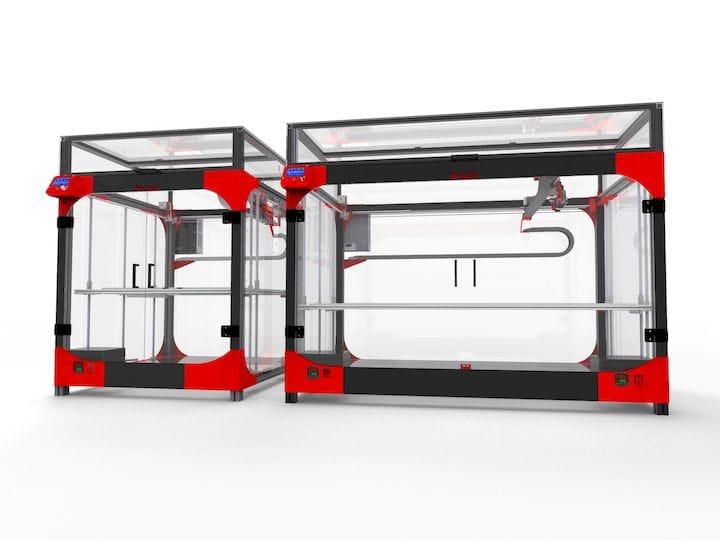

![The gigantic new Modix X120 professional desktop 3D printer [Source: Modix]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a69ede057.jpg)

There are large-sized 3D printers and then the really big ones. The Modix X120 is one of the latter.

Modix is an Israeli company that’s been making professional desktop 3D printers for several years, with their flagship machine being the Modix Big-60 Version 2.

It’s a thermoplastic extrusion machine using open filament, but its key feature is obviously its build volume of 610 x 610 x 610 mm. That’s just about the largest professional machine on the market.

However, they are about to release an even bigger machine, the X120.

The new machine, to be shown first at next week’s TCT Show, will sport a build volume of 1200 x 600 x 600 mm. Yes, that’s 1.2m in width!

The X120 will inherit many of the key features of the smaller machines, including:

-

E3D-Online V6 Hotend

-

E3D-Online Titan extruder

-

Linear rail system

-

Optional full enclosure

-

Swappable nozzles, with 0.4, 0.6 & 0.8mm brass sizes included

-

Solid aluminum Alcoa Mic6 print bed

-

100 point (!) automated leveling system

That last point is interesting; As the size of the build plate increases, more sensor points are obviously required to account for all the differences in the surface contour. For example, on a Prusa i3 with 200 x 200 mm bed, there are 9 sensor points. The Modix X120 has a print surface 18 times as large, clearly showing the need for additional points.

It is apparently possible to upgrade an existing Big 60 to the larger X120, but it seems to me that it would be a significant surgical operation to do so: the machine would essentially be disassembled as the X-axis frame would be replaced. This means disconnecting almost everything. However, for those sufficiently adept it would be a fun project.

The X120 itself ships as a kit and you must assemble it yourself. The machine does not appear to be particularly complex and so this should be doable by many.

Modix sells the previous model starting at US$3,500 (with more cost for the optional enclosure). The new model is to be priced at US$6,000 for launch, with the upgrade kit at only US$2,500.

The pricing on this unit is very interesting, as it is significantly lower than some other large-format machines, although it is marketed as a kit. The addition of the enclosure makes the machine far more capable to 3D print difficult materials, although it may still be challenging to 3D print large parts in ABS.

The competing large-format 3D printer manufacturers have all found great success in that market, so it will be interesting to see if Modix follows that same path.

Via Modix

Modix has upgraded their line of large-format 3D printers to what they call “version 3”. But that version actually includes a huge list of powerful improvements.