Fuel3D announced a new “mirror” 3D scanner that could lead to advanced eyewear applications.

The company has long been developing 3D scanning equipment based on an unusual high-speed structured light system. Initially they produced a very effective 3D face scanner, the Scanify, used for both 3D printing and in 3D gaming.

Since their introduction in 2013 they’ve branched out into a much wider variety of 3D scanning applications, including a rather large unit we tested at CES earlier this year.

Now they’ve announced a device that’s designed specifically to 3D scan faces for generation of custom-fit eyewear. The new device is embedded within a mirror, which causes subjects to act more naturally, resulting in a higher quality 3D scan.

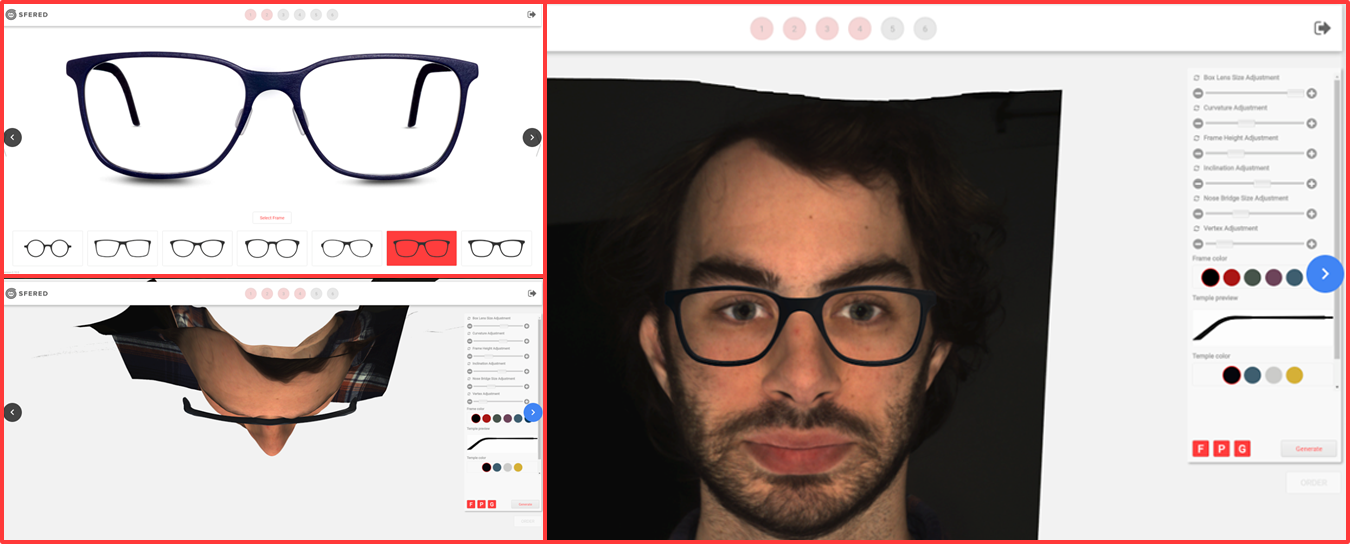

The device was developed by Fuel3D in partnership with two other companies. One was Sfered, a Netherlands-based company specializing in development of eyewear technology, and Monoqool, a maker of “innovative eyewear”. Between the three parties they certainly had the knowledge to put together a device that can accurately capture eyewear measurements: Fuel3D to collect scan data, Sfered to provide knowledge of the eyewear machine environment and Monoqool for eyewear designs.

