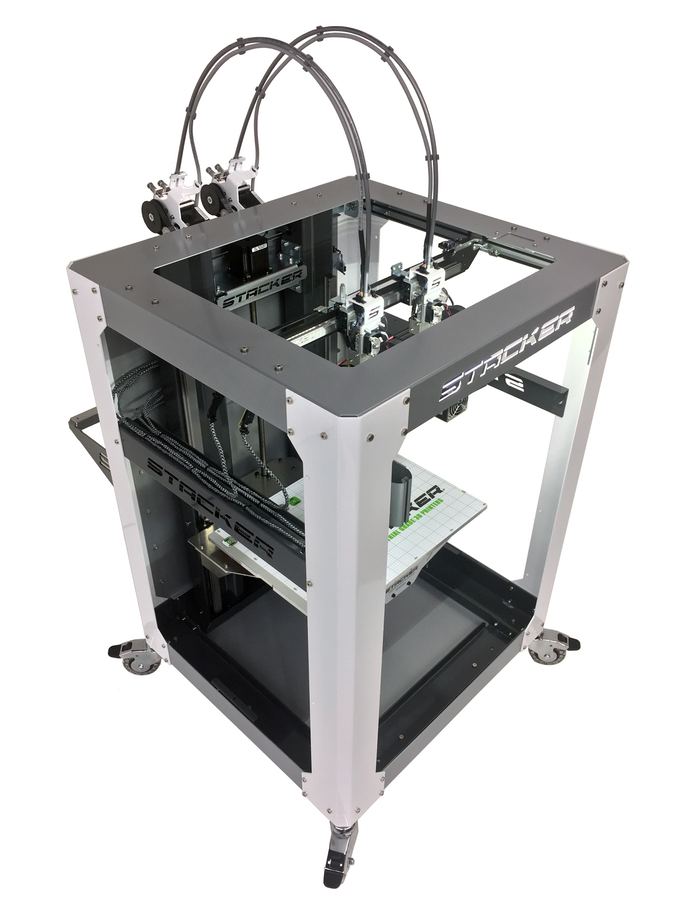

Two years ago a new company called STACKER introduced a powerful four-head professional 3D printer. Now, they’re back with a newly optimized model, the S2.

Launching today, the S2 includes two print heads rather than the four provided on the original S4 (see how their product naming strategy works?) But the utility of a machine isn’t simply a statistic like the number of print heads. No, it appears that STACKER has done some appropriate market research here.

They’ve correctly identified that a prime market for less expensive 3D printers is institutions, like schools and professionals. They’re definitely not the first to do so, as there are countless other 3D printer manufacturers scrambling for that market.

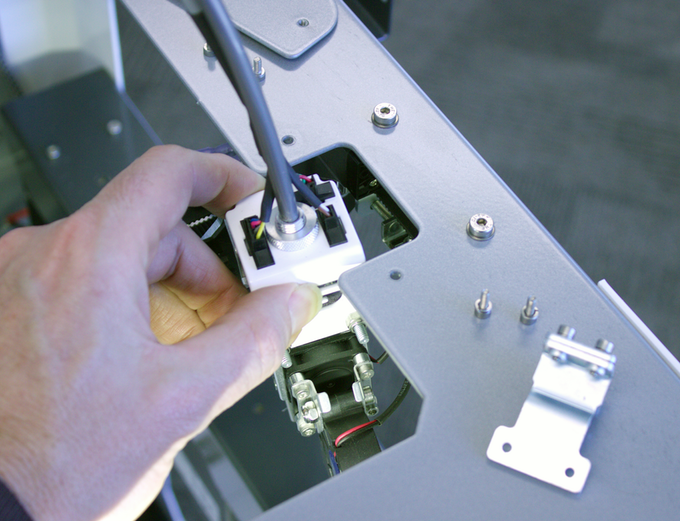

But it seems that STACKER has done some research and determined that features such as the quantity of print heads is NOT what this market seeks. No, they’ve instead determined that the prime concerns are reliability and maintainability. Thus the S2 is engineered around those principles. They explain:

The S2 fills a void in the market by providing a true industrial grade 3D printer that is not only affordable to purchase but affordable to operate. The S2 requires no service contract and exceeds the print quality of printers costing thousands of dollars more. For users currently printing with hobby grade printers, the S2 is a huge upgrade in performance and reliability, with pricing well within their budgets.

It seems that STACKER has redesigned the innards of their system based on their previous experience with the S4 to achieve these design goals.

