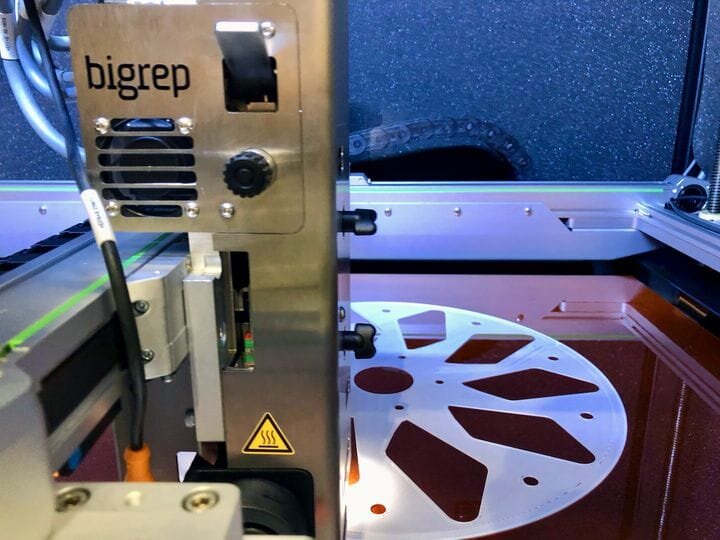

![The BigRep Studio G2 3D printer [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08c98891a1.jpg)

It seems that BigRep is on a bit of an ecological path these days.

I had a chat with BigRep executives about the latest happenings at the Berlin-based manufacturer of large-format 3D printers, and heard of some important tweaks to their G2 Studio system. It also sounds like they will enter the high temperature 3D printing market some time next year, and we’ll cover that when it happens.

But what was more interesting was their thoughts on eco-friendly products, and by that I mean 3D printable materials and associated processes.

BigRep Pro HT Filament

For some time now they’ve marketed their Pro HT general-purpose polymer for their equipment, but it is less known that this material has a significantly good eco-profile. They say:

“As a material derived from organic compounds, Pro HT is biodegradable under the correct conditions. CO2 neutral and environmentally friendly, it has a much lower ecological impact than other plastics derived from fossil fuels.

Pro HT is FDA compliant for food safety and meets all requirements of EU Directives on food contact.”

Industry Needs More Eco-Friendly 3D Printer Materials

What BigRep has discovered is a need by industry for eco-friendly products. One application they’ve seen is the requirement for biodegradable molds. If you think about it, some of BigRep’s clients will be producing large, custom-made end-use products by casting material into huge 3D printed molds. After the casting is done, then the molds are discarded.

![Huge concrete formworks made on the BigRep Studio G2 3D printer [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08c98b3ede.jpg)

But wait, those polymer molds would simply sit in the environment for years, shedding microplastics. A client in that business would soon accumulate a huge pile of large, used casting molds. That’s not good.

BigRep says they’ve now seen a push for bio-friendly materials and also recycling. Currently, BigRep is working on recycling solutions for their clients, but has not yet announced anything specific.

Is this need for eco-friendly products for real? It seems so, as BigRep says Ford, yes, the automotive giant, switched to BigReps’s products partly because of their need for reusable materials.

3D Printing Eco Trends

![A BigRep Studio G2 3D printing some large pieces [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08c98da88f.jpg)

As I’ve mentioned previously, it seems there is growing interest in eco-friendly products and services by at least some manufacturers, and I suspect this trend is going to increase as time passes.

The message for 3D printer manufacturers and material providers is that there should be made available products and services to facilitate eco-friendly practices. This will mean bio-compatible materials that can be recycled or properly degrade on their own. It also means the 3D printers themselves must be able to use such materials to produce quality parts, perhaps through the use of eco-friendly print profiles.

Are 3D printer manufacturers doing this? In my explorations it seems that several are indeed moving in this direction, but the majority still do not recognize this as a trend.

But they will.

Via BigRep