An Italian company has announced another “infinite” 3D printer, and I’m wondering if this approach is going to stick.

Up until the last year or so there was only one concept for 3D printing, regardless of technology: the print had a maximum size, based on the build volume of the machine in question.

That changed with the sudden appearance of at least two new machines exhibiting a different motion system that, in theory, allowed the printing of infinitely long objects, so long as one could supply input material and handle the ever-growing object as it emerged.

Another interesting side effect of this approach is that the need for some support material is reduced. The tilted nature of the extrusion means there are situations where support may not be required.

One was Stratasys’ “Infinite Build Demonstrator”, a large and complex device that leveraged their FDM extrusion technology, but turned it on its side and enabled printing of large objects. Stratasys is targeting this device at the manufacturing industry, where very large unique parts could be quickly produced.

The other was the BlackBelt 3D printer from a Netherlands startup company. This approach was somewhat similar to Stratasys’ in that printing occurs sideways. Or at least on an angle, in Blackbelt’s case.

The angled print mechanism allows extremely large prints to take place, as the belt moves the print along, exposing more vertical surface to print on. It can also be used as a kind of factory, as smaller prints can be continuously printed and removed by the belt, allowing “mass” production to take place.

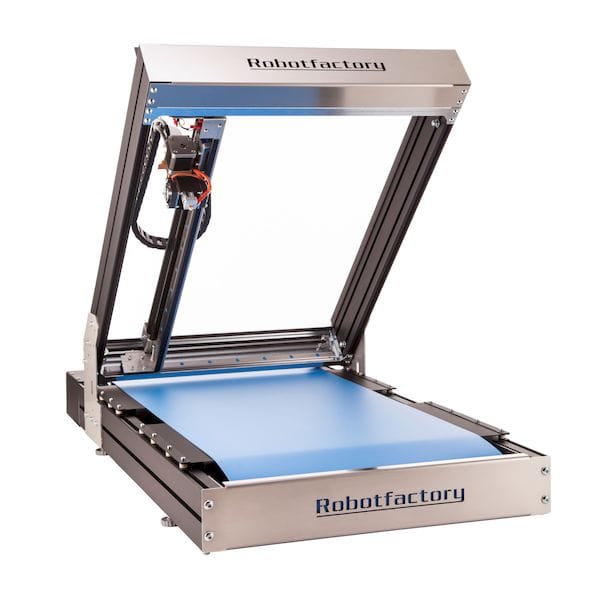

Now we see another company taking on something very similar: Venice-based RobotFactory has announced the “Sliding 3D” printer, which uses a conveyor belt and angled extrusion approach.

The Sliding 3D has a build volume of 410mm x 380mm x well, infinite! The 410 x 310 refers to the XY area, which is normally visualized as flat on the ground. However, in this case that XY area is tilted as you can see in the picture below.

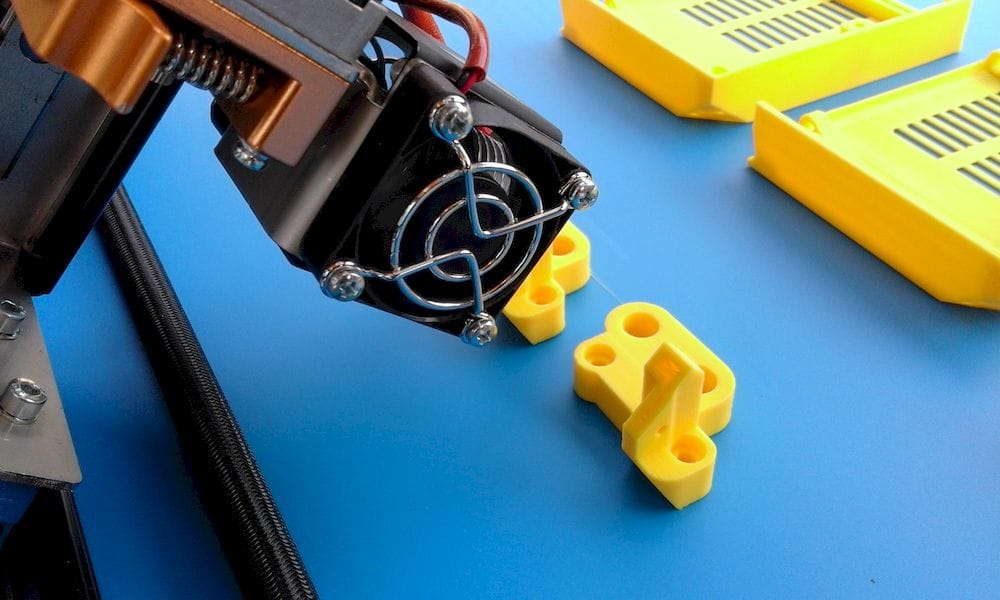

The heated bed underneath the conveyor system combined with the up-to 280C hot end means the Sliding 3D will be able to 3D print materials beyond mere ABS and PLA, such as nylon, HIPS, PETG and others.

Thankfully, the Sliding 3D comes with interchangeable hot end nozzles. The standard nozzle is the normal 0.4mm size, while they also offer 0.6, 0.8 and 1.0mm nozzles for coarser, but faster prints. These will be especially usable for the larger prints that will inevitable take place on this machine.

The system will accommodate 2.2kg spools, decreasing the manual intervention required to swap spools when one is consumed. However, I did not see a filament-out detection system included, so you may have to watch the machine when it gets close to the end of the spool.

Curiously, the control mechanism for the Sliding 3D is set in a small external pad shown here. I’m not certain of the reason for this, but perhaps it has to do with emerging large prints being beyond arm’s length of the machine itself.

Software recommended for the system is Simplify3D, although the company apparently does not include it with the Sliding 3D. They do, however, provide a usable configuration file for Simplify3D.

Optionally you can purchase an enclosure for capturing ambient heat and increasing the reliability of 3D printing operations. I thought an enclosure would be problematic on such a machine, as the long prints might demand a very large enclosure.

However, as you can see in this image on the right, the enclosure seems to include a kind of curtain through which completed parts can fall. I suppose you will have to supply your own parts bucket to catch them.

It’s not clear whether the Sliding 3D is currently available for purchase, nor what the price might be – although you can enquire on their website.

For me this is a very interesting development. Could it be that with this machine we are now seeing another style of 3D printer arrive in the market? Will others produce similar “infinite” machines?

While the Sliding 3D is now out, it seems that Blackbelt 3D has increased its staffing recently, suggesting they hope to succeed with their version.

And, has anyone patented this concept?

Via Robotfactory