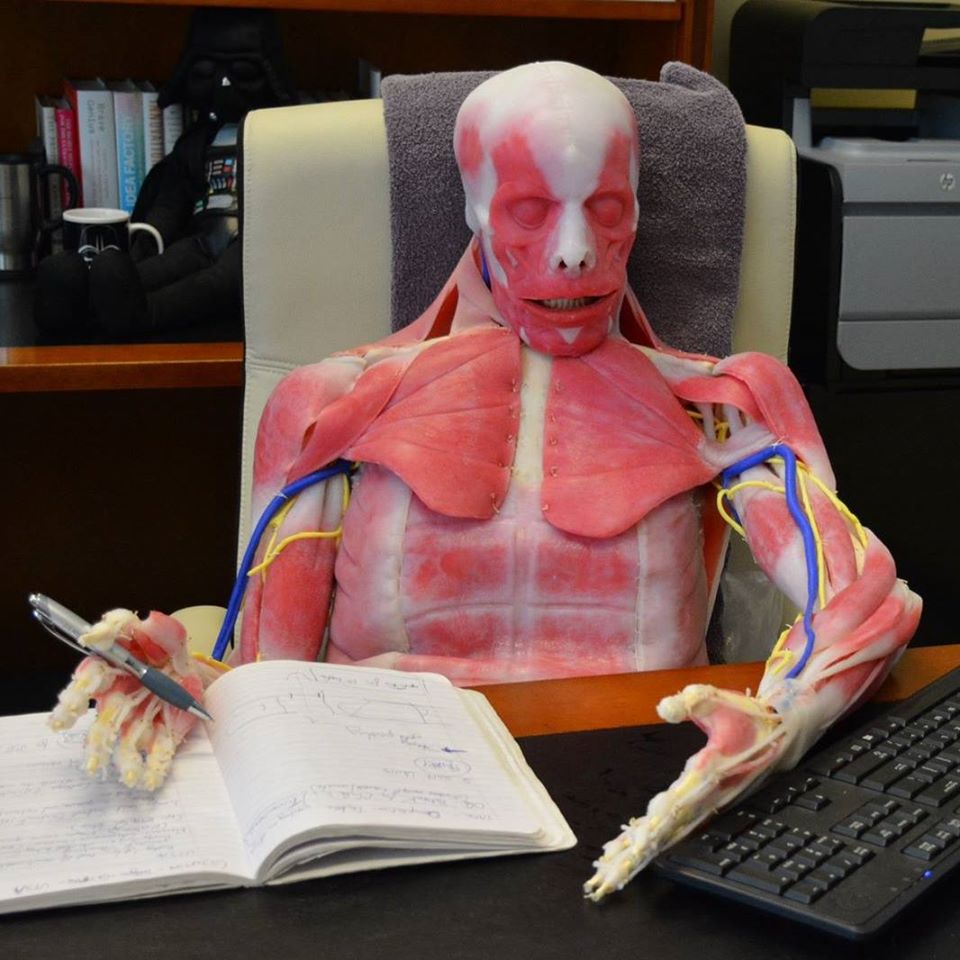

A company offering both synthetic cadavers and a new 3D printer has quite a story to tell, and what better storyteller than the CEO?

I spoke this week with Dr. Christopher Sakezles, the Founder and CEO of SynDaver, about the company’s history and initial forays into 3D printing in part one of this interview; now in part two, we look at how 2020 has introduced a new business strategy in building 3D printers.

SynDaver and LulzBot

As Sakezles explained in part one, SynDaver offered LulzBot TAZ 6 3D printers with its kits intended to introduce middle and high school students to engineering concepts through building a medical mannequin.

The company had been working directly with LulzBot on developing new approaches to including these 3D printers in the kits.

“We were talking with their senior people about putting this bundle together and selling it through them and a couple resellers. Then the communication just stopped,” Sakezles told me. “Everything that happened within the company, I had no idea; they were I suppose rightfully not telling anyone. I got a note from the person I had been dealing with that they had been let go, and the company was sold, and essentially everyone that was part of the company was let go too. I didn’t know any of this was going on.”

As we know, the autumn of 2019 was a tipping point for LulzBot. We weren’t quite so in the dark about it, as we spoke to former employees following massive LulzBot layoffs, and caught up with Aleph Objects’ founder for a chat, and followed the story through to LulzBot eventually being bought by North Dakota-based FAME 3D and spoke to the new leadership there as well.

But for Sakezles and the SynDaver team, these goings-on weren’t just a surprise, they were difficult to navigate from a business perspective.

“It kind of left us high and dry, and sent us back to square one. Had I known the company was even available or for sale, I would have wanted to buy them myself to make them part of SynDaver, but I wasn’t given that opportunity,” he told me.

