The 3MF Consortium is looking ahead to more adoption in 3D printing, now operating as a Linux Foundation member and with a new executive director.

The 3MF days of development are behind us; the new file format, first dreamed up five years ago in a Microsoft-led consortium of big names, is freely available for use, solving many of the issues of other 3D printing file formats. Now, new 3MF Consortium Executive Director Luis Baldez tells us, the focus is on adoption.

3MF Consortium

In 2015, the 3MF Consortium emerged, led by Microsoft and including among founding members Autodesk, Dassault Systèmes, NetFabb, Shapeways, HP, and SLM Solutions. Membership has grown since, notably including Materialise, EOS, 3D Systems, Stratasys, Siemens, GE, Additive Industries, nTopology, and many others as both Founding Members and Associate Members.

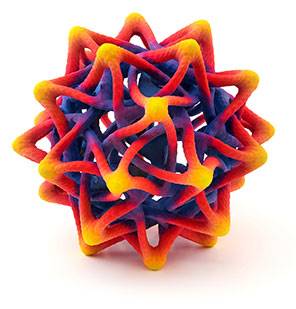

The overarching goal was — and is — to supplant other, inferior 3D printing file formats. Let’s be honest, no one really likes working with .stl files, especially for more complex 3D printing projects involving lattices, multiple colors or materials, or other more advanced designs. The .3mf format addressed the shortcomings of not only the STL, but also just about any other type you might think of to use in 3D printing or even thinking about 3D design: AMF, OBJ, VRML, FBX, AMF, IGES, STEP, 3D PDF, JT…you name it. The Consortium offers a handy FAQ highlighting how 3MF compares to each of these.

Overall, 3MF has now been implemented in almost 40 products across 22 companies. Six extensions have been released, like the very helpful beam lattice extension that addresses complex lattice structures.

3MF has always been an open project; the Consortium was among the original Joint Development Foundation (JDF) members. Recently, the JDF became part of the Linux Foundation — “the world’s leading home for collaboration on open source software, open standards, open data, and open hardware.”

Today, the 3MF Consortium is announcing that it is becomes a Linux Foundation Open Standards project. The new executive director is also introduced officially today, and I spoke with him to get a feel for what’s next for the consortium.

3MF Consortium Next Steps

Luis Baldez, 3D Printing Market Development, Senior Manager at HP, is taking the reins from Adrian Lannin of Microsoft, who had been the executive director since the 3MF Consortium’s 2015 founding and now will remain a strategic advisor.

Following his election to the role, Baldez faces the task of expanding on the 3MF standard’s technical progress and “building new functionalities for the standard through collaboration with Linux Foundation and the JDF,” the announcement notes. He is well positioned for these tasks, having been involved in the creation of the consortium half a decade ago.

“We’ve always struggled with the same things: trying to print something and not getting what we want because the printer misinterprets something,” he said. “STL is the most popular file type, even though it has quite a few technical limitations, but nothing had really come up to replace it. That’s when we came together as a team to address these challenges. That’s the whole story of the consortium. It’s always been driven by contributions from member companies. That was in 2014, when HP was about to enter the 3D printing market. We had our own internal file format for the printer. And Netfabb had their file format, Microsoft had their file format — so we sat down and said, ‘Hey guys, we’re all solving the same problem. Let’s solve it in a collaborative way.’ That’s how it was born. We chose to go very open, all open source, with no cost to adopt it.”

Over the years, the consortium has “come a long way in terms of defining a specification that’s technically very complete, very focused on the challenges and benefits 3D printing brings to the table,” Baldez continued.

The way the STL handles some specifications — think multiple colors and materials, and complex lattice structures — is not very efficient, so the 3MF Consortium members decided to come up with a more efficient way.

3MF Adoption

Five years into development, there’s been some tangible progress. Of course, there’s still some way to go — but not so much now on the technical side, as it happens.

“The first five years were really about building sophistications and implementing them. More than 30-40 products are registered for 3MF, but I’m finding many people aren’t aware of that. I’ve been talking to some industry influencers who don’t know this is available already. But it is, it’s all ready to go,” Baldez noted. “All the benefits are there, this more robust, more complete specification. It wasn’t like that five years ago, but that’s where we are today. The focus is on adoption now. To sum it up in one word: adoption. How do we get real users to adopt this into their workflow?”

This has indeed been an issue: there’s a strong solution out on the market, freely available…but is anyone using 3MF?

