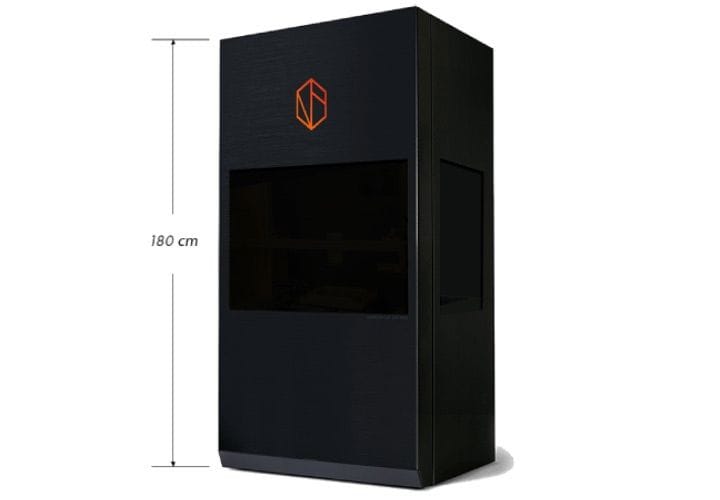

![A micro-manufacturing 3D printer [Source: Nanofabrica]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb093d361c33.jpg)

I’m reading a press release from Israel-based Nanofabrica, where they say they have achieved “viable” mass micro-manufacturing capability for small objects.

The mysterious company seems to have launched in 2016, and they intend to market a sophisticated 3D printer designed to produce small objects with extremely high resolution. Currently it appears they are in beta testing, so we don’t know much about their device — not even its name!

This is what we do know about their technology:

-

Uses photopolymer resin, currently supporting ABS-like, Polypropylene-like, Flexible, Alumina-based, and Zirconia.

-

Uses a DLP projector as a light engine, but very tightly focused down to a tiny 50 x 50 mm area, making for extremely small pixels.

-

XY resolution is a literally microscopic 1.9 microns, or 0.0019mm.

-

Layer thickness is 0.002mm, and their technology can 3D print up to 1mm per hour. That’s pretty slow as 3D printers go, but remember we’re printing very small objects here.

-

The printer is quite heavy at 450kg. This is definitely not a desktop unit, as it’s 1.8m tall.

In Nanofabrica’s latest press release, they say:

”This ground-breaking technology now provides a viable mass manufacturing alternative to traditional manufacturing processes such as micro molding, and its characteristics open up the opportunity for significant innovation in product design and development.

It is time for companies involved in the manufacture of micro parts and components or larger parts with micron tolerances to re-assess the possibilities that exist as an additive manufacturing technology enters the micro manufacturing arena.”

What I take this to mean is that the total cost of running 3D prints on their equipment is comparable to or better than the cost of traditional micro-manufacturing, which I suspect is done using high-precision CNC milling or moulding systems.

Nanofabrica Inexpensive Manufacturing?

The same equation has been executed on larger-scale 3D printers, where the cost of “tooling up” for a product can be extensive. For small quantities it’s simply not worthwhile to do. However, 3D printing does not require tooling up, as you simply print another 3D model on the same machine, perhaps with a different material. In this way it becomes financially feasible to produce smaller quantities with 3D printers, at least up to a break even point, where traditional approaches make more sense.

It seems that Nanofabrica’s financial properties may support this style of low-volume manufacturing. However, we can’t really tell by how much because they aren’t yet saying the pricing for their machine or materials. And I’m not particularly familiar with the price for traditional precision CNC milling or moulding at micro-scales for comparison.

Micro-Manufacturing Future

It’s also possible that Nanofabrica’s system could allow the production of products with complex geometries that could not ever be produced by traditional approaches. In that case, the financial equation is quite different entirely.

Micro-manufacturing is likely to be a strong growth area in the future, as there has been a constant shrinking of device sizing over many years. This trend is expected to continue into the future, suggesting the Nanofabrica is in a very good position.

Via Nanofabrica

FELIXprinters has released a new bioprinter, the FELIX BIOprinter, which is quite a change for the long-time 3D printer manufacturer.