![The 2020 Jeep Wagoneer [Source: Motor1 ]](https://fabbaloo.com/wp-content/uploads/2020/05/Jeep2_img_5eb092037fa58.png)

Charles Goulding and Peter Favata of R&D Tax Savers discuss 3D printing opportunities regarding Jeep.

Fiat Chrysler Looks for Growth with Jeep

Jeep — the car that was born out of the need for a tough vehicle the U.S. army could use in World War II — has become one of the best selling cars in America. Fiat Chrysler is looking to expand on Jeep’s leading market share in the U.S. and have greater reach in South American, European, and Chinese markets. Below is a graph showing the growth of Jeep sales in recent years:

![[Source: Wall Street Journal – August 4, 2019 ]](https://fabbaloo.com/wp-content/uploads/2020/05/Jeep1_img_5eb09203dd11a.png)

In order to drive this growth, Jeep plans on releasing larger sport utility vehicles, revitalizing the Chinese market, and introducing hybrid plug-in versions of their models in North America and Europe, where emissions regulations have been a problem for them in the past. Jeep is already generating a third of the company’s sales; notable for a car company consisted of 8 other well-known brands. As part of this innovation, Fiat Chrysler is building a $1.6 billion assembly plant in Detroit in order to begin production of new Jeep models for the U.S. and globally next year.

3D Printing Jeep Parts

With Fiat Chrysler’s emphasis on Jeep, there is an opportunity to produce 3D printed parts for all Jeep models especially the Wrangler. The Jeep Wrangler is one of the most customizable cars on the market today as you can see below:

![[Source: Motoroso ]](https://fabbaloo.com/wp-content/uploads/2020/05/Jeep3_img_5eb0920455f15.png)

With a car that is encouraged to remove the doors and roofs, one of the most appealing aspects of this vehicle is the ability to customize it, and 3D printing allows people to take that even further.

3D Printed Interior Jeep Parts

When customizing some of the interior parts, owners are 3D printing custom door handles, glove box plates, and gear shifters with unique designs. There are already websites where you can send in your design and print whatever you desire. Below are some examples of customized Jeep parts:

![[Source: jk3dparts.com ]](https://fabbaloo.com/wp-content/uploads/2020/05/Jeep4_img_5eb09204ca166.png)

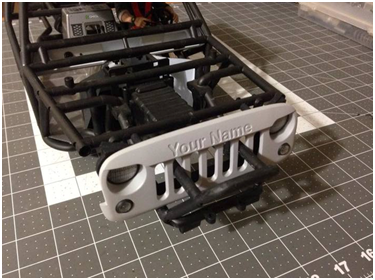

3D Printed Exterior Jeep Parts

For exterior parts, you can get the same level of customization. Many owners are printing front grills, taillight covers, and step up bars just to name a few. These parts have the same level of durability as the stock parts since Jeeps already come with many plastic exterior parts to begin with. Some of these parts can be viewed below:

[Source: shapeways.com] [Source: pinshape.com]

3D printing creates an advantage when it comes to older Jeeps where parts are no longer being produced there can always be more printed to maintain the vehicle.

Companies who engage in 3D printing of Jeep parts would be eligible for an R&D tax credit which is briefly described below.

The Research & Development Tax Credit

Enacted in 1981, the now permanent Federal Research and Development (R&D) Tax Credit allows a credit that typically ranges from 4%-7% of eligible spending for new and improved products and processes. Qualified research must meet the following four criteria:

-

Must be technological in nature

-

Must be a component of the taxpayer’s business

-

Must represent R&D in the experimental sense and generally includes all such costs related to the development or improvement of a product or process

-

Must eliminate uncertainty through a process of experimentation that considers one or more alternatives

Eligible costs include US employee wages, cost of supplies consumed in the R&D process, cost of pre-production testing, US contract research expenses, and certain costs associated with developing a patent.

On December 18, 2015, President Obama signed the PATH Act, making the R&D Tax Credit permanent. Beginning in 2016, the R&D credit can be used to offset Alternative Minimum tax for companies with revenue below $50MM and, startup businesses can obtain up to $250,000 per year in payroll tax cash rebates.

Conclusion

With Fiat Chrysler hoping to expand Jeep in the European, Chinese, and South American markets the need for parts is going to increase, and with Jeep already being the #1 selling SUV in Brazil, this expansion could be sooner rather than later.

Charles Goulding and Preeti Sulibhavi consider how two prominent automotive firms, Ferrari and Ford, are using 3D printing.