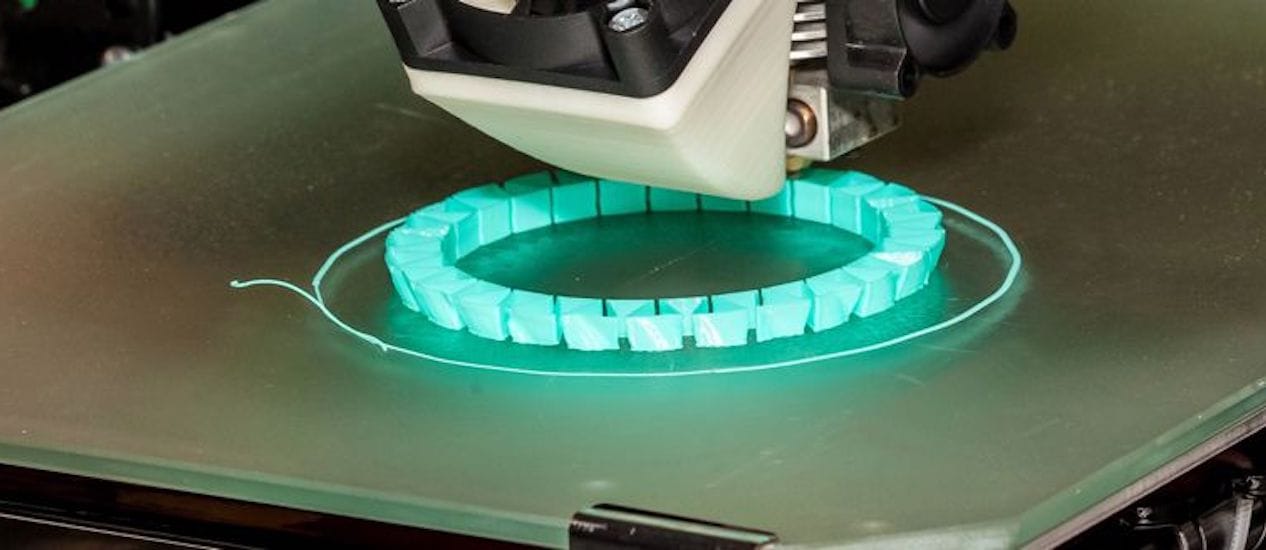

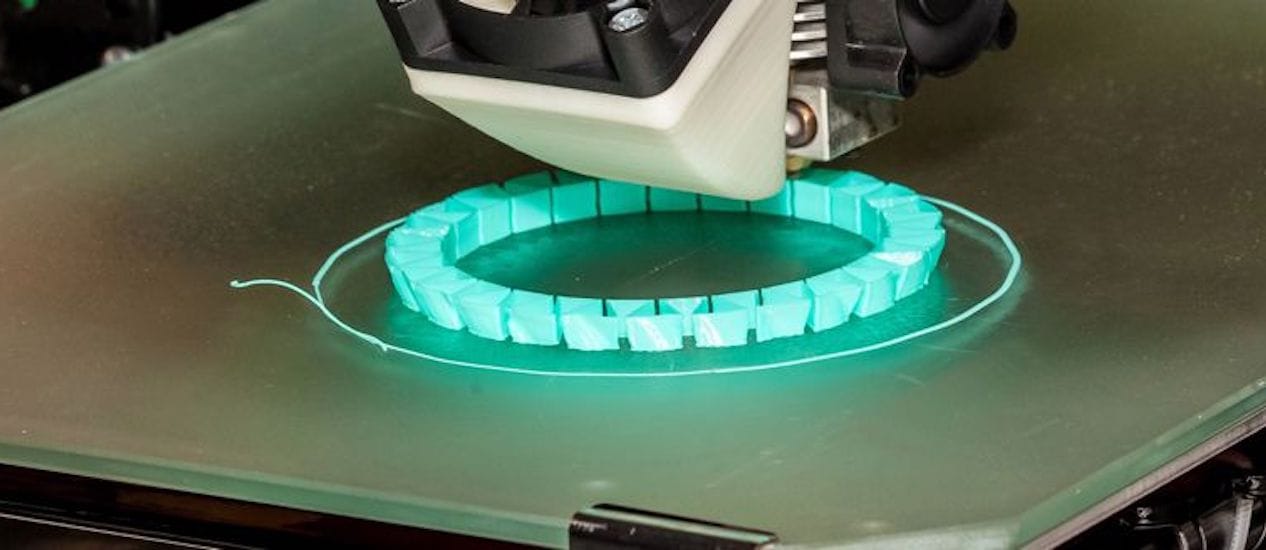

I just noticed that chemical giant DuPont released new materials specifically for 3D printing.

Everyone has heard of DuPont; they have been around since 1802 (that’s 18-02, not 19-02!) and have over the decades grown to one of the world’s largest chemical companies. Among the many products they produce is polymers, which are of course just another mix of chemicals.

DuPont owns a huge catalog of industrial polymers, having developed such familiar materials as neoprene, nylon, Corian, Teflon, Mylar, Kapton, Kevlar, Tyvek and Lycra. And that’s just the ones you may have heard of; there are a great deal more available from DuPont.

Recently DuPont announced they’ve made three of their polymers available in filament form. They are:

It combines resilience, and heat and chemical resistance with strength and durability. Parts made with Hytrel® thermoplastic elastomer resin can flex in multiple directions, cycle after cycle, long after rubber would break. A prime example is the Constant Velocity Joint (CVJ) boot, an automotive component that is subject to an average of 150,000 miles of pounding, and a wide range of temperatures.

The DuPont™ Zytel® nylon resin portfolio of PA6, PA66, PA1010 and PA612 products is produced by the largest, most globally networked nylon manufacturer exclusively focused on the resins market. Zytel® Plus nylon resin offers higher performance levels and maintains them much longer than traditional nylons despite exposure to hot oil, hot air, calcium chloride (road salt), automotive coolant and other aggressive automotive chemicals. Renewably-sourced Zytel® RS nylon resins offer more sustainable solutions.. And, when you’re looking for a metal or thermoset replacement, or your current product falls short of a particularly stringent requirement, DuPont™ Zytel® HTN high-performance polyamide may well provide the ideal solution.

