Essentium announced a new solution for filament storage, the Essentium DryBox.

It’s a cabinet system that intends to maintain optimum conditions for storage of humidity-wicking materials. Many commonly used 3D printer materials tend to absorb water from the air, and this causes a number of negative effects when printed.

Wet Filament Issues

“Wet” filament has two main issues, the first being poor surface quality. The humidity absorbed by the filament is effectively boiled when the filament rides through the hot end. This generates bubbles that will inevitably appear on the surface of the print, often making a smooth surface rough. Even with a small amount of humidity absorbed by the filament, occasional blobs will appear on the print, causing the need for additional post-processing.

The other issue is perhaps more problematic. The bubbles are also present in the interior of the part, and as air isn’t a particularly good engineering material, these bubbles can compromise the strength of the printed part. When I say “compromise”, I really mean “destroy”. Some parts are essentially unusable when this happens, particularly those made of nylons.

Essentium, like many 3D printer manufacturers pursing the production market, have to eliminate this effect because production requires consistent quality output. Even if all other factors are maintained, production print quality can vary, literally depending on the humidity of the air.

Essentium DryBox

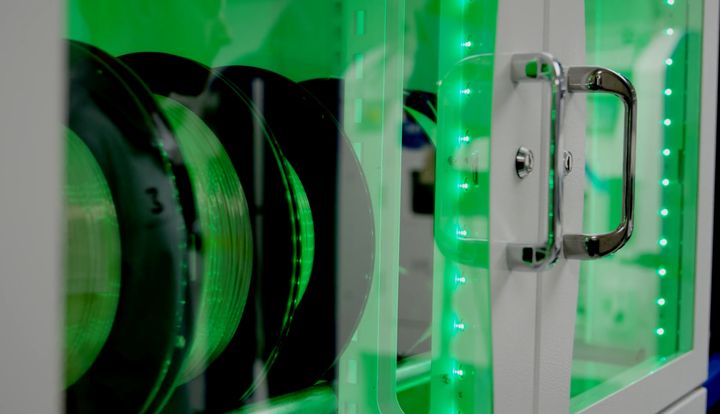

The new Essentium DryBox will overcome this. Based on the high-tech ECD SmartDry system, the DryBox will both condition and securely store filament spools.

One very interesting attribute of the DryBox is its humidity recovery time. This refers to the duration required to “get back” to the target humidity levels, and for the DryBox it is “less than five minutes”. This means you can easily open up the DryBox to pull out a spool when required without seriously compromising the humidity for the other spools stored in the DryBox. That’s important for a production operation where spools are coming and going all day long.

Of course, that implies there is more than one spool in the DryBox, and that’s the intention here. The DryBox comes in two models, the DB90 and the DB270, which is quite a bit larger. The capacities are:

- DB90 cabinet: accommodates up to 24 – 750 g spools, 8 – 2.5 kg spools or 6 – 15 kg spools

- DB270 cabinet: accommodates up to 72 – 750 g spools, 24 – 2.5 kg spools or 18 – 15 kg spools

That is enormous; you could literally store 270kg of material in the DB270 unit!

The DryBox is an intelligent system that can properly control the humidity and temperatures for a variety of material types. They explain:

“User-friendly features: incorporates a digital touch screen interface for setting desired dry storage parameters, controlling intelligent LED interior status lighting, and monitoring system conditions.”

There’s also an interesting “bake” feature that can be optionally added:

“SmartBake: an optional, integrated baking feature that can safely dry many 3D printing materials can be added to the DB90 model.”

The DryBox is a smart move by Essentium, who are most definitely pursuing the production market with their advanced 3D printing equipment and materials. But to ensure proper production the materials absolutely must be maintained in optimal conditions and that’s what the DryBox is all about.

To me, a 3D printer really can’t be considered “production” anymore unless it includes a drying feature or accompanying dry storage solution. That’s how all production 3D printing will take place in the future.

Via Essentium