A company is working on a concept called “Swarm 3D Printing”.

Arkansas-based AMBOTS describes themselves as:

“AMBOTS is an advanced manufacturing company with a focus on swarm 3D printing and assembly. We look forward to bringing you to the next manufacturing revolution.”

And:

“This technology aims to automate manufacturing with a swarm of smart and autonomous mobile robots, from everyday products to houses and infrastructures. Just like how a swarm of bees or wasps would work together to build their nests, the swarm of smart mobile robots can work together to print and assemble products based on digital models on demand. AMBOTS stands for Autonomous Mobile roBOTS and Advanced Manufacturing roBOTS.”

How does this work? You can gain some understanding by examining their most recent video, in which they show a prototype system 3D printing a 1000 x 350 mm object:

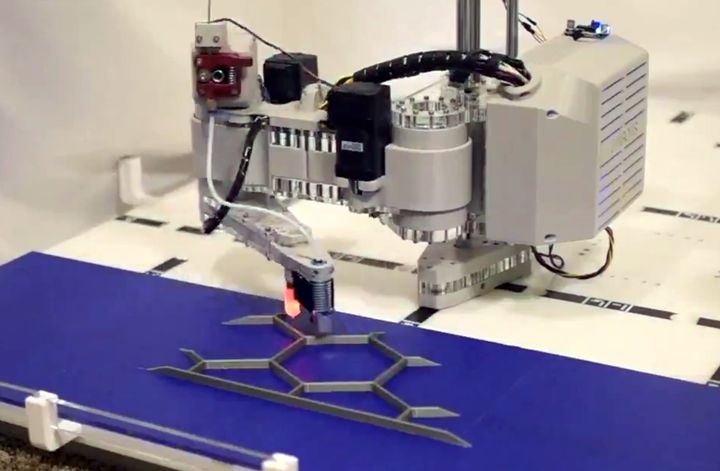

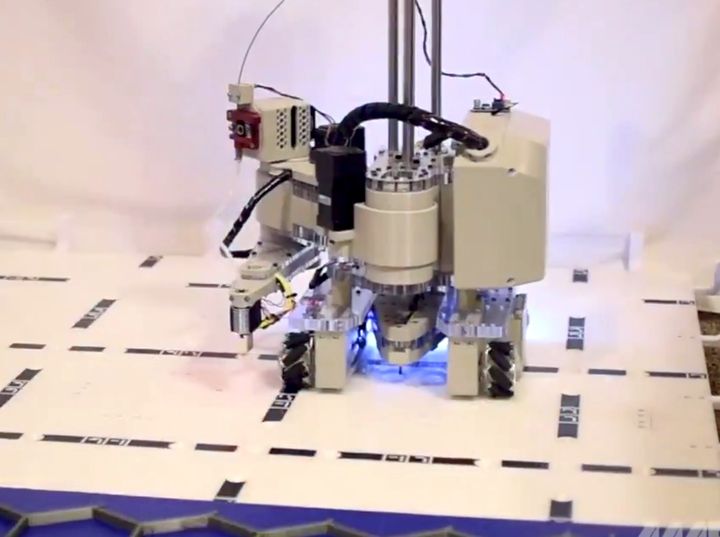

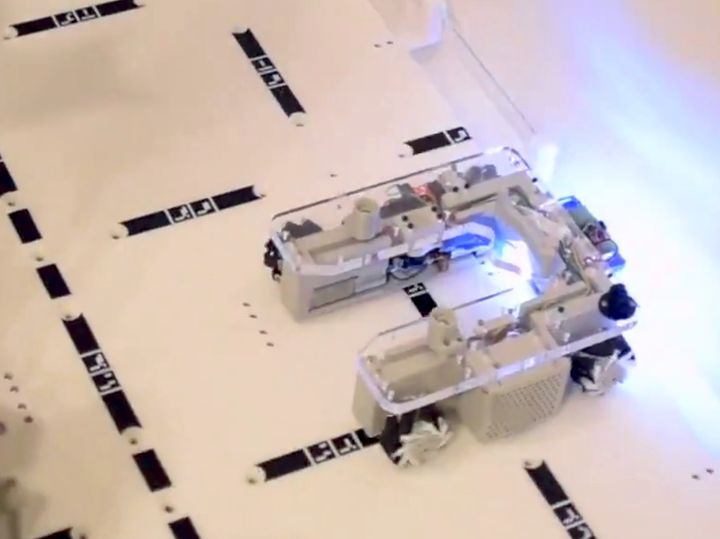

What they appear to have developed is a kind of mobile robotic 3D printing concept. As you can see in the video, dual independent 3D printers are temporarily fixed to specific locations on a grid. From these locations the devices will print within a controlled zone (which AMBOTS calls a “Chunk”).

After completing a layer of a chunk, a mobile robot picks up each 3D printer and moves them to another spot on the grid where they can then access another chunk. By moving the 3D printers repeatedly through a series of access points they are able to build the entire structure — without interfering with each other.

Swarm 3D Printing

You might not be particularly impressed by the prototype’s ability to 3D print a 1000 x 350 mm object, as there are several 3D printers available today that can produce the same type of object and in fact there are even hobbyists who have built 3D printers with sufficient build volume for that print job.

However, the AMBOTS concept is different, and let me tell you a way to instantly understand it: ask yourself “what is the build volume of the AMBOTS device?”

The answer is, well, as big as it needs to be. Or as big as the printing grid can be made.

It doesn’t HAVE a build volume. It can be as large as you want, and as fast as possible by simply adding more robots and 3D printers. Extending the build grid on which the equipment rests should be a very simple matter.

By scaling up the concept one would achieve a different kind of parallel 3D printing, one in which (potentially) a single large object could be built (as opposed to many separate objects). That’s a unique capability in the world of 3D printing, as up to now only single devices could 3D print large objects.

There have been attempts at larger-scale robotic 3D printing in which the robot is relocated periodically to build new “chunks” by others, but in those cases there wasn’t the systematic grid system as used by AMBOTS.

Should they be successful in the swarm concept, it could lead to some very unusual developments. Remember that the 3D printers being used in the prototype could easily be replaced by 3D printers with different material capabilities. For example, continuous carbon fiber could be part of the future. If that’s the case, then one could see giant carbon fiber girders being produced, and they’ve be of optimal weight due to generative design techniques. This could lead to a revolution in the construction industry, for example.

Another possibility for the future here is to add a third dimension to the printing grid. Not only would the printers be moved horizontally, but they could also be moved vertically. This could be as simple as cranking up the printing grid step-by-step to higher level, or a more complex scheme in which machines are moved to irregular levels depending on the model geometry.

With such a capability one could envision entire buildings being produced — and they’d be utterly different from the concrete construction 3D printers of today that are severely limited by the slumpy qualities of wet concrete. Overhangs would easily be possible, for example.

I think AMBOTS is on to something here.

Via AMBOTS

Swarm 3D Printing

This is a great idea and I could imagine a base on a building site marked out to position Chunks either robotically or manually but this would allow much larger printed structures and could also be used in a similar way with cranes as well. Opens up lots of ideas