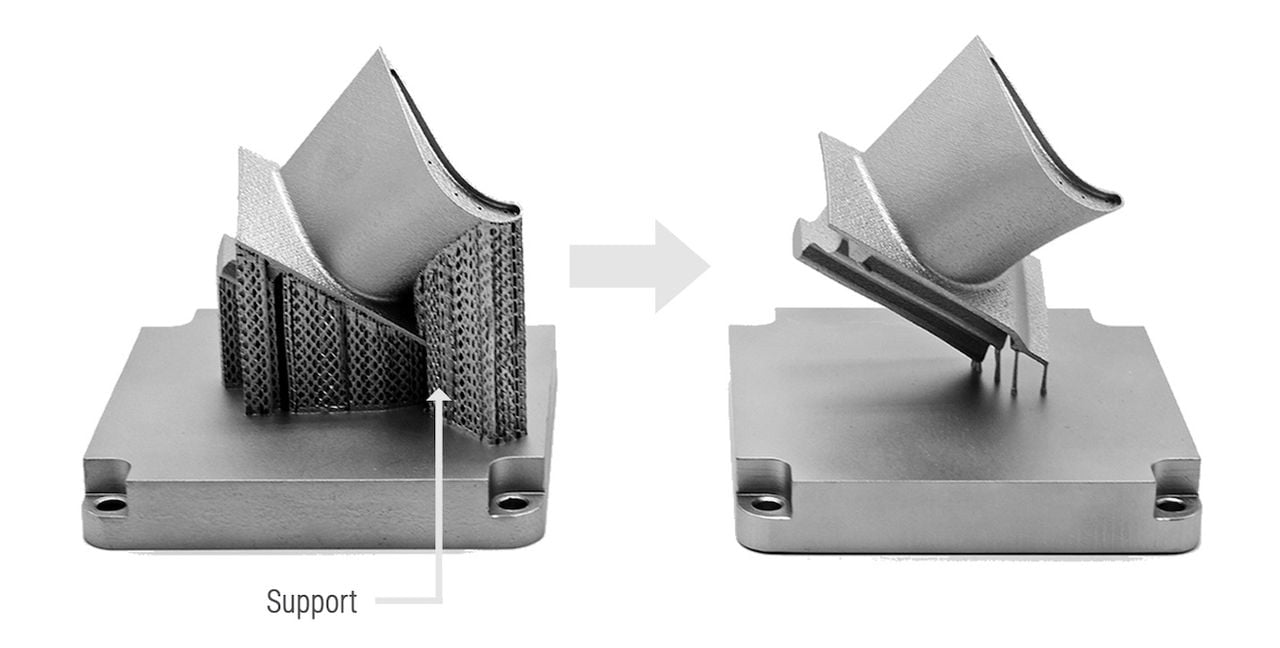

Farsoon introduced an almost unreal method of printing support structures for metal 3D prints.

They call it “SRS” for “Support Reduction System”. How much is reduced? Just take a look a the image at top — almost all of the support structures are eliminated! Farsoon explains:

“The company has successfully developed the revolutionary SRS Technology – Support Reduction System, which enables significantly fewer supports compared to the standard metal PBF process; it enables fabrication of inverted conical structures and horizontal circular holes with no support.”

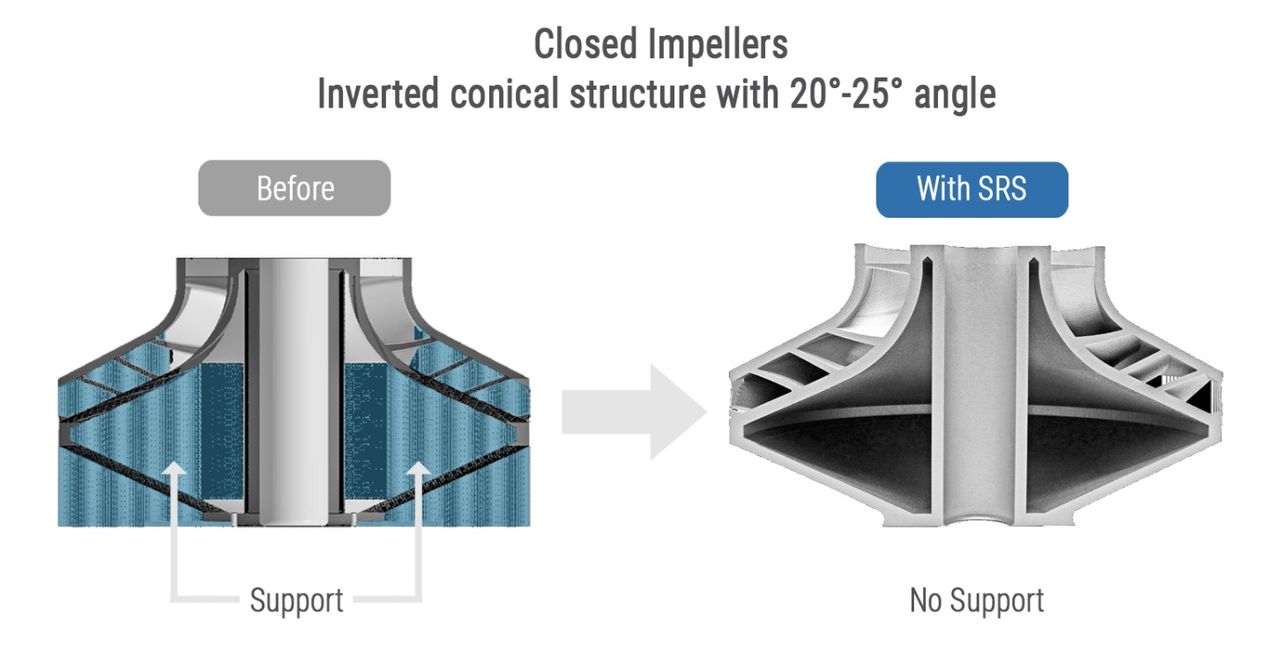

How does this work, and does it work on all geometries? Apparently there are some restrictions, as Farsoon explains:

“The SRS innovation addresses one of the most challenging aspects of additive manufacturing—internal stress and deformation during the cooling phase of metal powder bed fusion, which can lead to part failure, especially in overhanging structures. Applicable to all Farsoon metal PBF platforms, the new SRS technology successfully forms inverted conical structures with a 20°-25° angle and support-free horizontal circular holes up to 50mm in diameter.”

SRS seems to be a combination of some tricky laser scanning strategies, with intelligent algorithms, all implemented in the company’s job preparation software.

This diagram from Farsoon demonstrates how SRS could affect printing of a part that would otherwise have a significant amount of internal support structures.

In fact, this part might not even be practical to print at all if the support structures could not be reached inside the object. In other words, SRS could enable the printing of metal parts that cannot otherwise be produced.

In the above example, Farsoon indicates that SRS enabled 33% less material used and costs decreased by 25%.

There are multiple potential advantages to SRS:

- Less material is used because there are fewer support structures

- Less effort is required to remove supports after printing

- Print times decrease, allowing more effective use of the equipment

- Ability to print otherwise impossible objects

This feature provides Farsoon and its customers with a notable advantage, and demonstrates the unending possibilities of improving existing equipment through the use of advanced software.

Via Farsoon