Robot Factory announced the “Steel Roller Kit”, which converts a normal desktop 3D printer into a continuously operating device.

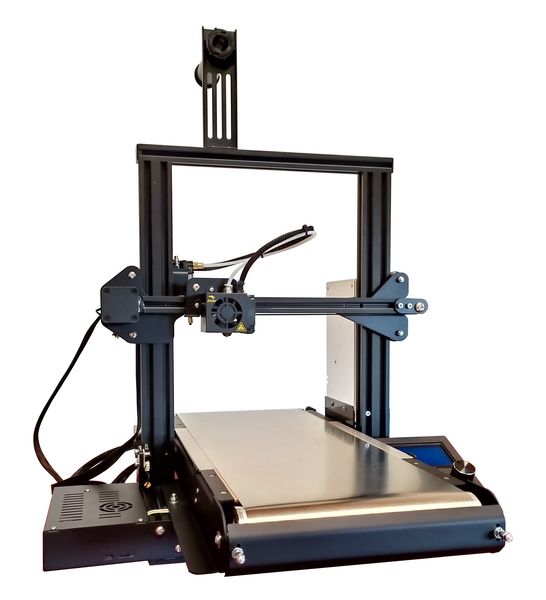

SilverBelt 3D Printer

Venice-based Robot Factory has been working with continuous 3D printing for a while, having announced their own belt 3D printer last fall at Formnext. The SilverBelt device uses a steel conveyor belt on which thermoplastic is extruded at a 45-degree angle. As the belt moves during printing, it allows for near-continuous 3D printing. One could, if a sufficient supply of filament is provided, print an endless stream of small objects, or, if desired, an object longer than the 3D printer itself.

Robot Factory calls this technology “FDM-45”, which makes sense. However, they’d better check with Stratasys, who have long trademarked “FDM”. Perhaps it should be called “FFF-45”?

Robot Factory still sells the Silver Belt, but apparently saw an opportunity to provide similar functionality to operators of other 3D printers. Their new “Steel Roller Kit” is an upgrade that can be applied to many commonly used desktop 3D printers to convert them into continuous 3D printers.

Robot Factory Steel Roller Kit

Essentially the kit replaces the print bed entirely, while the remainder of the motion system on the original 3D printer is re-used, but in a different way. The kit is composed of:

- Programmer for the boot loader with instructions

- Marlin Firmware 1.1.9.1 (or latesst update)

- Cable for the SD slot

- GCODE for belt advancement (and ejection of the printed piece) at the end of a print job

- Assembly Instructions

- Simplify3D profile

- Firmware

They say the assembly process is relatively straightforward, and involves replacing the Y-axis mechanism with the new roller and reprogramming the motherboard and firmware. 3D printer models apparently compatible with this upgrade include a number of models with i3-style motion systems:

- Artillery Genius

- Side Winder X1

- Creality CR-10, Ender series, CR-6 SE

- Anycubic Chiron

- Anycubic I3-Mega

- Anycubic Mega0

- Longher LK4 Pro

- Lulzbot series

- Sovol SV02

- Wanhao D12 230

- Prusa I3 MK3S

It’s likely there are additional compatible devices that are not listed.

This may appear to be a serious upgrade, and thus may be beyond the capability of some operators. To assure buyers of the ease of the upgrade process, Robot Factory provides a downloadable PDF of the detailed assembly steps.

I took a look at this PDF and found it be a non-trivial upgrade to be sure, but the steps seemed straightforward. I suspect many readers will be able to get through them.

Pricing of the Steel Roller Kit is not specified. Instead you’ll have to contact Robot Factory through their enquiry form. If I had to guess, the pricing could be more than some of the 3D printers on the list above.

But what is the value of a continuously operating 3D printer? To some, it could be priceless.

Via Robot Factory