3D print software Simplify3D has been updated to version 4.0, which contains a boatload of very powerful 3D print control features.

If you’re not familiar with Simplify3D, it is a third party 3D print preparation software package, meant to replace the relatively weak slicing software that came with your desktop 3D printer.

Their goal is to provide much more control over how the print is achieved to increase print reliability, surface finish and part functionality. This is done by including features to detect particular features in the 3D model presented and use appropriate speed, flow and temperature settings in ways not usually found in common slicing systems.

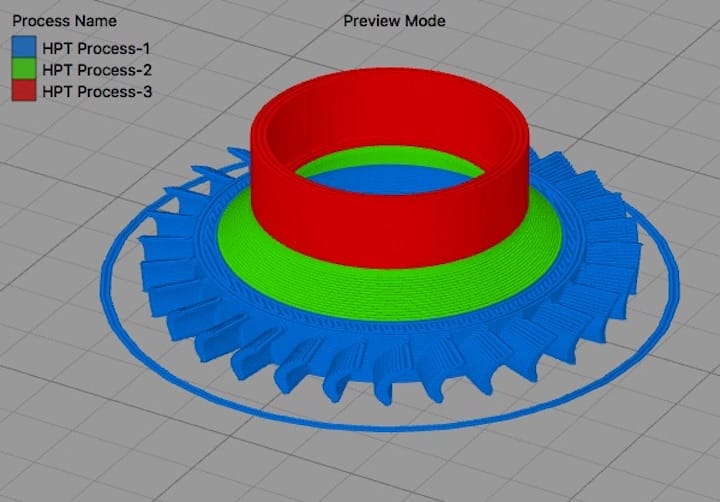

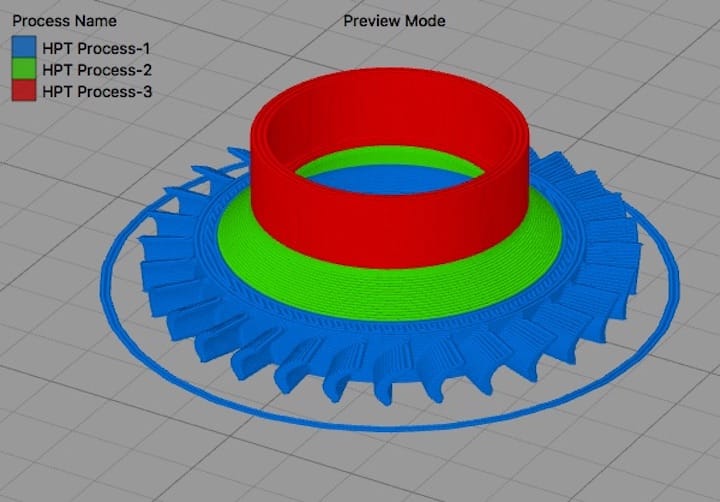

These print configurations are stored as print “processes”, in Simplify3D which contain all the specific settings. They can then be used on different 3D models, shared with others and modified for use with new materials.

While previous versions of Simplify3D have offered more ways to 3D print than typical 3D print software, their new 4.0 release seems to go way beyond even that to approach or even attain a professional capability. That is to say, engineers developing functional parts using new high temperature professional desktop 3D printers would likely find much of interest in this release.

But what new features are included? Simplify3D has published an entire page listing the major bits, but it seems that they have constructed methods to dynamically control the extrusion rate and have used that to develop several powerful new features.

The main change is that you are now allowed to employ multiple processes in different sections of a 3D model, with the new “Variable Print Settings” feature. This means that you could, for example, make a bolt hole and surrounding area very strong, yet have a lightweight area elsewhere in the 3D model. And you can combine many such processes in a model, seemingly with little restriction.

The software also generates what they call “Seamless” transitions between the different processes as they emerge on your 3D prints.

