![[Image: 3D Hubs]](https://www.fabbaloo.com/wp-content/uploads/2020/05/3dprinting1_img_5eafb3da22ed0.jpg) [Image: 3D Hubs]

[Image: 3D Hubs]

SPONSORED CONTENT

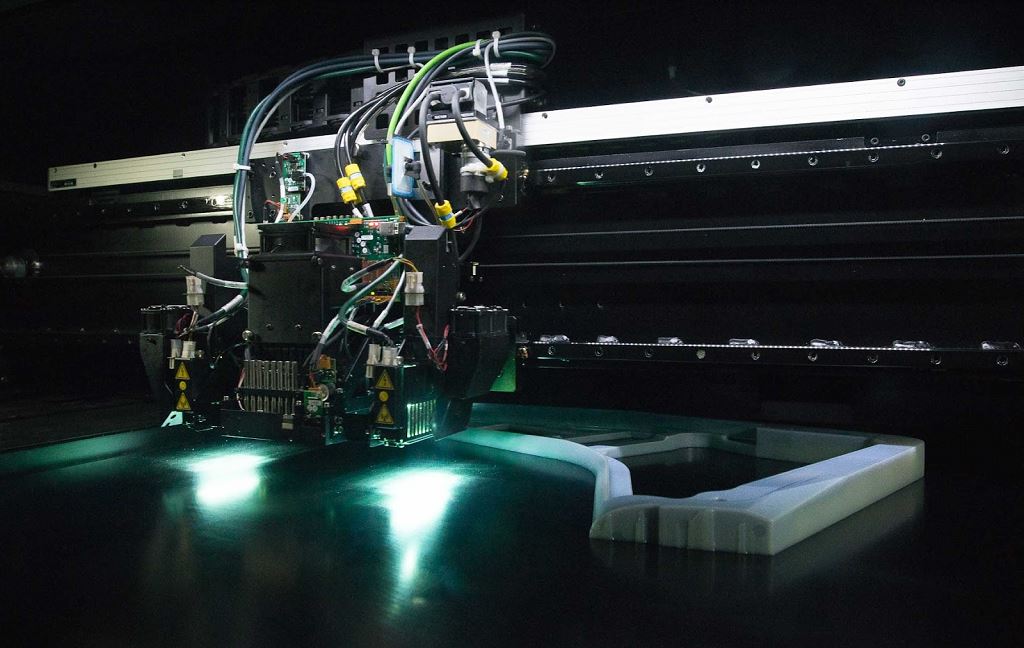

3D printing can be used to make amazing sculptures and innovative technology — but do you know how a 3D printer actually works? A good understanding of the manufacturing process will make it easier to design your own creations.

3D Printing Is an Additive Manufacturing Process

3D printing is actually quite similar to regular printing processes. A normal printer places a layer of ink on paper. If you were to run the same document through a printer many times, you would eventually get an extremely thick layer of ink.

Instead of ink, a 3D printer uses plastic, polymer, or metal to build an object out of multiple layers. This is an additive manufacturing process. Each layer adds complexity and builds on the foundations created by previous layers.

In comparison, CNC machining is a subtractive manufacturing process. CNC manufacturing is similar to wood carving or lathing; material is cut away from a block of wood or a metal rod until it resembles the desired object.

At 3D Hubs, we can connect you with both printing and machining services. Whether to use an additive or subtractive process depends on the object you would like to create.

3D Printing Processes: The Terms You Need to Know

![[Image: 3D Hubs]](https://www.fabbaloo.com/wp-content/uploads/2020/05/3dprintmodels1_img_5eafb3da529fa.jpg) [Image: 3D Hubs]

[Image: 3D Hubs]

There are seven standardized forms of 3D printing. We’ve published a complete guide to each of these processes and the materials they work best with. You don’t need to memorize all of them, but you should understand the basic technologies that make 3D printing a reality.

Extrusion

-

Extrusion — Extrusion is the process of melting material and piping it through a nozzle. Fusion deposition modeling, or FDM, is an extrusion-based process that uses spools of polyester, nylon, ABS, and other common 3D printing materials.

Curing

-

Curing — When a 3D printed object is made from resin, the object always starts out as a vat of liquid. Lasers are used to cure and harden layers of resin until the desired shape is achieved.

Jetting

-

Jetting — Jetting printers “spray” layers of particles to create a three-dimensional shape. Material jetting is quite similar to normal inkjet printing. Binder jetting alternates layers of material and adhesive to create a finished product.

Fusion

-

Fusion — Most 3D printing processes rely on some sort of fusion to bind particles. Metals and plastics are heated and solidified to create an object. Some of these processes lay the particles in a specific shape; other processes selectively fuse particles from within a vat of polymer powder.

Using a 3D Printing Service

![[Image: 3D Hubs]](https://www.fabbaloo.com/wp-content/uploads/2020/05/3dprinter1_img_5eafb3da88397.jpg) [Image: 3D Hubs]

[Image: 3D Hubs]

To use a 3D printing service, you will need a CAD model of the object you want to print. 3D printing programs “slice” this digital model and determine the order in which layers should be created. We recommend that you keep the limits of your chosen manufacturing process in mind while you design your model.

Once you have a model that you like, upload it to a 3D printing service. You’ll be asked to select a material and a manufacturing process. When you use 3D Hubs, you’ll get an instant quote based on the specifics of your digital design.

As soon as the manufacturer has your final design, they can begin work on your product in a matter of minutes. Some objects may require post-processing to reach a finished stage.