SynDaver 3D Printing

While Sakezles didn’t buy the LulzBot assets himself, he did find the next best thing to keep everything running smoothly for SynDaver’s 3D printing needs.

“I found out all these people were unemployed now in Loveland, and I couldn’t believe it. There were all these glittering jewels just thrown out and left on the ground; I was flabbergasted anyone would do such a thing. The most valuable thing in a company is the people in it. The ones that know how to do anything, they’re your store of knowledge and skill,” he continued. “As soon as I found that out, I went out there and set up a meeting. I decided to continue with what I had been doing, just in a different way — building the printer myself.”

Sakezles hired “a handful, about ten people, most from the company that was disbanded, and a couple who aren’t” to form SynDaver West.

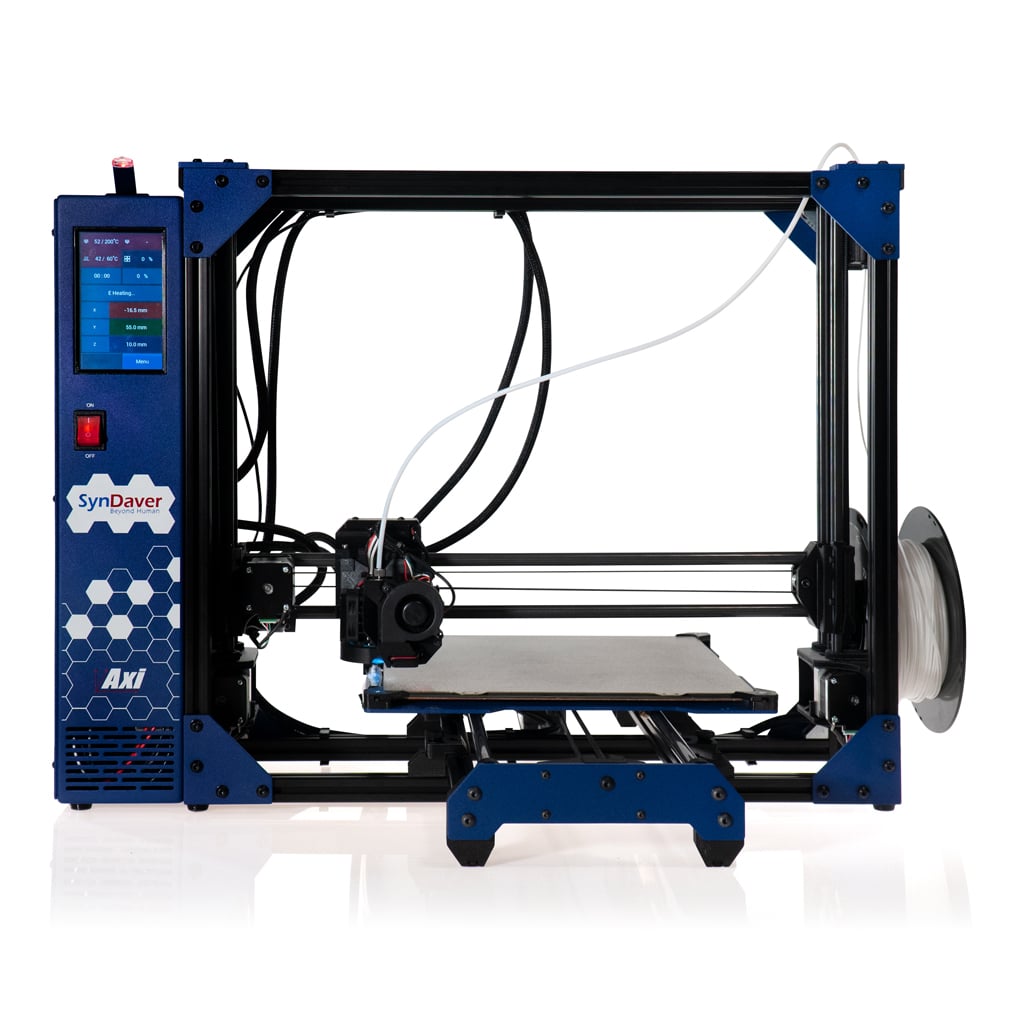

This is the entity we heard about last month, with early reports from the local Loveland Reporter-Herald highlighting a new 3D printer. The Axi 3D printer debuted at the beginning of June.

“The Axi is really something we made just to include with our engineering kits for the most part,” Sakezles explained of making the machine. “We are definitely going out and putting them on the open market too, because why not, but that wasn’t the original intent. The original intent was to build a printer to go out with our kits and build specialized technologies.”

That initial need met, though, SynDaver also finds itself with a new offering in its portfolio. So, I asked, what comes after building this new segment?

“What we’re going to be doing is basically growing that group, adding in outside talent, different technologies. It’s not going to stay what it is now. They’re doing what they’re doing now as an opening act. That’s just a beginning for us,” Sakezles told me.