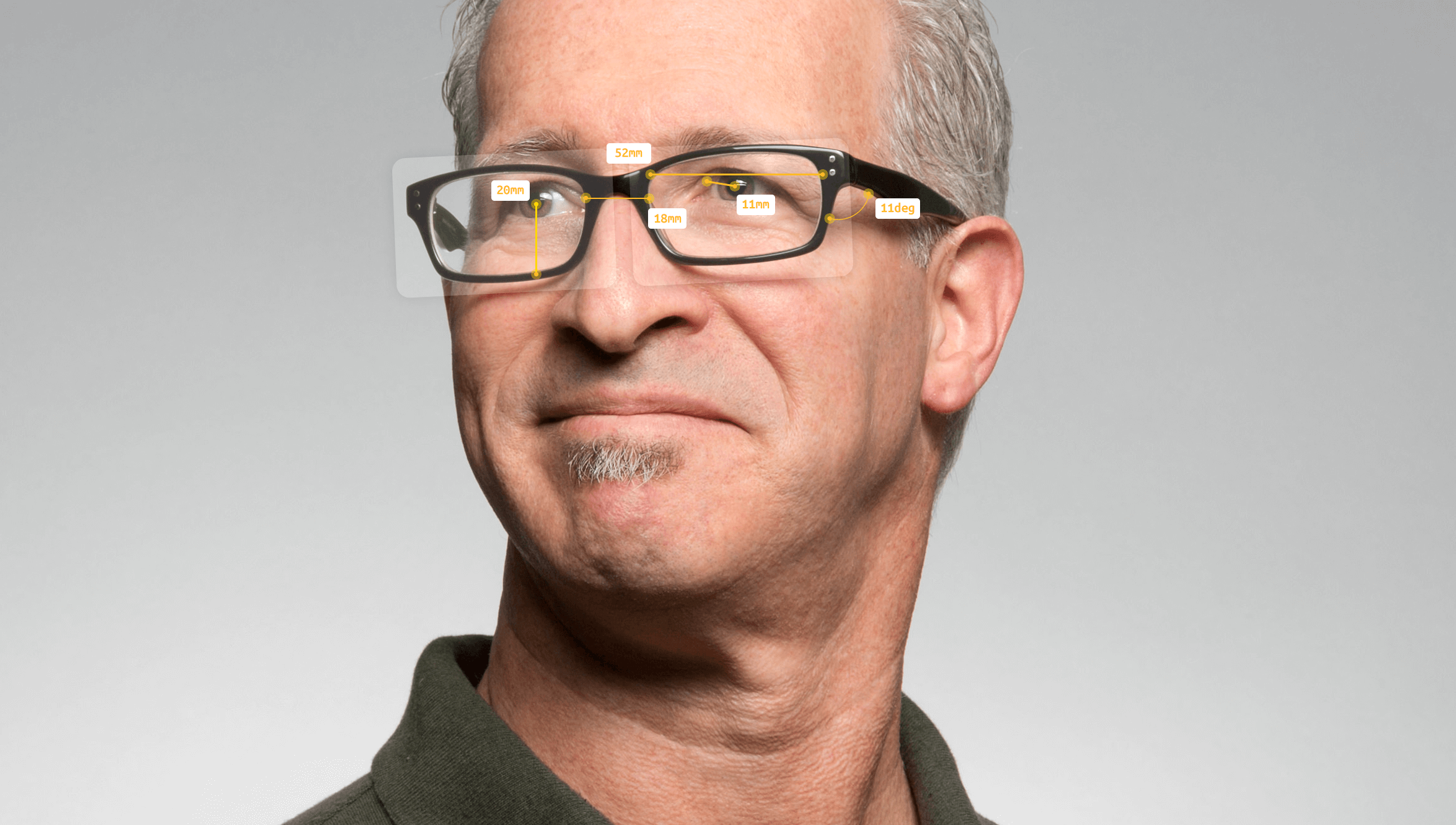

The device, seen at top, can capture highly accurate scans within 0.1 seconds, far shorter time than a wobbly eyewear customer can move significantly. This is an important aspect of Fuel3D’s success, as some other solutions require motionless subjects.

And it’s not just a machine; the idea is to actually 3D print custom eyewear that perfectly fits the buyer. Not only can the measurements be precise, but the styles can be chosen through software. The idea is that this technology could be theoretically present in every optometrist office worldwide, which could reach a staggering USD$165B by 2022, according to Fuel3D.

If they’re successful, it could be a milestone in retail industries looking for customized solutions. For example, would footwear stores follow suit with similar equipment? What about clothing vendors? It could be the start of something big.

Via Fuel3D