Photocentric is undergoing a transformation, as many 3D printer manufacturers are doing these days.

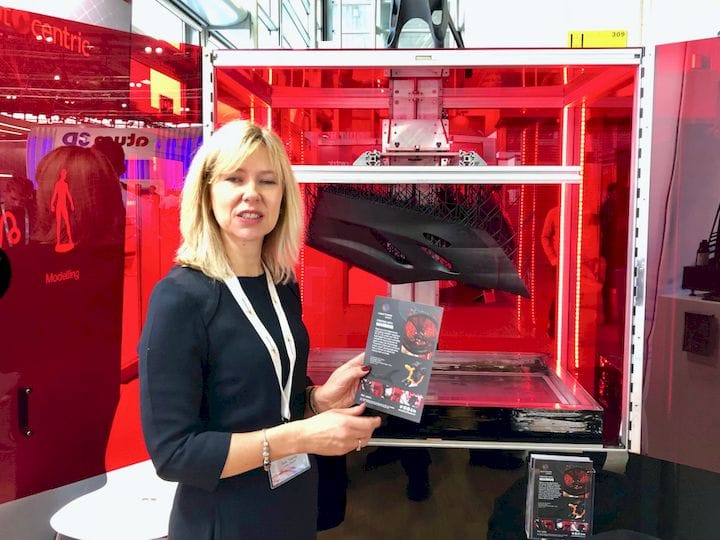

I recently spoke with Sally Tipping of Photocentric to find out the latest developments in the UK-based company’s journey, which we’ve been following closely over the past few weeks. Most recently they had developed a method of 3D printing an astonishing number of PPE parts per week on their equipment.

Photocentric During Isolation

Like most companies, Photocentric has had to change their internal work practices due to stay-at-home orders. Yet, even though almost all of their staff work from home, they are still manufacturing. In this case, they are producing PPE items (face shields), to the tune of 7,000 per day. However, Tipping says the rate is slowing a bit to correspond with virus spread slowdown.

Photocentric has furloughed around 25 staff, but has already been calling them back for reasons I’ll explain below.

Their experience during the emergency has been quite interesting and indeed transformative. In the process of producing so many PPE parts on their 15 large printers all day long, they have become a user of their own equipment to a very deep level. While they build their large-format SLA 3D printers, they don’t normally operate them to this degree.

The experience has revealed to them much about their equipment and how it can be made even better in the future. Tipping said:

“We can see what the printers are actually capable of.”

Tipping says they have been “living the life of their clients”, and thus have learned a great deal about equipment use. For example, “how often do you really have to change the film”, and other “little things” that are, in total, quite important.

And the main revelation is that the devices can indeed be used for end-use part manufacturing. While normal supply chains were broken, their equipment was able to be set up very quickly to produce high volumes of parts. Other traditional manufacturers were unable to do this.

Photocentric Transformation

I asked Tipping whether they’ve seen a change in orders due to the ongoing crisis, and she had a very intriguing answer.

Orders from their normal set of clients dried up, as they usually sell equipment to the dentistry industry. As dental operations are effectively closed worldwide, there’s not a lot of orders, at least for now.

However, Photocentric quickly saw these clients replaced with a new set of customers. These were organizations seeking ways to quickly manufacture parts using 3D printers, including medical organizations. Tipping says their business is suddenly back to normal levels, but with different clients.

When the crisis abates, she feels Photocentric will have more clients than ever before: their existing clients, plus the new ones that emerged during the emergency.

Photocentric Resin Availability

Photocentric not only produces large-format SLA 3D printers, but also is one of the world’s largest producers of photopolymer resin. In fact, that was their original line of business. I asked Tipping whether they’ve had troubles in that business due to the crisis.

Tipping explained they’ve not seen any problems with their supply chain for base chemicals and have been able to produce as much resin as required, saying there have been “no issues.”

What was interesting, however, is that they are making more resin than they’ve ever done in their history, with March being their biggest production month ever.

Since Photocentric is the white-label provider of 3D printer photopolymer resin for a number of third party and manufacturer’s brands, this strongly suggests that those using resin 3D printers worldwide are quite busy these days.

That’s not surprising, given the utility of 3D printing technology during the emergency.

Via Photocentric