So far, the answer is yes, but. Yes, there are users, but not really enough to make this the new standard in 3D printing. Yet.

Baldez laid out a basic groundwork for increasing adoption, which starts with awareness:

“I’ve talked to really advanced users that complain about files not being watertight, about ‘this 3D printed object doesn’t match what I see on my screen,’ and I say: ‘hey, did you know this problem has been solved?’ In a few clicks, they can solve these issues.”

To heighten the awareness that there’s already a solution for these common problems out there, the 3MF Consortium plans to do more to raise the 3MF profile: more talking to media (hello!), attending more industry events, publishing more case studies for real-world examples of efficacy.

Second, the consortium will be focusing more on applications.

“This is something I’m learning more myself in my daily job,” Baldez said. “The adoption cycle is very different in the automotive industry versus the footwear industry; the challenges in the medical industry are different than in industrial. Customizing to the challenges they have and the benefits we need to emphasize and the tools we provide is something we need to really focus on.”

Application-specific support is a major focus in the 3D printing industry already. This is clearly visible especially on the software side, where companies like Materialise are incredibly strong in offering healthcare solutions, and Siemens and Dassault Systèmes have strengths in aerospace and automotive, for example. Supporting users with 3MF will involve more “catering the message to a specific vertical or mission, to really speak to the challenges that a particular customer is facing,” Baldez noted.

Color, for example, is a major benefit of what 3MF offers, but that isn’t applicable for every user. Same with file sizes; “it really relates to the specific industry you’re working in.”

3MF Consortium x Linux Foundation

One of the benefits of coming under the umbrella of the Linux Foundation is access to experience in leading adoption efforts.

Adoption, Baldez clearly noted, takes time. The need for reeducation to actually adopt new, better solutions is one that’s well known among solutions providers, and that’s “one area to leverage the experience and the brand the Linux Foundation has,” Baldez noted.

“Linux is the largest open source project out there. They’ve demonstrated through the years, with other technologies under the umbrella of the Linux Foundation, the framework and expertise to take technical expertise to the market. I’m looking forward to learning from other projects in the Linux Foundation that have taken the lessons we’re about to embark on,” he continued.

The 3MF mission was “always to maintain open source, open collaboration, all the things that are really critical to have a market expand.” Looking at the different industries that have matured over the last decade, Baldez noted, he’s looking forward to learning from web, cloud, and even blockchain learnings as these have “relied a lot on technical standards that were open sourced to a wide audience of developers and users.”

One of the most impressive aspects of the 3MF Consortium, aside from the technical aspects of an advanced 3D printing file type that actually works, is the level of collaboration and open thinking it espouses.

Getting together these big names to work together on the same project, without ego, without trademarks, is a pretty darned big deal. And that in itself points to certain aspects of the 3D printing industry that can be seen as sure signs of maturation.

3D printing is still a relatively new technology suite. The industry, however tight-knit and internally competitive it may be, is still quite small, especially compared to more established manufacturing industries. It will actually take a village, as it were, to raise this technology baby: we’re all a part of this industry, there are times we all have to work together toward a common goal.

We’ve seen this acutely in response to the ongoing COVID-19 pandemic, as consortia have arisen to work together to develop, 3D print, and mass distribute nasopharyngeal testing swabs, among other efforts — and it’s exactly zero surprise to note some overlap between members of some of those consortia with those in the 3MF Consortium. This particular effort will be much longer-term, and will also serve to benefit the many through the efforts of the few.

3MF Today And Tomorrow

3MF specs are available now. The consortium is no longer seeking Founding Members, but is focusing on users. Baldez wants to see the next stage in growth, which will be user-driven.

“In the Consortium, we’ve discussed how no one is asking for new things, but that’s because they’re not using it. When they are, they’ll find bugs, they’ll want new features. I’m hoping that moving forward as we drive adoption, this dialogue happens more often, the Consortium and members being able to work together to drive solutions that matter to the customer. At the end of the day, if the spec is perfect but is never used, it doesn’t matter,” Baldez said.

He’s hoping that, ultimately, the 3D printing industry can take another cue from the 2D printing experience. He pointed out that no one really thinks anymore about the back-end work that went into hitting file → print on a PC to make the image on the screen translate to the same thing on paper.

“The point is that you don’t really talk about the beta formats behind it: it just works reliably for any client anywhere in the world,” Baldez said. “That’s where I see the end state should be: full adoption and it just works, without any hiccups.”

Via 3MF Consortium