We catch up with Dr. Thomas Reiher, cofounder of AMendate, who is now director of Hexagon’s generative design division, in his office in Paderborn, Germany, to find out more about what MSC can do in terms of generative design—perhaps the most promising but overhyped design technology of the future.

MSC Software, the company best known for the most successful version of NASTRAN and at its peak, and the last generation’s leading simulation vendor with an unassailable leadership in the aerospace industry, has been undergoing decades of changes in product lines, new management and ownership.

In 2014, MSC seemed to enter a competition with itself by launching an alternative to NASTRAN, the Apex CAE product line.

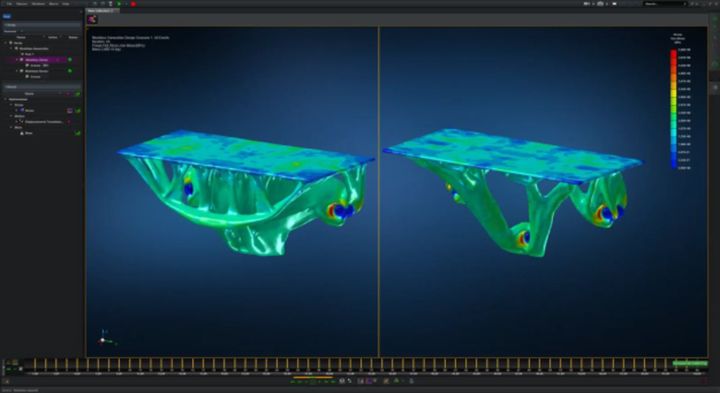

In 2017, the company was acquired by Hexagon AB, a Swedish firm best known for metrology and also known for its aggressive pace of acquisitions. Hexagon bought Intergraph in 2010 and would go on to buy Bricsys in 2018. And bringing us to our story today, in June 2019 the company acquired AMendate, a German generative design startup.Another stringy-looking part typical of topology optimization software. This EDAG LightHinge+ claims a 70 percent weight reduction from the original design, along with 40 percent lighter weight and production time that is reduced by 60 percent compared to “conventional” optimization with Apex Generative Design.

MSC was headquartered in Southern California (Newport Beach), but a recent CEO is in London, the current CEO is in Brussels, Hexagon is listed as Swedish, you are in Germany.… Where does Hexagon consider the home of MSC?

Hexagon is all over the world. Paolo Guglielmini, our former CEO, lived in London. I think we do not have this one certain headquarters for MSC anymore. We have different subsidiaries, centers of excellence, which have different headquarters. For the additive manufacturing world, the senior technologists live in Hamburg and in Belgium.

How did the acquisition of AMendate come about and your role?

MSC did not have a generative design product for a long time. MSC needed this tool. They knew they needed something new in this area and especially something dedicated to additive manufacturing. They wanted to make sure they were providing it in addition to their competitors. I’m responsible for generative design now and AMendate, the company I cofounded, is the back-end intelligence behind MSC Apex Generative Design.

I was the founder and CEO with the idea for all of this, but I’m just an engineer and not in software development, so my colleague Steffan Vogelsang did all the coding.

Can you tell me what led to the naming of AMendate?

It comes from a Latin word to improve, optimize with A-M for additive manufacturing.

Did MSC have no generative design before AMendate?

No. It has a little bit of optimization inside NASTRAN. Apex is a CAE platform. Before, users had the Apex modeler and structures for standard CAE. Now, with AMendate, it has generative design as well.

AMendate was a stand-alone product?

Yes, it was stand-alone when we were a startup. It originated from my PhD thesis on the optimization of design for additive manufacturing, and together with my colleagues at AMendate, we developed the code.

The program was command-line driven. We believed a good generative design needed to be part of an automated engineered process with a close connection to the other simulation tools and with manufacturing—all part of a perfect design.

Read more at ENGINEERING.com