There’s a great deal of other features, some major and some minor. Here are a few that caught my eye:

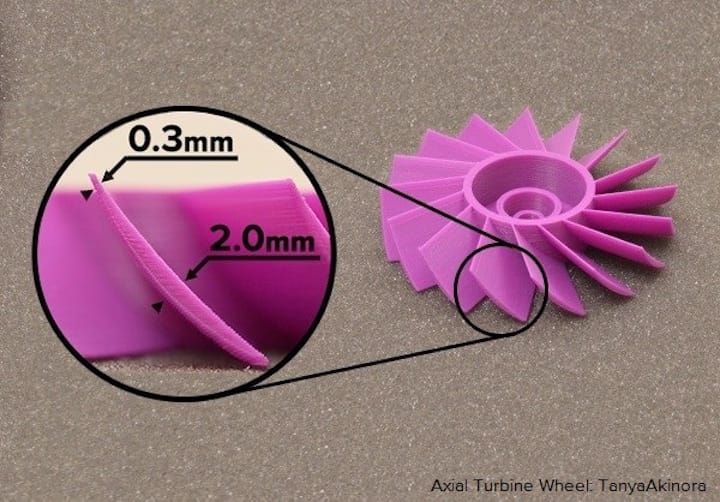

The “Variable Extrusion Sizing” feature allows a change in the diameter of the extrusion dynamically. This means that portions of a print could use strong, coarse extrusions, while other finer details could be printed with thinner lines.

The example used by Simplify3D to illustrate this capability is a propeller, which requires a very sharp blade edge. Simplify3D 4.0 can use thinner extrusions at the blade edge to accomplish this.

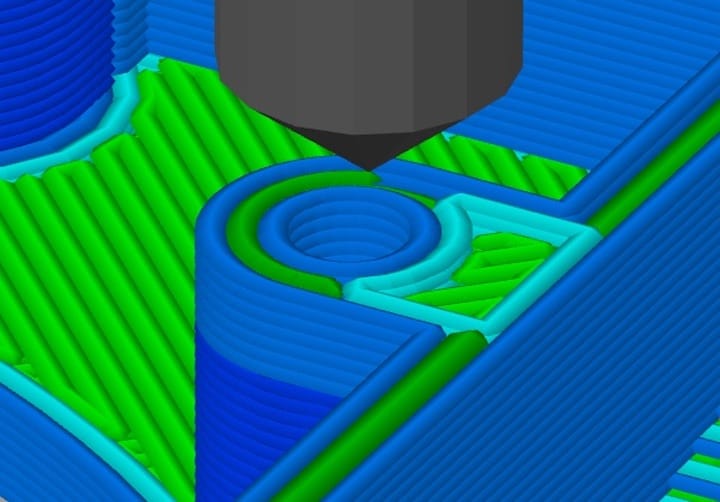

This delicate control over the extrusion size has been deployed in another powerful feature: “Dynamic Gap Fill”. Here those maddening gaps where the size is just smaller than the extrusion width are actually filled!

In most slicing systems you will find unsightly and part-weakening gaps in situations where, say, you have a wall of thickness 2.5X the extrusion width. In that example, you get a 1X wall, a 0.5X gap and a 1X wall.

In this scenario, Simplify3D will simply shrink the size of the extrusion to fit the gap as best it can, resulting in a more complete print.

Their support structure generator has also been improved to optimize the amount of supports required. Simplify3D says that this can reduce your support material by up to 50%, which is significant as it will also reduce your print time. For those who print a lot, this alone could justify your investment in acquiring a copy of Simplify3D.

There are tons of other minor improvements, such as being able to select the bridging direction, or reducing mesh complexity, but overall this appears to be a very solid set of additional functions, and I suspect it may take Simplify3D users a while to get used to them.

Finally, the best part of Simplify3D 4.0 is that it is available at no charge to existing users; simply head to your Simplify3D account and download the new version to upgrade. For those who still don’t use Simplify3D, you can get yourself a fresh copy of 4.0 for USD$149. More expensive than free open source software, yes, but with features you can’t find that could make your 3D printing a lot better.

I plan to upgrade soon and take a long look at these new features. Expect a deeper story on this soon.

Via Simplify3D

1 comment

Comments are closed.