A leading choice for food, cosmetic, medical device, and skin and stretch packaging— as well as in golf balls and industrial applications. Known for its outstanding clarity, toughness, and light weight, DuPont™ Surlyn® ionomer resin is a reliable, cost-effective solution for a range of innovative packaging and other applications.

For food packaging, Surlyn® provides low-temperature seal initiation, excellent hot tack strength, and puncture resistance. It seals through contaminants, helps reduce leakers, and increases line speeds. For cosmetics and medical device packaging, it provides clarity, formability, and scratch resistance. It is an attractive, lightweight alternative to clamshell and blister packaging. Surlyn® is also used as the surface layer for golf balls, ski boots, and overmolded bottles. Its processing options include blown film, cast film, sheet, extrusion coating, and injection molding.

These are powerful polymers that will surely be welcomed into the professional 3D printing market by those prototypers looking for advanced materials performance.

However, to me this is a bit more important as this announcement is a strong signal that a very major chemical company now recognizes 3D printing technology as a market to be served.

In past years, desktop 3D printers were largely fueled by re-purposed material such as “ABS welding wire”, rather than products specifically designed for 3D printing. Now that’s changed entirely as a large number of vendors have been furiously inventing a wide variety of filament products specifically for professional desktop 3D printing.

DuPont’s announcement is the next step: where a company holding the recipe for huge numbers of unusual materials unleashes it on the 3D printing world.

I expect two things to happen: DuPont’s filament products will appear on the product shelves of many filament resellers, particularly because of DuPont’s worldwide distribution system, which can easily overcome the regional constraints encountered by most smaller filament manufacturers.

And secondly, I expect DuPont to begin releasing additional materials as they see opportunities to arise.

Via DuPont