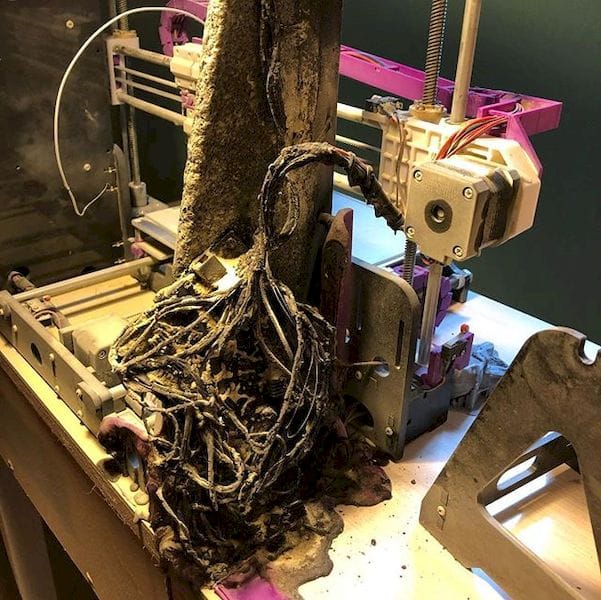

![A severely burned Anet A8, again [Source: Ben Ridgway]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09ff806984.jpg)

Once again, an Anet A8 desktop 3D printer caught fire.

The incident occurred when 3D printer operator Ben Ridgway attempted to 3D print an object in PETG for 11 hours on his heavily modified Anet A8. Evidently something shorted out and a fire resulted in the damage you see at top.

Ridgway explains what happened:

“I fell for the allure of the Anet. I am new to 3d printing. I was looking for a printer that was relatively inexpensive and I could learn on before investing in a nicer one.”

And

“After dozens of mostly flawless prints I was getting cocky. I was leaving it unattended for longer and longer times. 10-hours into an 11-hour PETG print and my wife goes to the gym while I’m at work. She returns to find my beloved Anet engulfed in flame. Luckily she was able to blast it with a fire extinguisher and put it out. If she had been home a few minutes later the fire would have jumped into the wooden walls and our house and two cats would have been gone.”

Wait, you say, “heavily modified” may mean Ridgway messed up the machine and that must have caused the problem?

Well, no. In fact Ridgway was quite aware of the notorious reputation for the Anet A8, which has caused multiple fires in various locations, some of which have been reported on this publication.

Ridgway was determined to modify the machine to include a number of safety features that are missing from the original manufacturer’s design. In a post on Reddit, he explains what he changed:

“I read about and had implemented all of the safety and performance upgrades. I was using a MOSFET for the bed, fused the power supply, had attached fans, and had printed cases and wire guides for everything.”

And

“A MOSFET with a big heat sink was driving the bed

Wires to and from the bed, MOSFET, and power to the main board were all 14 gauge with quality spade connectors and shrink tube.

The bed connector was stock, but people said that the V2 bed didn’t have the same connector problems as v1. It came with 14 gauge wires to which I added spades at the FET.

The X and Y axes had cable chains and strain reliefs on both ends.

I printed cages and secured the wires for both the power supply and main board.

The power supply was fused (5amp) and switched.

80 mm fans attached to both the power supply and main board.

Both extruder fans were upgraded/replaced after they died.”

The Anet A8 in particular is known for fire risk, likely due to lower-grade components being used. In some cases the power flowing through the cables can exceed the rating, and thus electricity may jump out onto other components. But the most damning issue with early-model A8s was that their firmware did not include thermal runaway detection.

This issue occurs when the thermal sensor is somehow disconnected from the controller. The controller then sees a low temperature, and as it’s been instructed to raise the temperature of the nozzle, it applies power to the hot end, endlessly, because no feedback is received. Thermal runaway systems can handle that and similar situations and shut down the system appropriately. More recent Anet and other competing low-cost Asian system are increasingly including this feature, which to be honest, should have been there from the first moment.

The ongoing nature of these incidents strongly suggests that safety aspects are a low priority among some low-cost 3D printer manufacturers. It’s thus reasonable to suggest that you should not be buying low-cost 3D printers unless you are fully capable of detecting design problems and fixing them, and this leaves out virtually all of the market targeted by the manufacturers.

To be clear, desktop 3D printers are devices using multiple moving parts and very hot temperatures; it is always possible for ANY 3D printer to go awry. It’s just that some are a lot more likely than others to do so.

My advice is to steer clear of any device or manufacturer that has gained a reputation for less safe equipment.

Even so, you should consider:

-

Proper ventilation for your 3D print workshop

-

Install smoke detectors nearby

-

Have fire suppression equipment handy

-

Do not leave long prints unattended

-

Remove flammable items from spaces nearby the printer

-

Consider purchasing a safety-featured enclosure

We’ve published many stories on 3D printer safety over the years, and I am sad to see we must do another one. Someday, in the distant future all manufacturers of 3D printers will consider safety their number one concern.

But that day is not today.

The last word goes to Ridgway:

“The rumors are true. That device is dangerous. Friends don’t let friends buy ANETs.”

Via Reddit

1 comment

Comments are closed.