SPONSORED CONTENT

Everyone knows 3D printer filament must be dry to function properly, but exactly how is this best done?

I’m looking at a ten-page piece from Essentium that dives very deep into the science of 3D printing material handling, and specifically drying.

Hold on, you say, drying filament is simple: just toss the spools into the oven and try not to melt them.

I’m afraid it turns out that rudimentary approach is not going to cut it in today’s world of advanced materials, precision prints and production end-use parts made on 3D printers.

Why is this important? It’s because many commonly used 3D printing materials will rapidly absorb moisture in the air. While the filament may visually appear to be unchanged, in fact it has been significantly corrupted. Essentium explains this effect well:

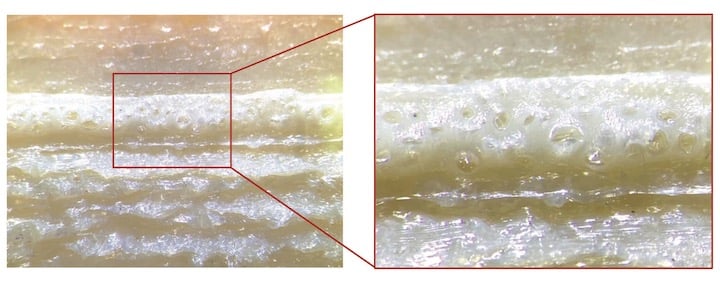

“If a spool of filament does pick up moisture, it can cause both visible and invisible defects in the material and part. Bubbles and foaming are the most readily identifiable moisture-related defects. As filament is heated in the nozzle, any moisture present in the material expands rapidly and can form millions of microscopic bubbles (foam) or larger, macroscopic bubbles.”

They provided this close up image of an ULTEM 9085 print to show how this can happen:

Clearly, the presence of these bubbles will cause changes in the part’s properties. It will be of lighter weight, but more importantly it will lose a significant amount of strength. Essentium performed some tests on dried vs. wet ULTEM 9085 and found the dry specimens were able to withstand around 70 MPa mechanical stress, while the samples made with wet filament could only withstand around 20 MPa.

That’s a notable difference — and it is quite meaningful, not only for the 3D printer operator, but for the 3D printing industry as a whole. Parts made with poorly managed filament can cause all kinds of repetitional damage. Essentium writes:

“We have seen spools of PLA and ABS hang off the back of desktop printers without any consideration for material dryness for the past decade, with plenty of satisfied hobbyists and functional industrial prototypes. Then again, we have also observed plenty of industrial users print jigs and fixtures with engineering grade materials, without drying the material, and declare 3D printing ‘isn’t ready yet’ when the machine cranks out junk.”

I learned several things from the Essentium paper about filament drying that I did not know.

One, for example, was the fact that nylon materials cannot be dried by desiccant alone. Apparently the water molecules bond to the material such that they cannot be released unless the temperature is raised. Therefore you must use a heated drying solution for nylons.

Another fact I discovered when reading their paper suggested there could be limits to the amount of drying. This is surprising, as many 3D printer operators who have “filament dryers” simply leave their spools in the dryer. Apparently it is best practice to dry the filament for a fixed period (which varies by material) and then store the filament in a sealed container. Fortunately, Essentium’s paper has a neat chart showing the suggested drying times and temperatures for various materials.

It’s becoming quite clear that properly dried filament is actually a mandatory requirement for anyone performing serious production 3D printing. This is a key element of a full quality-control system for end-use parts.

How exactly do you dry 3D printer filament? Some use repurposed dryers and others use specialty accessories provided by the vendor. Essentium describes the three major forms of drying technologies:

- Hot Air Drying

- Desiccant Air Drying

- Vacuum Drying

Vacuum drying without heat poses an interesting dilemma, as I’ve just realized it is an inappropriate drying technology for nylons due to the temperature requirement mentioned above. I wonder how many people are using cold vacuum drying for nylon material?

The Essentium paper describes an effective method of storing dry filament by repurposing a Pelican case, but they also describe their new “DryBox”, a device that can perform the required drying cycles on many different materials. It’s designed to handle all the factors mentioned above, and can handle up to 24 spools at a time in various configurations.

I’d write more, but instead I recommend you read the Essentium white paper, “Essentium Materials Handling Guide” available at their site. It gave me more information about filament drying than I had known before.

You can also watch Essentium’s 75-minute very comprehensive video explaining all you need to know about material handling and drying:

Via Essentium