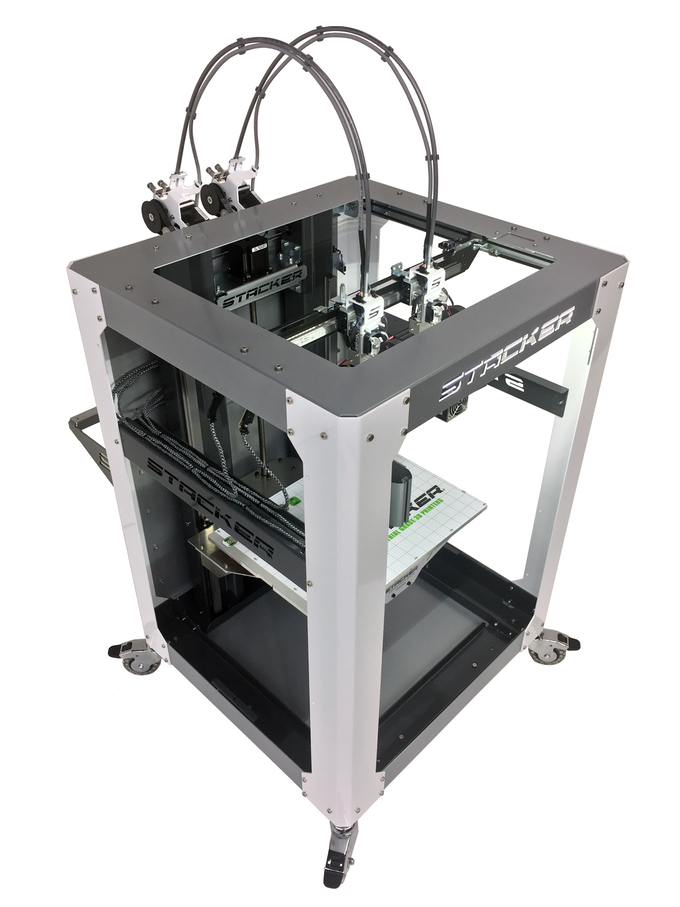

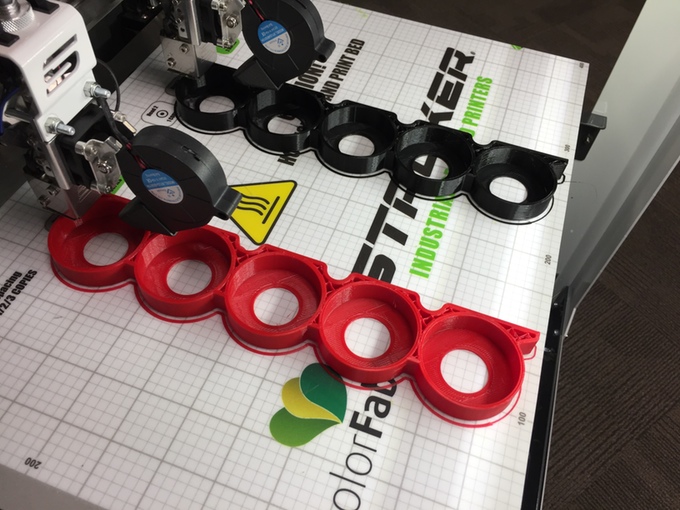

That said, the S2 does have impressive specifications, with the most notable feature being, ironically, print heads. The two print heads are different from most equipment in that they are independently operated. This means the S2 can operate in three modes: two print heads building a single model twice as fast; building a model in two materials; two print heads building two identical models at twice the normal rate. All very useful modes.

The S2 is set up to be portable, as it is set upon a cabinet with wheels permitting it to be easily moved about, within a school, for example. This indicates to me that they’ve spent time in the target environments to identify simple, but key required features.

The portability is fascinating in that the S2 has quite a large build volume, at 175 x 315 x 525mm. Now I must explain there is a complication with the build volume: when two print heads are engaged, one head blocks a portion of the path of the other, slightly reducing available print volume. This is a common problem on most dual-head machines, who must state multiple versions of their build volumes to explain the situation. However, the S2 has a unique feature: you can temporarily remove one of the print heads to instantly increase the build volume to the full potential.

A very useful feature on the S2 is its ability to 3D print a very wide set of materials, ranging from common PLA and ABS to exotic materials such as PETG, flexible filaments and composite materials such as wood filament. Again, the idea here is to eliminate concerns from the operator, things that typically plague less expensive units.

The S2 is available for pre-order on Kickstarter commencing today. Pricing, as is customary on Kickstarter, will gradually rise as units are acquired. The initial batch will go for USD$4,995, rising to USD$7,495 as sales progress. A 3D printer of this capability for under USD$5K is a pretty good deal, particularly with all the features available on the S2.

And as always, I must issue a caution as this is a crowdfunded project, many of which have recently failed, leaving the backers at the side of the road. Each campaign is different, but of those I’ve seen, STACKER has a very good reputation, having not only successfully executed a prior campaign, but in the interim have successfully produced and delivered equipment to clients, and made deals with other companies in the space. (One of their partners, colorFABB, is mentioned no less than 18 times in their campaign!)

Professionals and institutions might want to take a long look at this machine, as it seems fit for your purposes.

Via STACKER and Kickstarter