The MAAM program intends to commercialize the world’s largest additive manufacturing machine for the production of large parts to be used in industry and for defense.

The Award

The Air Force Research Laboratory (AFRL), Materials and Manufacturing Directorate, Manufacturing and Industrial Base Technology Division has decided to award the National Center for Defense Manufacturing and Machining (NCDMM) and Center Street Technologies (CST) a funding of over $9.4 million to join hands in a two-year effort to support the Massive Area Additive Manufacturing Program (MAAM).

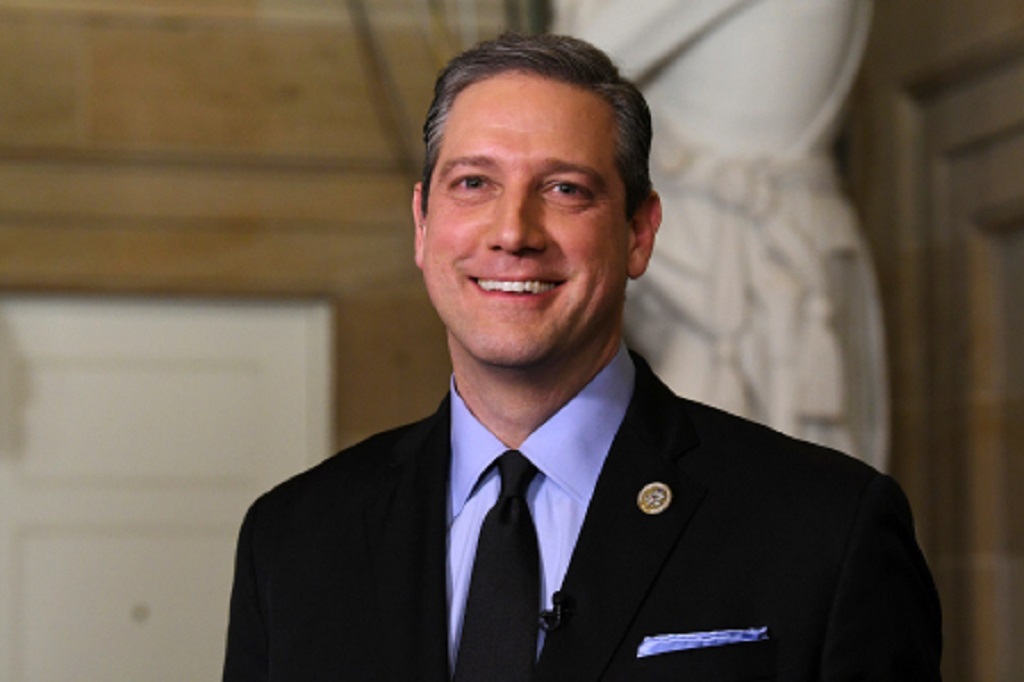

The announcement of this event was made last week by the United States Representative Tim Ryan at CST’s Youngstown facility. Congressman Ryan, who is a part of the Defense Subcommittee of the U.S. House Appropriations Committee played a significant role in the direction of the funding towards this partnership. The funding was a part of the FY 2020 federal appropriations bill and it is believed that furthering the MAAM technology paves the path for its commercialization, so that high paying jobs can be created locally in areas like Youngstown and the Northeast Ohio region.

“I am proud to have been able to use my position on the Defense Appropriations Committee to secure this important funding for our community,” Ryan says.

He continues this explanation by saying, “Additive manufacturing is transforming every sector of our national economy and it is clear that Ohio, NCDMM’s America Makes, and Center Street Technologies are leading the way. This funding will be instrumental in expanding our manufacturing base and growing good paying manufacturing jobs here at home.”

The announcement:

Leading Up To The Reception Of This Funding

Earlier this year, CST had revealed its masterpiece — world’s largest additive manufacturing machine. This machine was designed with the aim of producing large parts for industrial use, like in the commercial automotive, energy, construction/civil engineering, and maritime industries.

The discovery caught the eye of the AFRL and the Department of Defense (DoD) primarily because of its ability to produce large quantities of quality, high value products quickly and efficiently. Plans note that this MAAM system is to be located at the Youngstown Air Reserve Station.

CST’s Response

Mike Garvey, the President and CEO of CST, explains the significance of the funding in the following statement:

“This funding will be used to catalyze broad scale commercial adoption of leading-edge advanced manufacturing technologies developed in Youngstown, Ohio, by folks from Youngstown. Together with NCDMM, we intend to make this project a historical event so that when future generations look back on the community’s prosperity, they will directly land on these types of projects Congressman Ryan supported and nurtured.”

NCDMM’s Response

Back in 2012, NCDMM introduced one of their most successful programs, America Makes, to Youngstown. In recent years, the city of Youngtown has come to light for their contributions to the additive manufacturing world as a result of the success of America Makes (the DoD’s additive manufacturing innovation institute) under NCDMM’s management.

“Congressman Ryan has worked tirelessly to revitalize Youngtown’s and the Northeast Ohio region’s manufacturing sector,” NCDMM’s Vice President and Chief Development Officer, Randy Gilmore, also acknowledges Ryan’s efforts. “He understands the transformative economic potential that advanced manufacturing technologies like additive bring in the form of new companies, innovative products, and positions for skilled workers. With AFRL’s funding, NCDMM’s advance manufacturing expertise, and Center Street Technologies’ one-of-a-kind system, the MAAM Program is poised to make a significant positive impact on Youngstown, Northeast Ohio, the commercial industrial sector, the defense industry, and our nation’s military readiness.”

The Partnership’s Future

I think that there’s a lot of ways that both the Air Force and the Department of Defence could benefit from this partnership, because they both have the need for large-scale manufacturing. The 3D printer developed by CST would allow large objects to be custom printed SPECIFICALLY to the needs of the departments concerned, which is one of the biggest advantages in practically all parts of the 3D printing industry — the ability to customize, reduce costs, and make any quantity of objects.

Overall, I’m excited to see the things that they come up with using the funding that they have been provided.

Via NCDMM