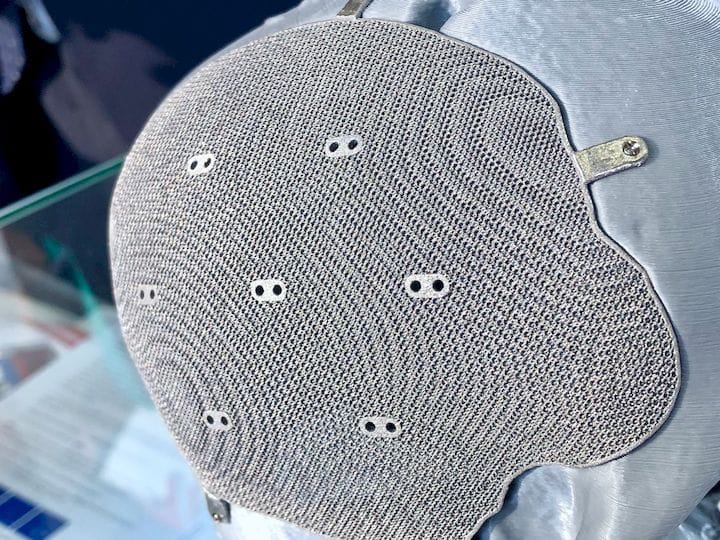

![A very detailed metal 3D print made by Winforsys [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09d4fe1cbe.jpg)

South Korea-based Winforsys offers a selection of powerful metal 3D printers.

The company has been around for quite a few years, but only recently has decided to develop 3D printers. Their heritage is interesting as it indicates considerable expertise in areas related to 3D printing and manufacturing.

They are a spinoff of a semiconductor company, and specialize in a variety of “smart factory” products. These would include things like Machine Vision systems, Particle Analyzers, Particle Counters, Predictive Analysis, Process Analysis, Automation, Remote Integration, and other management functions.

Then in 2014 they decided to begin development of a metal 3D printing system that eventually emerged in 2016, which they call the MetalSys, currently offered in four configurations.

Yes, it’s a standard powder-bed laser 3D printing system, of which we’ve seen many. It seems that many companies that have long produced CNC factory equipment have decided to add a metal 3D printer to their product line simply because they can. These systems are relatively inexpensive, but tend to not offer any new functionality nor do they recognize the tremendous operational challenges posed by metal 3D printing.

Winforsys’ options may be different, in that they seem to be applying their considerable factory monitoring expertise to the problem.

![Part of the MetalSys 3D printer’s meltpool monitoring components [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/winforsys-monitoring-1_result_img_5eb09d5046fe9.jpg)

The MetalSys machines include a sophisticated meltpool monitoring function that can increase the quality and reliability of prints. Their monitoring system is able to intercept the laser on its way to the print bed to monitor output power levels. They also include a scanner that follows the laser during printing, and can analyze meltpool emissions.

The idea is that for a given material, you would do a test run with all instrumentation deployed to perform a precise calibration. Then once you’ve got that set, you would run your production jobs through the system with good confidence of success.

![Incredibly delicate metal 3D print from Winforsys [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/winforsys-sample-2-1_result_img_5eb09d508c9b0.jpg)

The print quality is indeed excellent, as you can see in this example of an incredibly sparse print that somehow has stayed together. I don’t think I’ve seen such a delicate metal 3D print previously, and this success is likely due to their print monitoring capabilities.

![Completed metal 3D print plate from a MetalSys printer [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/winforsys-plate-1_result_img_5eb09d50d7891.jpg)

Here we see a typical print plate from a MetalSys device, filled with some bottle openers. The print came out very well, and with some finishing is quite good, as seen here:

![A polished version of the MetalSys 3D printed metal bottle opener [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/winforsys-final-1_result_img_5eb09d513ce15.jpg)

Finally, it seems that Winforsys has been working in the Asian market recently, but now wishes to expand beyond and therefore are seeking resellers for their interesting metal 3D printing equipment.

Via Winforsys

FELIXprinters has released a new bioprinter, the FELIX BIOprinter, which is quite a change for the long-time 3D printer manufacturer.