![A Prusa i3 clone, with “Bear” upgrade [Source: Eric Au]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0972975017.jpg)

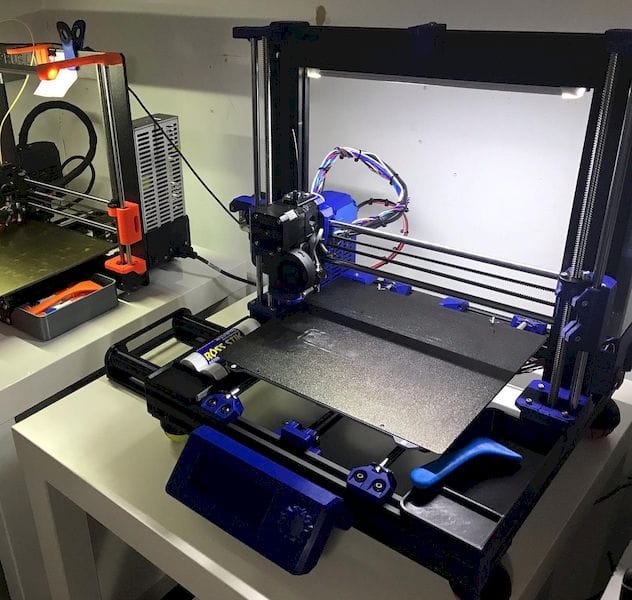

Fabbaloo friend and maker Eric Au reports on his use of a Prusa clone 3D printer.

Prusa Research is one of the leading providers of desktop 3D printers today, producing many thousands of devices each month, with well over 100,000 devices in the field today. We happen to operate several at our workshop, too. They are very good machines that produce high-quality prints at low cost.

That’s the secret to their success, but there are some potential competitors coming. Prusa Research is an open source company, and the publish the specifications and part files for their devices, such as the Original Prusa i3 MK2.

This allows others to “clone” the device and produce very similar machines, although they may have some different components. Au, who operates a small farm of 3D printers, including a true Original Prusa i3, decided to try one of these clones.

![Some of Au’s 3D printers [Source: Eric Au]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09729e1c3f.jpg)

It was not only an i3 clone, but also included a Bear-like upgrade. (The “Bear Upgrade” is a replacement frame that is far more rigid.) Au says:

“I build a bear and it prints even better than my stock Prusa i3. It’s even a Chinese kit that was CA$550 (US$407) to my door in about 4 days of ordering.”

![Parts required to be 3D printed to build the clone Prusa [Source: Eric Au]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0972a2da16.jpg)

That is quite a bit less expensive than the real Prusa kit + Bear upgrade. But does it work? Au explains:

“ZLATA [Au’s traditional codename for this build project] is alive and printing like a champ. She’s made from an AliExpress clone kit and honestly, does better work than her actual, genuine brother.

Cloned everything, even down to the Einsy board. I have it up on foam ball feet and it seriously is so quiet, I never have to enter Stealth mode.”

Au seems to be quite happy with his Prusa clone, but others may have a different opinion on this option. One commenter on the product’s AliExpress page says( via Google Translate):

“This kit is not for the inexperienced; there are no instructions and the parts are pretty much just messed up. It’s a bear frame, but they have drilled holes instead of including the brackets recommended by the people behind the bear upgrade. That dramatically increases the chances that something will not be going, but in my case it seems fine, so far. Not with the plates does the height of the printer reduce anything and make the feet fit a little differently, but not seriously. There are some wires missing (jumpers needed to power supply) and the heat break has PTFE in it, not all metal, but neither of which are a big deal. I still solder a few of wires back to the power panic, they broke off really easily. So far I’m still building it but for the price it’s a pretty decent bargain. I wish she used the original bear kit. Note there are no plastic parts – they’ll have to print * everything * that takes quite some time.”

It seems the jury is out on this one. Some may be successful with clones as they have the skills to overcome challenges such as those mentioned above. For others, however, the best choice might be a real Prusa device.

For Prusa Research, I recall the scenario many years ago when MakerBot found significant competition from Asian manufacturers using their open source plans to build clone machines at half the price. This greatly disturbed MakerBot’s then-recent big investors, who essentially forced the company to refrain from open source and close their designs forever. That did not go over well with their existing clientele.

Will the same thing happen to Prusa Research? I think not, because as far as I know, Prusa Research does not have significant investors who would force the issue on the company.

Via Eric Au and Metrograde Goods

FELIXprinters has released a new bioprinter, the FELIX BIOprinter, which is quite a change for the long-time 3D printer manufacturer.