Charles R. Goulding and Adam Friedman consider 3D printing software advances focused in Seattle.

An August 10, 2020, Wall Street Journal VC Daily newsletter confirms investors’ opinion that Seattle is a highly attractive city for software startup companies. With this desirability tag, Seattle, Washington has become a world leader in software development in the 21st century. Much of this is credited with the preeminence of Microsoft Corporation and rising technology companies such as Amazon. Seattle boasts tens of thousands of professional programmers, many of whom utilize the C#/. NET framework of Microsoft and use cloud computing services such as Amazon Web Services.

3D printing has also become a strong Seattle-centered technology. 3D printing’s emergence in software-heavy Seattle bodes well for the merging of new software development with 3D printing. The following examples will explain:

3D Printing in Seattle

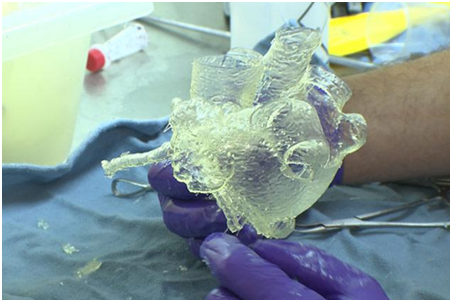

The University of Washington at Seattle has been the state’s premier university undergoing projects involving 3D printing. In August 2019, the Veteran Affairs Puget Sound Health Care System and the University of Washington School of Medicine announced a two-year partnership to advance 3D printing in the medical arenas. Other departments have incrementally worked on 3D printing projects at the University of Washington at Seattle. These products range from a 3D printed cell phone charger to 3D printed prosthetic devices to 3D printed gloves that speak and sound out sign language. Many of these projects have been catapulted by software engineering of Seattle-based developers and custom APIs written by Seattle-based companies.

Companies in Seattle, ranging from industrial heating to aerospace, have incorporated 3D printing in their technology and products. Tukwila-based RedDOT Corporation has invested in 3D printing for HVAC systems for trucks and heavy equipment. In the aerospace sector, companies have been manufacturing different spacecraft parts with 3D printers. Planetary Resources used 3D printed casting patterns to assemble a fuel tank installed and used in its satellites for asteroid mining. Another Redmond company, Aerojet Rocketdyne, with researchers at Washington State University, will 3D print miniature research satellites. These projects are monumental as spacecraft that can use 3D printing will benefit the many projects that will “consumerize” space travel and exploration. The software used in Planetary Resources’ 3D printing was developed by 3D Systems, which has offices in Seattle.

Seattle Software and 3D Printing Convergence

Looking forward, more products being manufactured will be generated by 3D printing. 3D printing requires effective and well-practiced software that can handle the prototyping and directions for creating 3D printed products. Seattle is a robust software development market that can build and sustain the software required for 3D printers and for new and highly demanded 3D printed materials.

Greater demand for 3D printed materials and a skilled software engineering market in Seattle will converge where more area engineers will shift focus on writing 3D printer software. On the other end of the convergence will be more 3D printed manufacturing taking place in Seattle as it has become a city to best create the software to build profitable 3D printers and/or materials.

There are a few startups that have intersected with software and 3D printing. Dyndrite, located by the Pike Place Market of Seattle, has been highly successful in merging software and 3D printing. Their novel GPU kernel (operating system) processes the software for most, if not all, 3D printers.

The Research and Development Tax Credit

Whether it’s used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Enacted in 1981, the now permanent Federal Research and Development (R&D) Tax Credit allows a credit that typically ranges from 4%-7% of eligible spending for new and improved products and processes. Qualified research must meet the following four criteria:

- Must be technological in nature

- Must be a component of the taxpayer’s business

- Must represent R&D in the experimental sense and generally includes all such costs related to the development or improvement of a product or process

- Must eliminate uncertainty through a process of experimentation that considers one or more alternatives

Eligible costs include US employee wages, cost of supplies consumed in the R&D process, cost of pre-production testing, US contract research expenses, and certain costs associated with developing a patent.

On December 18, 2015, President Obama signed the PATH Act, making the R&D Tax Credit permanent. Beginning in 2016, the R&D credit has been used to offset Alternative Minimum Tax (AMT) for companies with revenue below $50MM and, startup businesses can obtain up to $250,000 per year in payroll tax cash rebates.

Conclusion

Seattle has become a software center in the United States. This expertise in software will enable Seattle to continue great work on new 3D printed products and technologies.