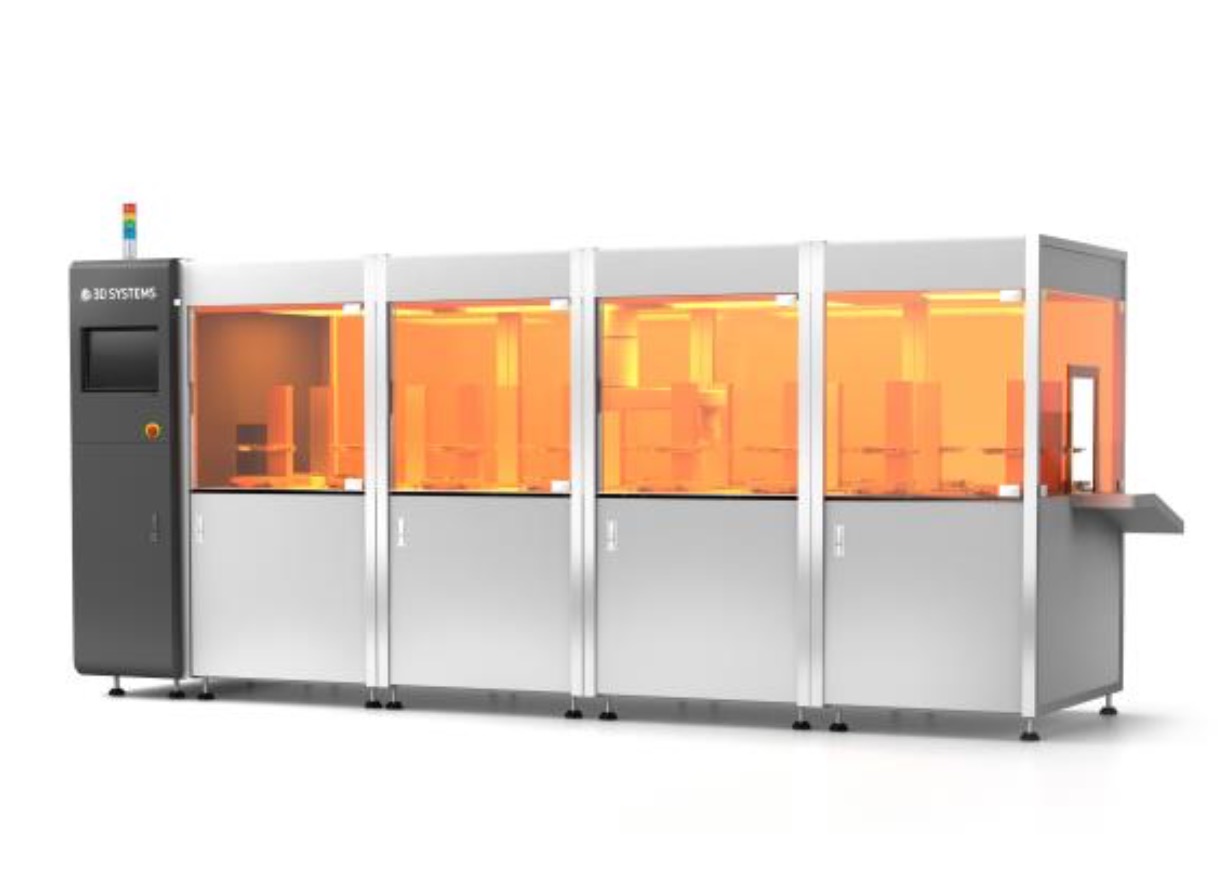

3D printer manufacturer 3D Systems finally announced perhaps the worst-kept secret: the Figure 4 Production Platform.

The machine – or early versions of it – were prominently displayed in 3D Systems’ booths at a number of widely attended exhibitions, so it is not at all surprising they finally have put the machine onto the product shelf.

So far, the company has shipped the very first Figure 4 to a “Fortune 50 industrial customer”, and hopes to ship quite a few more systems during the latter half of 2017.

The Figure 4 Production Platform is named for a specific diagram in the original 3D Systems patent filed decades ago by Chuck Hull, inventor of the SLA process. The diagram showed a production process that is more-or-less what today’s Figure 4 Platform does, hence the unique name.

The Figure 4 concept is quite interesting, as it is a combination of SLA 3D printing technology, robotics and other processing elements. Essentially, the system is able to robotically take a print through a series of processing stations where actions take place to complete the manufacturing process.

It can do so repeatedly, essentially being a full production system for certain kinds of parts. I related this in a post previously, where I had observed a demonstration unit producing literally piles of parts at a trade show. This concept can very quickly turn out large quantities of parts.

In the Figure 4 concept, a print could be produced, and then automatically moved to a washing station, a post curing station, paint station, electroplating or whatever manufacturing process is required for the particular item. Of course, 3D Systems does not offer all of these options yet, but it would be relatively easy for them to add practically anything into the Figure 4 pipeline.

And that leads the price of the system. I cannot say what it is because this isn’t like a typical 3D Systems product, where a single machine is involved. The Figure 4 Platform is a system in which a collection of different modules in differing quantities is assembled to meet the requirements of a particular manufacturer. Thus the pricing is entirely variable and dependent on needs. It’s really more like a toolkit than a product.

The price of the system is actually far less relevant than you might imagine, however, as the Figure 4 Platform boasts some incredible efficiency advantages, according to 3D Systems. They say, for example, that the cost per part could drop by up to 71% due to the reduced labor requirement, no doubt. Parts are produced 14.1X faster, with 1.5X less waste. Overall they say the labor cost is reduced by 4X. These are very significant improvements.

Finally, let me talk about 3D Systems’ competitor, Stratasys, who also have also taken a step towards large scale production with their demonstrator units. It seems that both of these companies recognize the future for their activities: production at scale.

Two companies, two different production strategies. But it appears that 3D Systems’ has hit the market first.

Via 3D Systems