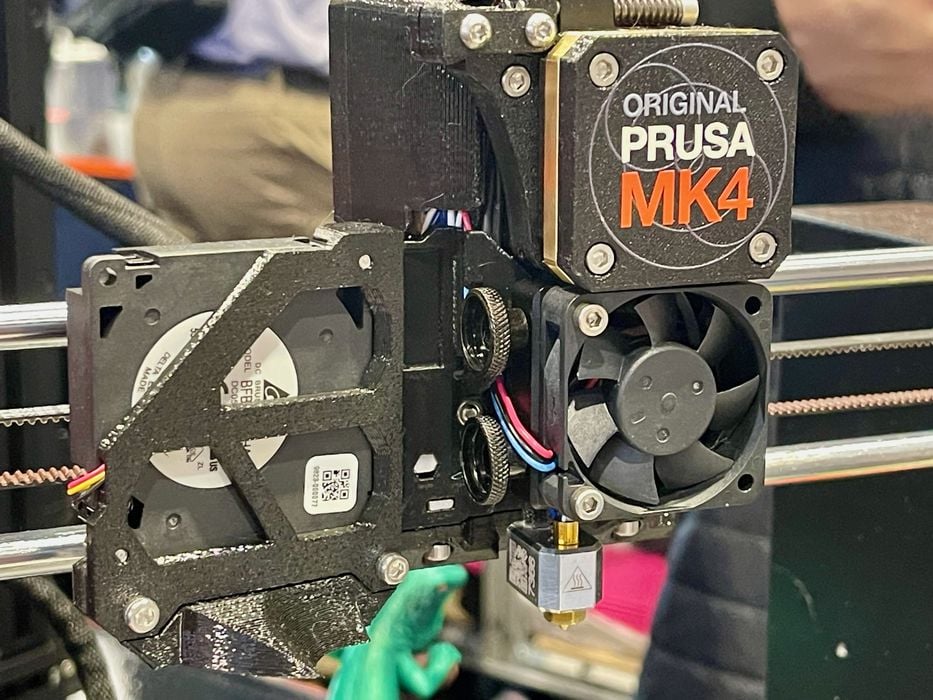

Prusa Research has released a major update to its 3D printer firmware, version 6.0.0.

The new firmware is directed to the company’s MINI, MK3.5, MK3.9 and MK4 devices, with a pending release for the larger XL device that’s still under test. This firmware is not for prior equipment, namely the MK2.x devices, which are getting pretty old now. It turns out that most of the features enabled by 6.0.0 are not really implementable on older equipment due to the lack of sensors, etc.

What’s in 6.0.0? It turns out there are quite a number of very interesting features and capabilities.

Perhaps the most practical feature is what’s called “Cancel Object”. The problem being solved is the very common circumstance where a plate of parts is printing, and one of the parts didn’t adhere properly. Normally, you’d cancel the entire job and start over — after washing the print plate, of course.

With Cancel Object you can now pause the print and indicate which failed object should be skipped. The print resumes and continues printing the remaining parts, but ignores the cancelled object.

This prevents air printing of the bad part, which inevitably leads to a complete mess as strings of filament get strewn across the print plate. Now, that can’t happen — if the operator is watching and triggers Cancel Object.

Another surprising feature is a touchscreen! It turns out that the MK4 and XL machines actually have a touchscreen that’s not enabled — until 6.0.0 is loaded. Prusa Research said that both the touchscreen and control wheel can be used, and that either could be best for specific operations. That’s quite a feat — upgrading a machine to a touchscreen via software.

The company has also introduced a form of noise reduction by calibrating motor vibrations. This is something we’ve seen in Bambu Lab equipment, and now Prusa Research has an equivalent. Prusa Research describes the “Phase Stepping” feature on the XL model as having “much quieter operation”. They also say that on some equipment it may even slightly increase print quality by reducing vibrations.

Prusa Research also re-introduced “stealth mode”, which is a single command to tune down various printer activities that reduce audible noise. This makes the device as quiet as possible, but at the cost of a slight extra premium in job time. For printers running overnight or in offices, this might be quite a useful feature.

Version 6.0.0 also makes use of the Loadcell sensor in the Nextruder assembly. The new firmware can detect stuck filaments, at least in the extruder.

Another feature I found quite interesting is that the firmware can now walk the operator through the entire process of cold-pulling. This process is used to dislodge debris stuck in the nozzle, and is commonly done — by those who know how to do it. Others simply think “there’s a jam” and give up. Now the machine itself can take you through the fix process directly.

Version 6.0.0 looks to be a very good update for Prusa equipment operators — or at least for the most recent Prusa machines, anyway.

Via Prusa Research