Healthcare professionals at Columbia University Medical Center/New York-Presbyterian Hospital using 3D printed face shields thanks to the MatterHackers Maker Response Hub.

As a French native, whose grandparents lived through World War II, I keep expecting WWIII at some point during my lifetime. I moved to the Bay Area, and kept expecting the “Big One” (read, the 9.8 earthquake everyone keeps in the back of their head while crossing the Golden Gate Bridge).

Not the most joyful thoughts, I know, but better to be ready, right?

Who knew, as we celebrated New Year’s Day 2020 barely 4 months ago, that a deadly global pandemic would be our immediate World War? And how do you get ready for such an unpredictable crisis that hits everywhere so quickly and pushes our healthcare systems to their limits?

As I watch the news and see every country, one by one, closing their borders, then ordering their population to stay confined at home, and these same people stocking up on toilet paper, food, and sometimes on ammo… well, that scares me. And I am pretty sure it scares you, too.

The production shift

Something I’ve come to realize with the COVID-19 outbreak is that no country is self-sufficient anymore, whether it is for medication, supplies such as protective masks, critical components, ventilators…. Every county relies on globalization. You can see how this can be an issue with a pandemic. Not to digress, but I believe every government, when the time to analyze the situation will come, will focus on relocalizing production of some critical components on their territory. In Western countries that are so much used to delocalizing their productions, it’s going to be a tough game.

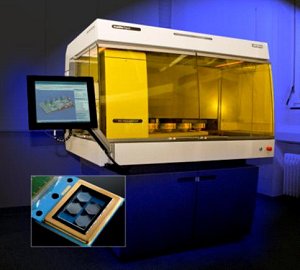

Instead of turning back in time and shutting down globalization, I believe we can be smart about what’s happening, and tackle two issues at once: For critical products and components, let’s go zero-inventory and let’s shorten the supply chain by decentralizing the production. I can totally envision a world in which a global database of certified digital copies of products, components, and spare parts are available for industries to manufacture on-demand, whenever and wherever these parts are needed thanks to digital manufacturing tools such as 3D printing. Good news is, there is a precedent, and Ivaldi Group CEO Espen Sivertsen talks about these Local Manufacturing Centers in this piece. It’s also something talked about a few months ago in my TedX Talk on supply chain.

So, will additive manufacturing have a role to play in the production shifts to come? You bet! Will we be ready? I certainly hope so!

Read the rest on Medium