Charles R. Goulding and Peter Favata take a look at the use of 3D printing for pump prototyping, manufacture, and replacement inventory.

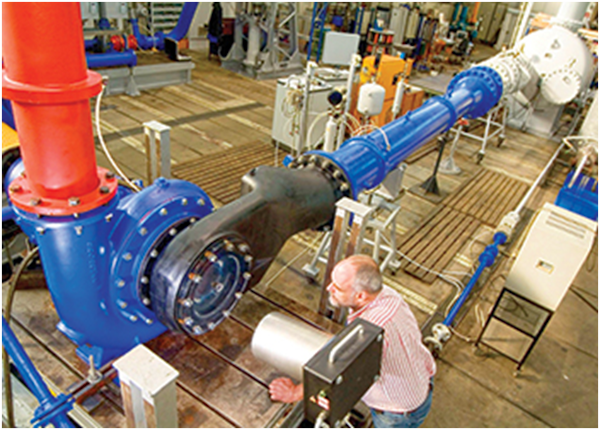

Pumps are used in a large variety of industries. In the oil industry, for example, pumps are needed for the transfer of oil. Pumps are an important tool through every stage of oil operations, upstream, midstream, and downstream. Upstream is the process of extracting the oil from the ground, midstream refers to safely transporting the oil from the extraction site, and downstream is the process of converting the oil into fuel as well as other finished products. Downstream includes marketing and distribution which includes loading and offloading at retail gas stations and home fuel oil delivers. Different types of pumps are used at every step of the way. Pumps are also used in everyday household items such as refrigerators and air conditioning systems.

Uses for 3D Printing

Utilizing additive manufacturing in the production of pumps has many different benefits at different stages of the manufacturing process. Fabbaloo recently published another article in October of 2020 talking about how the world’s largest pump manufacturer, Grundfos, currently utilizes 3D printing, this can be found here.

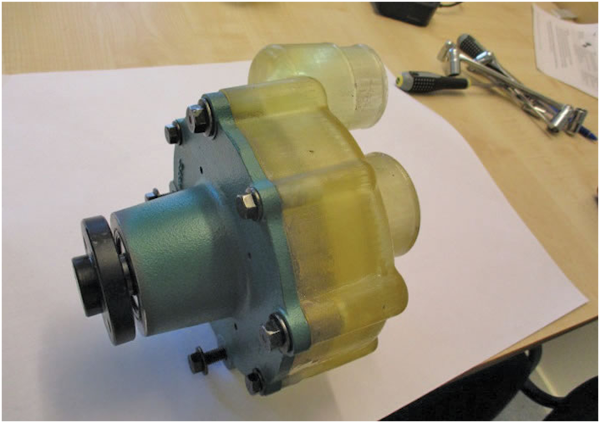

One way 3D printing is used in the production of pumps is for prototyping of parts. 3D printing allows for engineers to produce parts much quicker and on-site when designing. This also lets the designers make changes to the parts after trial and error, while also encouraging equine designs that would not be possible with traditional manufacturing methods.

Another use for 3D printing when manufacturing pumps is for pumps that are no longer in production.

Some older equipment cannot adapt to new pumps that are being produced, which leads to costly and time-consuming repairs or searching for a pump that is no longer circulating. With 3D printing, you can take a 3D scan of the older pump with which you can produce parts for repairs or an entirely new pump if needed.

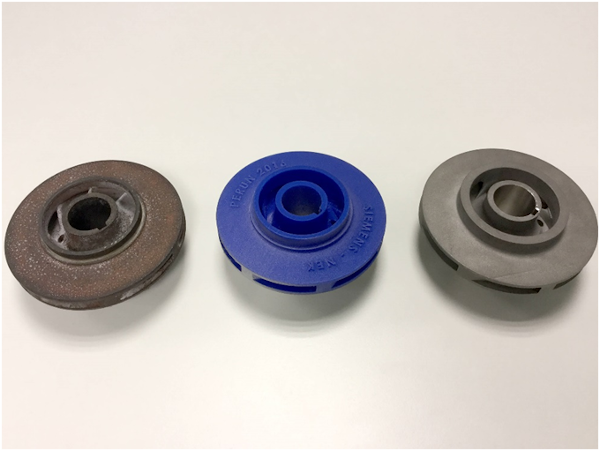

Inventory Parts

3D printing can also help with manufacturing parts for repair and inventory. Parts on pumps are expensive to manufacture, store, and replace. 3D printing cuts down the need to store replacement parts via the concept of digital inventory. 3D scans can be made of replacement parts and stored in a CAD program. If a part breaks it can be printed on-site and repaired, eliminating the need to physically store spare parts. Below is an image of a 3D printed pump replacement part.

China as a Supplier

Pre COVID-19, many major U.S. pump brands saw knockoffs of their pumps made in China. Now many U.S. pump producers and distributors do not want Chinese pumps. 3D printing enables the U.S. reshoring of pumps and their components.

The Research & Development Tax Credit

Whether it’s used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D credit-eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Enacted in 1981, the now permanent Federal Research and Development (R&D) Tax Credit allows a credit that typically ranges from 4%-7% of eligible spending for new and improved products and processes. Qualified research must meet the following four criteria:

- Must be technological in nature

- Must be a component of the taxpayer’s business

- Must represent R&D in the experimental sense and generally includes all such costs related to the development or improvement of a product or process

- Must eliminate uncertainty through a process of experimentation that considers one or more alternatives

Eligible costs include US employee wages, cost of supplies consumed in the R&D process, cost of pre-production testing, US contract research expenses, and certain costs associated with developing a patent.

On December 18, 2015, President Obama signed the PATH Act, making the R&D Tax Credit permanent. Since 2016, the R&D credit can be used to offset Alternative Minimum Tax (AMT) or companies with revenue below $50MM and, startup businesses can obtain up to $250,000 per year in cash rebates that can be applied directly to payroll taxes.

Conclusion

3D printing is an important tool in today’s pump manufacturing industry. The ability to print out replacement parts for repair that would normally take days to arrive helps to keep business moving quickly and efficiently. This would especially be helpful in the case of home heating oil delivery trucks in the winter months. When a truck breaks down in freezing temperatures you may be thanking 3D printing to keep you warm in the snow.