I’m reading about the interesting collaboration between Polar 3D and Printrbot, who together have produced something they call the “Printrbelt”.

It’s a very unusual design for a desktop 3D printer, but one that I’ve recently seen in a couple of similar projects. It’s a way to 3D print objects continuously!

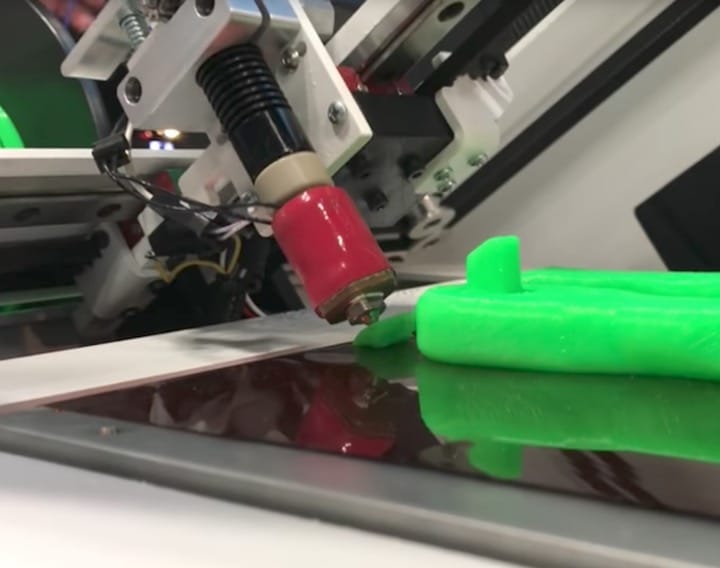

The X-Y axis is tipped at an angle, and the Z-axis is a continuously moving belt. Objects are effectively printed sideways, where they eventually roll off the end of the belt into a bin for post processing.

The belt is heated, and appears to be covered with kapton tape, a common adhesive material that also happens to be flexible, just the thing to make into a belt loop.

The Printrbelt’s specifications are, aside from the fact that it prints SIDEWAYS, pretty normal: 30-60mm per second print speed, 0.2mm layers, 1.75mm filament, etc.

Build volume is not specifically mentioned on Printrbot’s page, but the Z-axis I know already: infinite! So long as you have a method of catching the print, you could theoretically print forever if you had sufficient input filament spools.

I’ve actually used something like this many years ago, as MakerBot had an attachment for their now-prehistoric Thing-o-Matic that included a belt. This amazing community innovation was available for a while seven years ago, but it had a fatal flaw.

The flaw was that the belt very quickly wore out. Being subjected to high heat, the belt deformed and even though tightly wound, it would have very serious bubbles that compromised printing.

Will the Printrbelt suffer the same fate?

It appears not, as the kapton seems to be layered on top of a more robust belt. This approach allows the belt to be as strong as necessary without concern for adhesion, like the MakerBot option had to do.

As I said, this is definitely not the only sideways 3D printer I’ve seen recently:

Stratasys announced an “infinite build” demonstrator that literally prints at a 90 degree angle, and in industrial sizes, too.

More recently, Stratasys announced a “continuous build” demonstrator that prints vertically (normal) on disposable sheets of build material that come off a roll, somewhat similar to the Printrbelt.

Uniz provided us with a sneak peek of their sideways resin 3D printer, which has not yet been released. It can also print larger objects, but not continuously.

Finally, there is the European Blackbelt concept, which is very similar to the Printrbelt, albeit quite a bit larger.

Now for the interesting stuff, that seems to have been ignored by all of these folks save Stratasys: how do you drive this continuous 3D printing capability?

In the old MakerBot concept, it was pretty rudimentary. In my case, I simply took the GCODE for a print, added the “eject” codes to the end of it and then pasted N copies of that together. Once a print was done, it ejected the completed model and then started on the next. But there was a limit to how many prints you could get, and it was pretty hacky.

Polar 3D and Printrbot have obviously given this some thought, as they have decided to offer Polar 3D’s cloud-based print dispatch system along with the Printrbelt. This is an online print queue, which normally is near-useless for 3D printers as you must have a person unload the prints before the next print starts anyway.

But with a continuous build system, there IS a need for the next job to be immediately dispatchable. That’s what Polar 3D is doing in this deal: you can literally pile up a very long series of prints and the cloud system will dribble them out to the Printrbot, which runs unattended.

That is, until you run out of filament. I suspect buyers of the USD$1,999 Printrbelt will opt for large 2kg spools of material.

Via Printrbot