We’ve written previously of NASA’s incredible 3D printing experiment taking place on the International Space Station. Now we’ve seen a real example of how the technology should work.

The orbital 3D printer was designed by startup Made In Space, who, over the course of several years developed a plastic filament-based 3D printer capable of microgravity operations. The unit was launched a few months ago aboard a SpaceX Dragon cargo voyage and has been undergoing rigorous testing.

But now a different scenario has occurred, according to a report on Medium’s Backchannel: a 3D printed object has been printed on-demand in orbit.

Made In Space’s Mike Chen says their team overhead the ISS Commander, currently US Astronaut Barry Wilmore, indicate he required a ratcheting socket wrench to complete a task. Made In Space took the initiative and quickly designed a 3D model, relaying the resulting file to the station. Smartly, the Made In Space team converts the raw 3D model to printable GCODE before they send it to the station, thus relieving the already-busy orbital crew from the peculiarities of 3D printer slicing software.

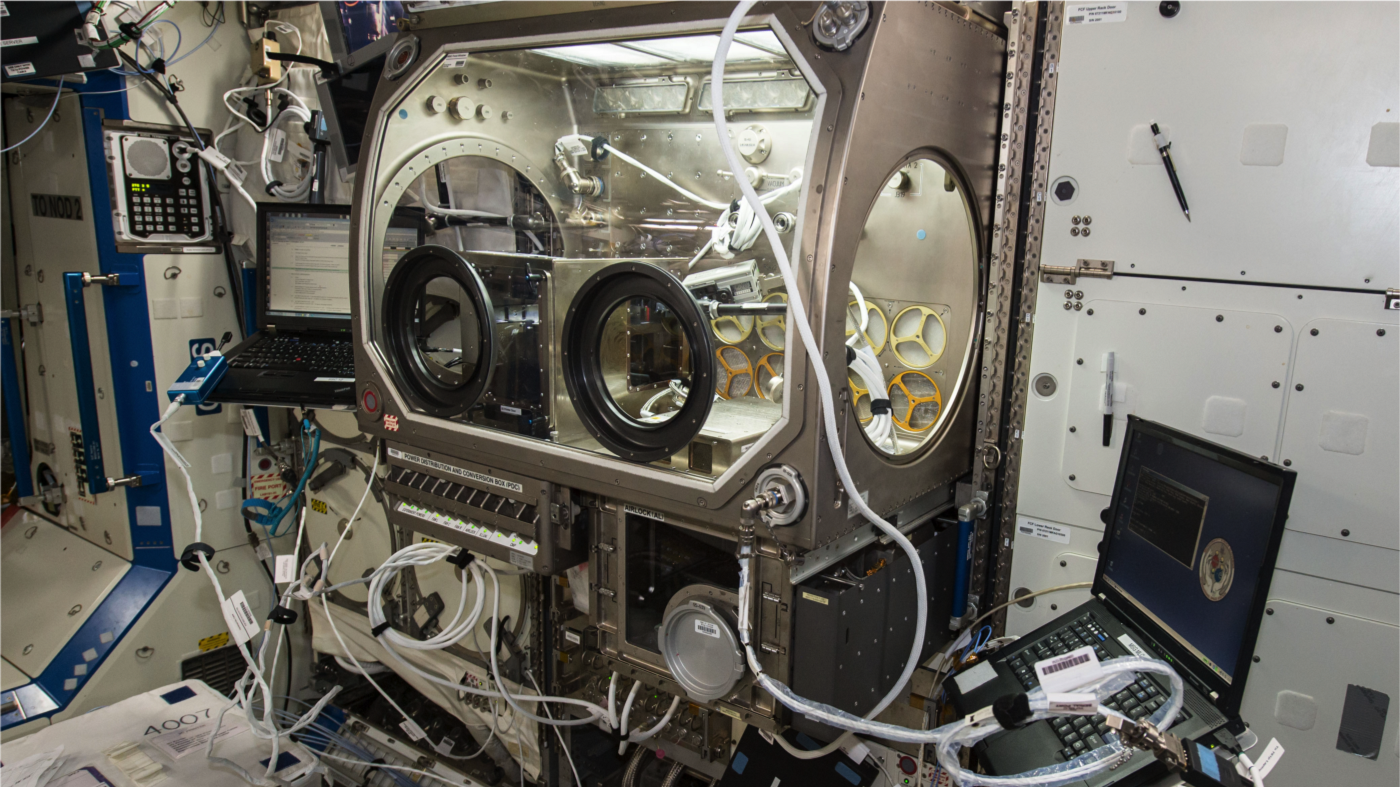

The file was then successfully 3D printed in orbit, as you can see in the image at top. As far as we know, the is the first instance of “transmitting” an object to outer space.

It’s like a slow version of Star Trek’s teleportation. Read the full story below.