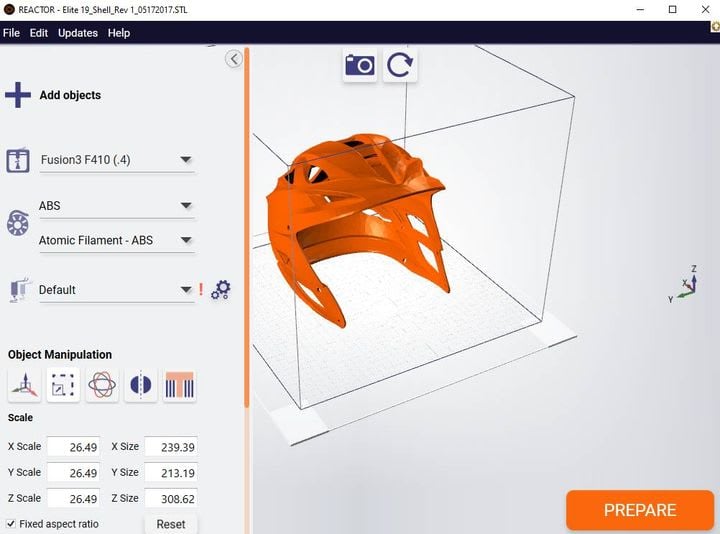

Fusion3 has introduced a new and powerful slicing system for their 3D printers, REACTOR.

REACTOR is based on Create it REAL’s REALvision slicing engine, and is intended for use only with Fusion3’s set of 3D printers. REALvision includes a number of proprietary slicing algorithms that can significantly increase the quality of 3D prints.

I should note that REALvision, the core of REACTOR, is definitely not a rework of an open source slicing system, as are most of the other options you’ll see from 3D printer manufacturers. This is not Cura, nor SLIC3R under the covers. It’s an entirely new-built software system from Create it REAL.

On the surface, REACTOR offers the usual slicing system functionality, including ability to layout 3D models for print jobs, application of “modifiers” to tweak settings in certain regions of the print job, and much more.

However, the secret sauces are deeper inside REACTOR. One of them is the aforementioned REALvision algorithms, but another is print profiles.

3D Print Profiles

3D print profiles have definitely caught on, as the first companies that introduced them have wildly succeeded. The idea is that instead of having the 3D printer operator guess and iterate through various print parameter settings to discover the optimal configuration, the proper settings can be supplied in advance.

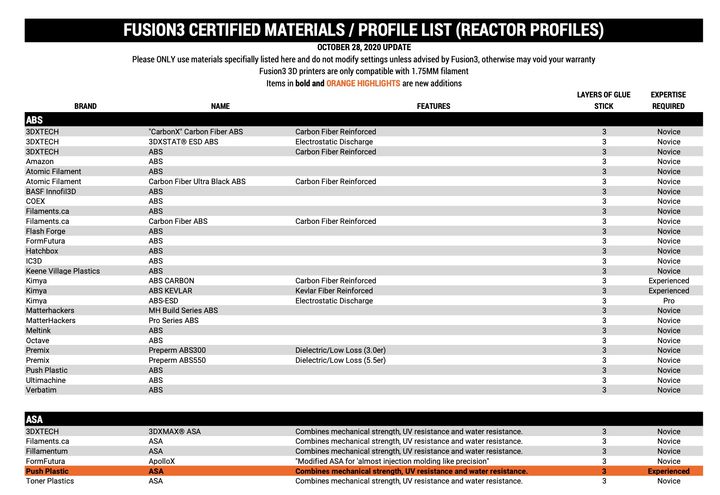

Print quality, however, is a combination of equipment and materials, and so a print profile will always be a set of print parameters for a specific machine AND a specific material. And by specific material, I mean a specific filament product from a specific vendor, not “Generic ABS” or similar.

A good print profile is always the goal, but by integrating a library of them into a slicing system a vendor can dramatically increase the utility of their equipment. This is because the 3D printer operator merely selects the right profile for the job and runs it. There is little need for iteration, and this saves not only operator time, but also saves on material that would otherwise be wasted in experiments to dial in the settings.

At this point it’s becoming clear that to properly compete in the professional 3D printing market a vendor should have this type of functionality available for clients.

REACTOR Profiles

The inclusion of 3D print profiles in REACTOR seems to be the major feature, as the benefits above would immediately be available to Fusion3 clients. Even better, the system would be able to constantly improve by including new profiles into the system as they are identified by Fusion3. This means the software will “keep up” with newly announced advanced materials.

How extensive is REACTOR’s print profile library? I took a look and found almost 140 different specific 3D print materials available in Fusion3’s catalog, representing around 40 of the leading filament suppliers. These included material options for ABS, ASA, Co-polyesters, Flexible, HIPS, Nylons, PETG, PLA, PC, and “Other”.

Now, recall that a print profile is a combination of material (from the 140 above) and machine. These materials would all have a profile for the current Fusion3 flagship 3D printer, the F410. It’s likely that if and when Fusion3 launches another 3D printer, it would also have profiles associated with it embedded in REACTOR.

Using REACTOR

REACTOR is bundled with Fusion3’s F410 3D printers only, and you cannot purchase it for use with other equipment. In fact, it’s considered so valuable that Fusion3 has an online activation procedure to manage licensing, which can also be done offline for those in secure locations.

Simplify3D and Fusion3

Up to now Fusion3 has bundled Simplify3D with their equipment, as do many 3D printer manufacturers. When asked if they would be discontinuing Simplify3D, Fusion3 CEO Chip Royce told us:

“We have been valued partners with Simplify3D since 2014, with the launch of our first 3D printer, the F306. A number of factors, most importantly the desire to pursue unique features driven by the interaction between the software and hardware, led to our setting this course. Our current customers have the option to continue using Simplify3D if they choose, and we will continue to offer Simplify3D as an option for those customers not yet ready to make the switch.”

This is quite interesting. It seems that Fusion3 felt that REACTOR would be a better option than Simplify3D, and perhaps this is because of the centralized print profile features. I’m wondering now whether the folks at Simplify3D, who have yet to offer an upgraded version for now well over two years, are considering adding that feature into their software.

In any case, it seems that Fusion3 is now well-positioned to compete in the professional market with their powerful F410 machine and equally powerful slicing software, REACTOR.

Via Fusion3