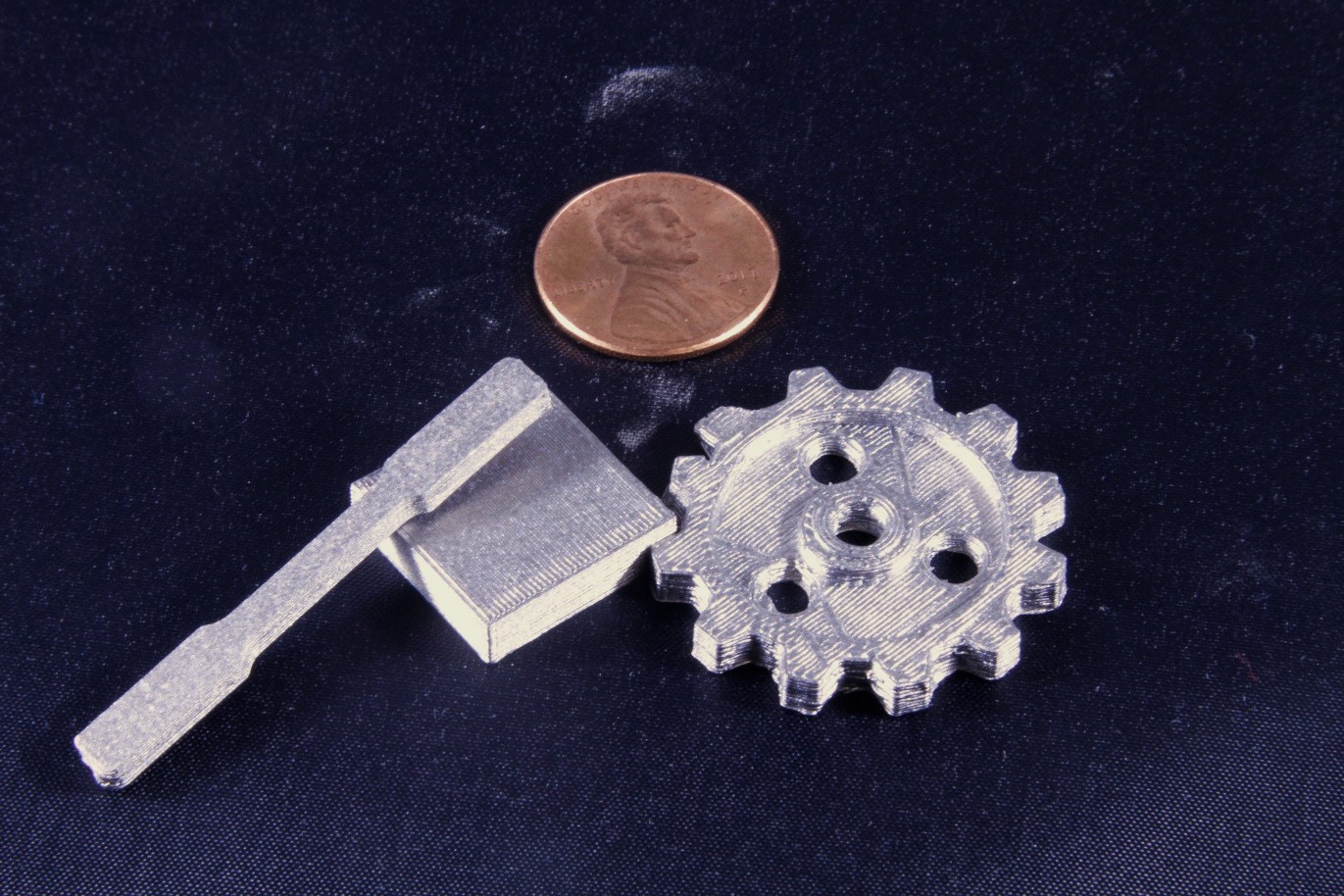

![3D printed titanium gear, dogbone, and block [Image: nScrypt]](https://fabbaloo.com/wp-content/uploads/2020/05/nscryptparts_img_5eb09a862026e.jpg)

A new metal solution promises fine-detailed 3D printing.

For nScrypt, it’s always about the details. Technologies from the Florida-based company focus on fine-featured creations with precision detailing, including work with living tissue and embedded circuits and sensors.

Now, building on work begun in 2011, nScrypt has announced a move toward a process to “provide repeatable and fine-featured metal parts to the aerospace, defense, and medical industries.”

Eight years ago, the company started working with silver.

![Printed silver NASA logo with 0.5 mm wall thickness from 2011 [Image: nScrypt]](https://fabbaloo.com/wp-content/uploads/2020/05/nscyrptnasa_img_5eb09a86b3f23.jpg)

From that foundation, nScrypt has developed a new proprietary process for 3D printing dense, detailed titanium parts.

“Our customers want to be able to 3D print metal parts in the same machine that mills them, without tool changes, and to do it without a powder bed, which is our Factory in a Tool,” said nScrypt CEO Dr. Ken Church. “These titanium parts prove that concept.”

We don’t have much detail yet on the process, but it currently works with Ti6Al4V and “can be easily expanded to other metals, including stainless steels, Inconel, and copper.” Early results of the 3D printing method showed “exceptional densities of titanium coupons, with strengths in line with wrought titanium.”

While details are quite fine from the process, it can also be used with the Factory in a Tool systems’ milling heads for finishing or polishing down to tolerances of two microns.

New developments in metal 3D printing often have to choose a focus. Some solutions, such as the supersonic SPEE3D process that can use common materials to quickly 3D print large objects, target commodity markets like mining equipment that require low costs and lots of parts. Others, like the precision system from Digital Metal, focus on highly detailed tiny parts.

nScrypt is clearly leaning toward the latter, leveraging its high-precision Micro-Dispensing technology.

Strong, fine parts are just the type of metal 3D printing results that the targeted industries — aerospace, defense, and medical — require. The introduction of this new process from an already trusted name is promising indeed for users in those areas.

Via nScrypt

Aerosint and Aconity have proven out their work in multi-metal powder deposition 3D printing.