SPONSORED CONTENT

Filaments.ca is introducing a new food-safe line of 3D printing filament.

3D printing has proven popular for creating unique designs for cookie cutters and cake toppers, bringing personality to baking, as well as for more utilitarian tasks such as customized kitchen tools for restaurants, bakeries, and home cooks alike. Special care must be taken, though, for any 3D printing projects that will have contact with food, as both material and 3D printing process must be geared toward these applications. Contamination of material or finished product is a big concern — and a new line of food-safe filament was created with these concerns in mind.

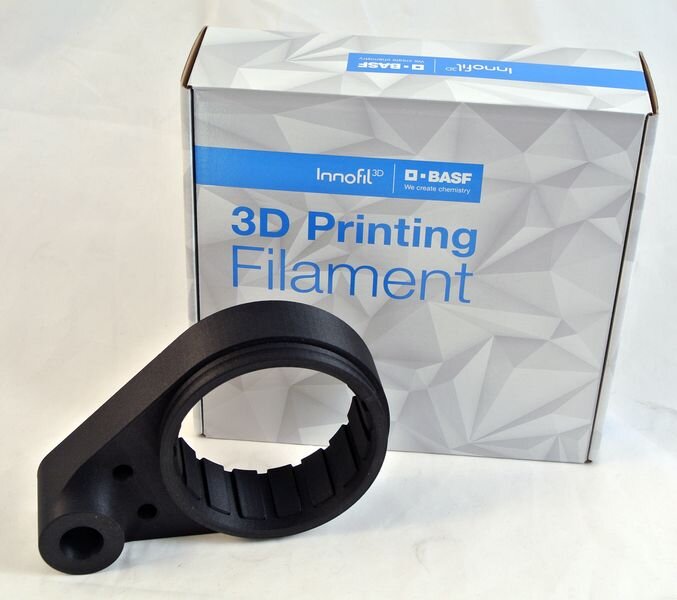

Starting with PLA before expanding to other materials including PETG, Filaments.ca’s new material line is set to bring the benefits of 3D printing into a wider variety of delectable applications.

TRUE FS PLA is specifically manufactured from the very start with food safety as a key production component. While Filaments.ca has always employed Good Manufacturing Processes (GMPs), the specific emphasis on food-safe filament led the company to update their procedures to guarantee the absence of pathogens and other contamination during the manufacturing process. They have also started working with their material suppliers for this line to ensure their compliance with GMPs. The material is made from 3D printing-grade Nature Works LLC Ingeo Biopolymer.

Among the critical hazards analyzed and brought under control in the food safety focus are factors including:

-

Raw material suppliers following GMPs

-

Food contact-approved raw materials, color pigments, and additives

-

Following GMP during manufacturing, including batch number traceability

-

Post-production microbiological analysis and cleanliness verification

-

Designated warehouse storage to reduce risk of cross-contamination

-

Providing customers with a declaration of conformance

Starting with PLA ensures optimal ease of use, as this is among the most common filament types used on desktop 3D printers. Beginners and professionals alike are fond of PLA for its non-toxic, low-odor qualities; TRUE FS PLA does not require any special print settings, high temperatures, enclosures, or any other advanced configurations. It prints with standard PLA settings (e.g., Nozzle: 190-230°C, Bed: 0-60°C).

Of course, certain considerations must be made in the print process to ensure food safety; while material leaving the Filaments.ca warehouse is food-safe, the printing conditions must maintain appropriate standards. Cleanliness of the 3D printer itself, composition of components like the extruder (Filaments.ca recommends a stainless steel nozzle), and awareness of inter-layer spacing that could potentially harbor contaminants without proper cleaning/sanitizing must be taken into consideration.

![]()

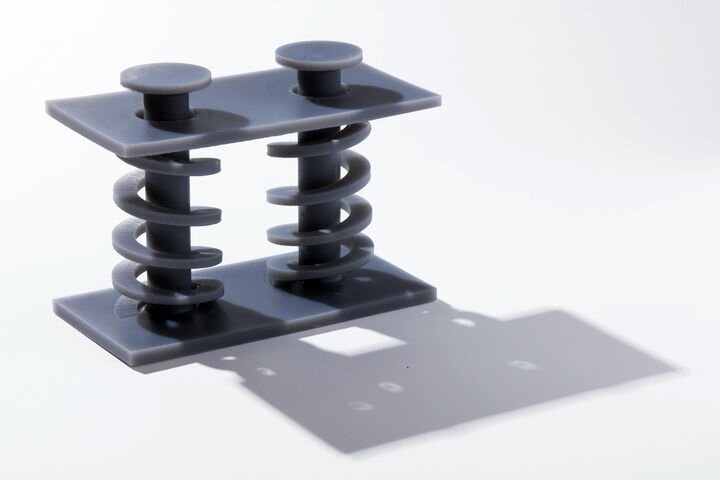

TRUE FS PLA can be annealed as well, allowing for improved heat deflection. Annealing can increase this temperature from 55-60°C to 80-90°C, allowing for parts to be washed in a dishwasher without deforming. Filaments.ca recommends using a professional lab oven, preheated to 176-266°F (80-130°C), to avoid temperature fluctuations and achieve ultimate results through the process; annealing takes 10-20 minutes in the oven.

TRUE FS PLA is available now for pre-order, with food- and skin-contact approved PETG to follow around November.

Shipping will begin October 1 for TRUE Food Safe PLA, available in 18 color choices including Water Natural, Black Licorice, Eggshell White, Berry Blue, Blue Raz, Watermelon Red, Sea Teal, Pineapple Yellow, Silver Platter, Eggplant Purple, Strawberry Red, Tangerine Orange, Pink Dragonfruit, Chocolate Brown, Charcoal Grey, Green Apple, Lacinato Green, and Mulberry Purple.

A 1kg spool of 1.75mm or 2.85mm filament is CA$44.95. Each spool is designed to be informative, allowing users to easily see net weight, total length (in meters), and the weight of the empty spool to making it easy to calculate remaining filament on partially used spools.

You can learn more about TRUE FS PLA here.

An inventive designer has developed a method for producing 3D paper objects using recycled paper and 3D printed molds.