At this time, he wasn’t able to get into the specifics of what is to come from this beginning. There will be “printing-related things, manufacturing things related to what SynDaver’s known for, tissue,” he hinted.

Especially appealing for SynDaver in regards to more 3D printing is the automation technology involved. They can use this “in a lot of different ways,” as Sakezles sees “applications in other consumer and industrial products.”

SynDaver and FAME 3D

What is hopefully a footnote to this story, but still a question asked, is how things stand now that the Axi is on the market, effectively competing with LulzBot 3D printers.

We’ve seen something of the FAME 3D response, as the company has pulled out from reseller agreements with distributors who are now also offering the Axi.

So I asked Sakezles how that decision sits with him.

“They’re going to do what they’re going to do; it’s not what I would have done,” he said. “I certainly wish them no harm. I don’t know why anybody would do that though, that’s counterproductive. We live in a society, in an economy where people compete with one another, companies compete with other companies. You win by having a superior product, not by product censorship. Get the best products out there, get customers a great warranty, and in the end the best product’s going to win: that’s the way it should be. Aside from you telling me, I don’t have any first-hand knowledge of that…I don’t know what to say beyond I don’t understand it and it’s not what I would have done. I think it was unnecessary, and I’m hoping that clearer heads will prevail and they’ll make up with their distributors.”

SynDaver Diversified

Moving back to SynDaver itself, Sakezles’ description of it as “a fairly diversified company” seems quite fair.

SynDaver primarily serves the educational space, he explained, though it also participates extensively in the medical device and pharmaceutical industries and does work for the military.

“3D printing as a product line is new for us, and that’s kind of a tangent that’s taken us into consumer products a little more as a company, and that will continue kind of as an aside,” he told me. “Our primary business will still be business-to-business and business-to-government, rather than business-to-consumer.”

A diversified portfolio that’s continuing to diversify represents additional opportunity for the company, in the end, and Sakezles sees this as an interesting ongoing pursuit.

“We still will continue to make consumer-focused types of printers. That’s something that’s going to, for us, continue for the long haul. This isn’t something I did on a lark,” he said. “I pick different kinds of products and technologies because there’s cross-pollination between the new things and the old things. It’s not just to diversify, but that’s one thing that allows companies like ours to flourish in times like these. We have multiple revenue legs to stand on with multiple types of customers. That’s something we’ll continue to do as a company.”

Next For SynDaver

On top of presenting an interesting business opportunity, Sakezles sees 3D printing as one of the ways the company is maintaining business operations in a difficult, pandemic-time economic climate. But beyond security of operation, this new leg to stand on is indeed proving to be important in the developing long-term strategic vision.

“3D printing as a technology will continue to become more and more important as it switches from a niche, fun thing to do to one that begins to replace labor to a certain extent in some applications. We’re going to continue to invest in the technology for that reason and other reasons,” Sakezles said.

Per the company’s Facebook page, there’s even more to look forward to, as well. It seems that SynDaver will begin offering filament that “will most likely not come online until the end of July.” At that time, the post continues:

“We will be offering PLA, PLA/PHA, ABS, PETG, CoPolyester and TPU – primarily in 1.75 but we may also make some 3mm.”

SynDaver will not use proprietary materials (“I find that practice to be very distasteful and would never do such a thing”) — “but we will be giving discounts on SynDaver filaments to Axi owners,” the Facebook post notes.

The Facebook page is enlightening as well, as the SynDaver team underscores the quality aspect of their system:

“[W]e aren’t aiming to compete with Chinese kits. Our product is very high quality as evidenced by the 3 year warranty. It’s made and supported in the USA, comes with discounts on SynDaver filament and it is available with SynDaver financing. In addition, we will take the machine back (under 3 years of age) if it is traded on a nextgen SynDaver product. Our customer only experiences a small amount of annual depreciation so that $3250 will still be worth $2350 after three years of use.

As we closed out our conversation, I asked Sakezles for any final impressions he wanted to share. In keeping with much of the tone of our chat, he turned again to the value he places on his team.

“I would say the staff we have at the 3D printing operation are super high-quality folks, I’m very proud of them, I’m impressed with them. Not just their knowledge and skill, but their good nature and their dedication. They’re good folks, they do good work. I’m proud of what they‘ve accomplished in a very short period of time,” he said.

And the new 3D printer?

“I think anyone who uses an Axi will be pleased with it. It’s not perfect, like nothing’s perfect, but it’s a good machine,” Sakezles told me. “Any additional products we come out with will continue to get better and better.”

Per the SynDaver Facebook page, again, it sounds like these additional products will up the focus on the industrial aspect:

“Just one version [is available] at the moment but follow on products will be more complex and expensive. Axi is likely to be the least expensive printer we ever produce.”

Via SynDaver