3D printing,” Crutchfield said. Part of that path includes access to Materialise Magics Essentials for six months following the purchase of a Jet Fusion 500/300 system.

Further, HP joins Stratasys, Formlabs, and Ultimaker as systems validated for Materialise’s FDA clearance for 3D printing anatomical models. Medical 3D printing work remains important to Materialise, as Crutchfield noted that the team is continuing collaborations with Henry Ford Health System and others turning to more 3D printing for diagnostic and planning purposes.

Looking to the Nikon announcement, Materialise is aiming to “improve insight into the 3D printing build process,” allowing users more control and productivity.

With Essentium, Materialise is building on the strategic partnership announced in November. Focus here is on scaling industrial 3D printing, as Materialise integrates its Magics Essentials software with Essentium’s HSE (High Speed Extrusion) 3D printing platform.

Collaborative Spirit

“Materialise is sitting in a unique place in the ecosystem,” Crutchfield said. “We work with Siemens on the creation side, with OEMs like HP, Nikon, and Essentium, and these are all folk with software needs. On the medical side, image-based anatomy work is better serving customers and patients with custom care. This all allows us to do more unique networking. We always say we can’t do it alone.”

If you’re ever at a Materialise event and need a ‘free’ space for your bingo card, go ahead and put “collaboration” or “co-creation” there as a box you know will be ticked. And that’s very intentional: “Collaboration is our DNA,” Crutchfield said, “It’s how we’ve survived the last 29 years.”

To his point, he’s quite right that Materialise can’t do it alone; no one entity can. No one technology can. And so casting a wide net, working with a vast variety of partners and gathering different approaches, different ways of thinking, together, is helping industry overall to evolve.

And, as something of a warning, that mentality goes both ways:

“You can see the companies that are closed are the ones that are struggling,” Crutchfield noted. “Look at Betamax and the VHS standard.”

Industry 4.0 is rapidly emerging as the integrated future of industry. Just as additive manufacturing is a part of that, but not nearly the whole story, so too is each company working together to make additive manufacturing a viable component to Industry 4.0.

There’s certainly something worth paying attention to from Materialise, as their strategies are working out for them pretty demonstrably.

“Collaboration is what will make it evolve,” Crutchfield said.

Via Materialise