Charles R. Goulding and Preeti Sulibhavi examine how a drainage company could make use of 3D printing technology.

Advanced Drainage Systems is to starting construction on a US$65M, 110,000-square-foot office, warehouse and laboratory on 17 acres of land located on the west side of Interstate 270 in Hillard, Ohio.

“Now is the right time. This investment will allow for us to grow, get our engineers, materials and product developers in the same space (and) unlock some opportunities,” Brian King, executive vice president, product management and marketing for Advanced Drainage Systems, Inc., told ThisWeek on August 29, 2022.

The groundbreaking was in October and the new facility is expected to open in late 2023, King said.

Water management solutions is one of the most relevant topics we have today. ADS is providing unique and highly advanced solutions to solve water management problems. ADS has been utilizing 3D printing for such projects.

In 2018 ADS received an award for its Greenville, South Carolina drainage system. The award was sponsored by the Corrugated Plastic Pipe Association Division of the Plastics Pipe Institute. We have previously written about how 3D printing can play a key role in the design and development of pipes, pumps, valves, filters, and other items meant to handle the current water infrastructure crisis.

ADS provides the components and ancillary equipment for septic tanks. Septic tanks are prevalent in areas without sewer systems. Advanced septic tanks that reduce nitrate emissions are becoming more prevalent and sometimes mandated in coastal regions concerned about water pollution.

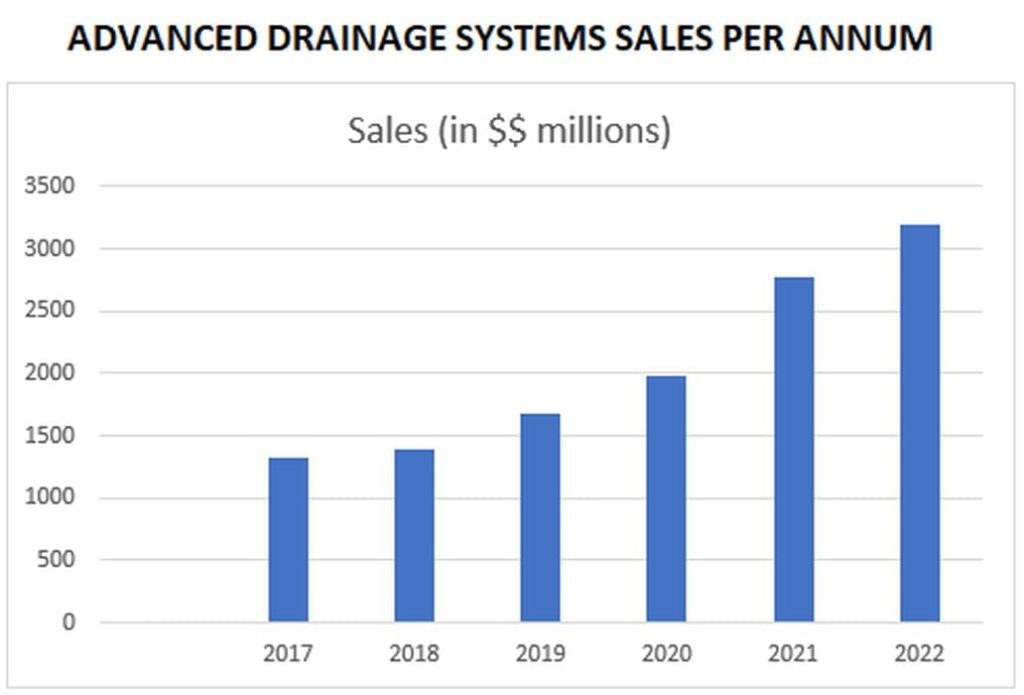

The high rate of ADS’ annual growth speaks for itself:

The 2022 announcement for its plans to build a new US$65M facility, called the Engineering and Technology Center, in Hillard, Ohio, comes on the heels of its 3D printing commitment. “The Engineering and Technology Center will be where ADS creates new and innovative products, finds better materials ¾ including with recycled plastics –– and develops the manufacturing processes that allow us to be more efficient in producing these cutting-edge stormwater solutions,” said ADS President and CEO Scott Barbour.

According to the ADS website, the ADS Engineering and Technology Center is expected to open in late 2023, expanding ADS’ engineering and technology operations and allowing the company to consolidate all of the current product development and testing operations and manufacturing engineering development into one central location. It will include:

- A product development lab focused on the full range of a product’s life cycle including:

- An area to prepare product samples for testing.

- A fabrication lab to develop prototype parts and test fixtures.

- A lab to analyze structural performance of prototypes under different conditions.

- A 3D printing lab to rapidly develop and vet concepts.

- A hydraulics lab that supports ADS’ water treatment businesses including separation, traditional filtration and low impact development filtration.

- An advanced technology lab for manufacturing and engineering prototyping.

And materials science laboratories providing:

- Extensive performance-based materials test capability.

- Analytic tools to generate structural and chemical information on investigated materials.

- Extrusion capability for development of next-generation product formulations.

The fact that ADS has identified a lab dedicated to 3D printing research and development is a substantial development for the industry.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

ADS is using 3D printing to help us live more sustainable and environmentally friendly lives and using 3D printing to make this a reality. More companies should see this as a positive development as well as an economically beneficial one and take note.