SPONSORED CONTENT

The new JGMaker Artist-D desktop 3D printer launches this week, and it is quite a bit different from other low-cost 3D printers.

There are many options for low-cost 3D printers these days, but while there is a battle over price and features taking place, almost all of them have the same basic concept: a single filament extruder and build plate.

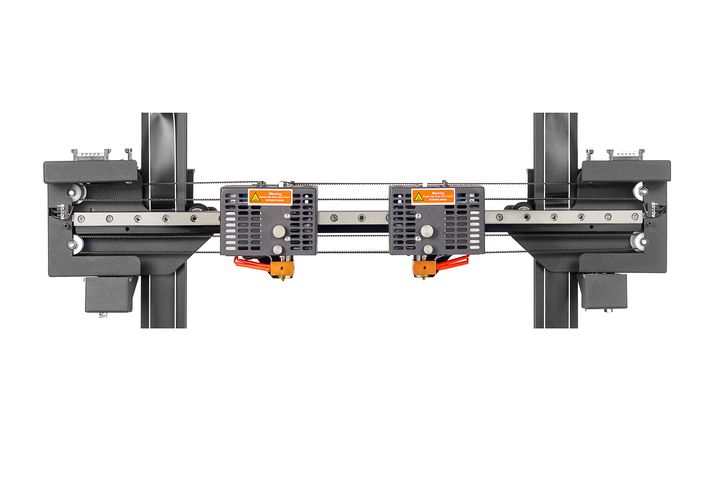

That’s going to change with the launch of the JGMaker Artist-D 3D printer. This machine, unlike most others, includes a dual independent extrusion system.

Independent Dual Extrusion

While most 3D printers have a single extruder mounted on the motion system, a few advanced machines include what’s known as “independent dual extruders”. These are like single extruders, except that there are two of them servicing the build plate and can move independently of each other.

This technology permits some unusual applications:

- Two copies of an object can be made at the same time, effectively doubling print throughput

- Different objects or mirrored objects can be made simultaneously

- Objects composed of two different materials can be produced

That last point should be explained in a bit more detail. There are indeed several 3D printers available that can print in multiple materials, but virtually all of them either have two extruders, like the Artist-D, or have a single nozzle fed by multiple extruders. The latter is inefficient because it must be flushed at each color change, effectively wasting a significant amount of material.

The usual problem with dual extruders and nozzles is that the inactive nozzle tends to drip material on the print, spoiling the finish. It seems, however, that JGMaker has solved this problem by including a “brush” that can wipe the inactive nozzle before it causes any trouble. I’ve seen this feature before on high-end production 3D printers, and it’s the first time I’ve seen it on a low-cost device.

The Artist-D can operate in four modes:

- Mono-color: Prints in one color from a single extruder, much like other 3D printers

- Duo-color: Prints a single object in two colors

- Mirror: Prints a left-right mirrored versions of an object

- Duplicate: Prints two identical copies of a single object simultaneously

The dual hot ends are rated for up to 245C, meaning the Artist-D is capable of 3D printing PLA, ABS, PET-G and other similar-temperature materials. However, it can’t print in high-temperature materials.

Artist-D 3D Printer Features

Aside from the highly useful dual extrusion technology, the Artist-D sports several other notable features.

The build volume is quite large for a desktop 3D printer, at 310 x 310 x 350 mm. This is partly due to the need to make space for the second extrusion system, but it can be used to print large single objects, too.

One very important feature is that the extruders are direct drive. This is unlike the Bowden-style extrusion that’s popular among low-cost devices, which has to push the filament through a long path to the hot end. The direct drive approach allows the Artist-D to 3D print flexible materials easily, and this could result in some very interesting prints that involve rigid and flexible components.

The hot end of the Artist-D has an unexpected feature: ejectable nozzles! By pressing a button — when the hot end is cooled, of course — the active nozzle can be ejected and replaced. This means quick repairs if there’s a nozzle clog, or the ability to change nozzle sizes easily.

One feature I quite appreciate is their attention to cabling. Apparently their design attempts to minimize the amount of stray wires and cables that can, in some other machines, catch on to the print or other objects. It seems that JGMaker has used a set of four main ribbon cables to do most of the work and they’re neatly placed out of the motion path.

Like most 3D printers these days, the Artist-D includes a “resume” feature. If power is interrupted, the machine saves its state and can actually resume the print when power returns. However, the Artist-D has a unique resume feature: it will similarly pause when the SD card is removed, and resume when it’s reinserted. This is a feature I wish other machines had — or I had the intelligence to not stupidly remove the SD card during my prints. There’s also a filament-out detection system that can pause the machine if the filament breaks or runs out.

The build plate for the Artist-D is a removable flexible surface. It’s made of manganese steel and contains an adhesive coating. This allows an operator to remove completed prints by merely flexing the plate, as the prints then pop off easily.

The Artist-D’s controller board is a 32-bit unit that is able to keep up with the double-action of the dual extruders. It also includes advanced stepper drivers that make the machine virtually silent during operation, a feature I quite appreciate when 3D printing.

Finally, the Artist-D is sold in kit form, which does help to lower its cost. However, it’s a very simple assembly as most of the complex bits have already been made at the factory, and it’s collapsed only to shrink the size of the shipping box.

You might be wondering about the fact that the Artist-D is launching on Kickstarter, where, unfortunately, we have seen many product failures. This typically occurred with startup companies who underestimated the effort required to bring a mature product to market, and they have effectively disappeared from that platform in recent years.

JGMaker, however, is a bit different. They are a large, established company that was founded over a decade ago, and have plenty of experience building 3D printers: currently they offer nine different machines using three different 3D printing processes, and have been shipping them to individuals and companies worldwide. There should be few concerns here, even if they’re using Kickstarter.

Perhaps the most interesting aspect of the Artist-D is its price. While other independent dual extrusion devices may cost thousands, the first 500 Artist-D units will be sold at only US$339, an incredible deal for a dual independent machine. That’s a discount price for the launch, of course, as it will rise US$599, which is still an incredible price.

If you’d like to experiment with an independent dual extrusion 3D printer, this may be your chance to do so at low cost.

Via Kickstarter