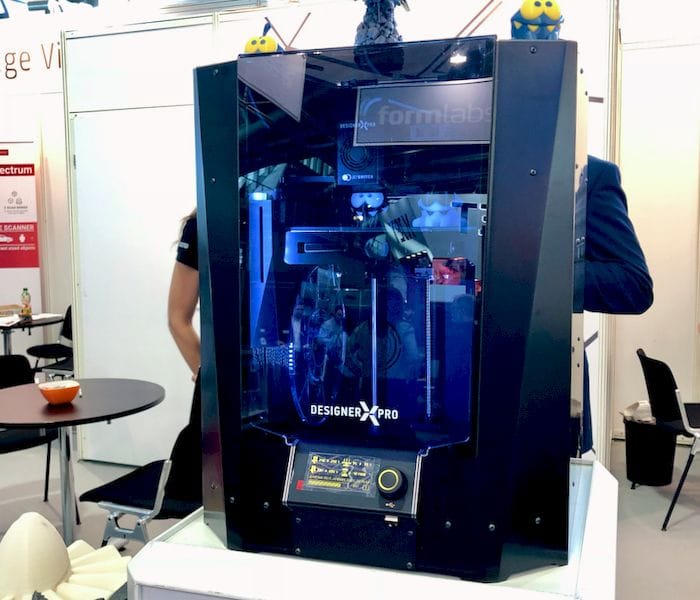

![The Picaso3D Designer X Pro [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09f7d70313.jpg)

3D printer manufacturer Picaso3D is contemplating a move into the European market.

The Russian company, in fact the first Russian 3D printer company, founded in 2011, currently has two 3D printer models. Well, maybe two and a half models. One is the Designer X, and the other is the Designer XL. There’s also another version of the Designer X called the Designer X Pro, hence my thought of two and a half models.

![Very fine details are possible with Picaso3D’s line of 3D printers [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09f7dd1ca0.jpg)

These machines offer some very intriguing features, some of which appear to be unique to Picaso3D. Here’s the most interesting features we observed:

-

Hot end maximum temperature of 410C, thus enabling the Picaso machines to 3D print exotic materials such as PEEK.

-

Print surface temperatures up to 140C, which is about as high as anything else, again enabling use of exotic materials.

-

Ability to 3D print abrasive materials like PA6-Carbon Fiber.

-

“JetSwitch”, a nozzle switching system that can execute in only five seconds, vs. approximately 40 seconds on other dual extrusion systems (on the Pro version).

-

Ability to 3D print layers as small as 0.01mm!

-

Flow control monitoring up to 3x per second, with automatic pause if issues detected.

-

Filament-out detection with automatic pause.

-

A mysterious “detachment detection” feature that apparently looks for loose bits on the build platform, whereupon it pauses the print.

-

Dual fans to ensure even heat within the build chamber.

-

Automatic print resume function after pause.

-

Print material selection AFTER slicing, done at the control panel.

-

Automatic first layer parameter adjustment depending on the material being used.

The detachment feature, also described as “surface monitoring” seems quite interesting. We’re not exactly certain how they make this work, but if it does, it should be a mandatory feature on any 3D printer.

![Samples of different print resolutions from Picaso3D, with 0.250, 0.100 and 0.010mm layer sizes [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09f7e3908a.jpg)

Picaso3D says the machines can 3D print in a large selection of engineering materials, including: ABS, PLA, HIPS, PVA, ULTRAN 630, ULTRAN 6130, ASA, ABS / PC, PET, PC, FRICTION, CAST, RELAX, ETERNAL, FLEX, RUBBER, SEALANT, PETG, AEROTEX, CERAMO, WAX, SBS, SBS PRO , PROTOTYPER SOFT, PRO-FLEX, TOTAL PRO, NYLON, PEEK and others.

![A PA-6 Carbon Fiber 3D printed part made by Picaso3D [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09f7e8c616.jpg)

The X and X Pro models sport a build volume of 200 x 200 x 210 mm, while the XL version is much larger at 360 x 360 x 610 mm.

The pricing of the machines is quite interesting: The Designer X system lists at RUB139,000, which according to our conversions is around US$2,000. That seems quite low for a machine of this capability.

Similarly, the larger Designer XL machine is said to be priced at RUB269,000 (US$3,900). Again, this seems a bit lower than it should or could be.

![Incredibly small parts can be 3D printed on Picaso3D’s equipment [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09f7edee82.jpg)

For now Picaso3D sells machines only in Russia, but they definitely have intentions of selling in the European market, as they’ve recently been busy obtaining the necessary certifications to sell within the EU. It’s quite possible they may eventually bring their products to North American and Asia as well.

We’re told that they are in fact now seeking EU-based distributors for their equipment, so if you happen to be a reseller, you might want to give them a shout.

Via Picaso3D (русский)

FELIXprinters has released a new bioprinter, the FELIX BIOprinter, which is quite a change for the long-time 3D printer manufacturer.