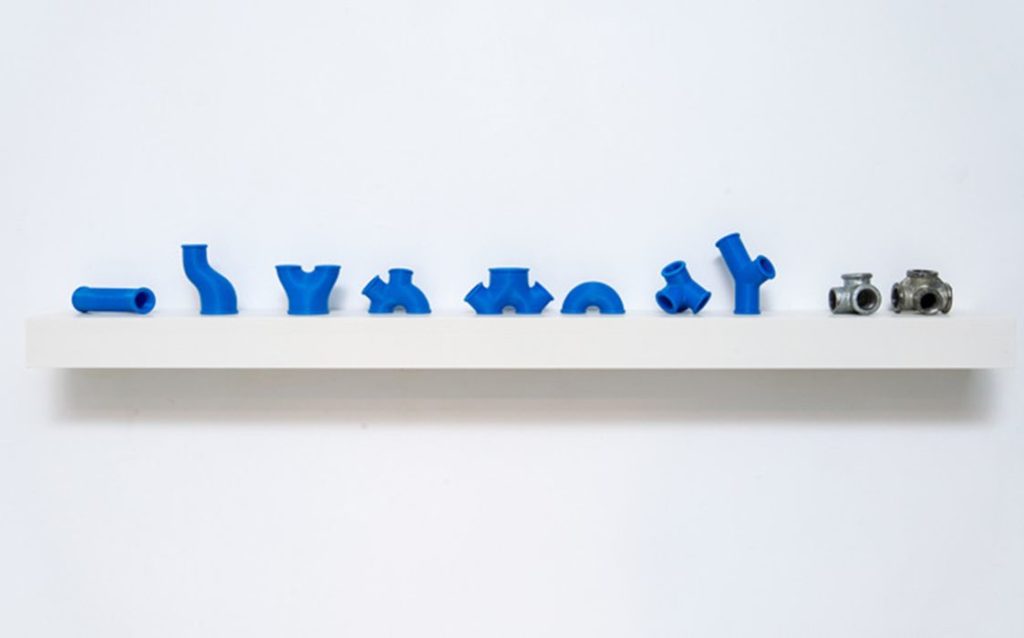

Maya Ben David: Bypass [Source: Domus]

Charles R. Goulding and Preeti Sulibhavi look at the possibilities when using 3D printing for plumbing applications.

Ever since the integration of indoor plumbing in standard homes, the industry has grown exponentially. Any home today needs indoor plumbing and with that comes many different parts and connectors. Plumbing components include piping, connectors, threaded caps, etc. There is plumbing equipment as well: sinks, toilets, baths, showers, kitchen plumbing and more. All of these items are part and parcel of modern life.

There are now more ways to 3D print plumbing parts and components than ever. Everything from valves to pumps can be 3D printed efficiently.

Copper Piping and Plumbers

Copper piping is the traditional material that is used for water supply lines, although certain plastic piping materials are gaining popularity. Drain waste pipes are usually plastic and can be 3D printed. 3D printers that use thermoplastic filaments can pproduce piping that is durable and able to be used as part of a building’s plumbing system. These pipes serve to carry waste down and away from the home and allow the sewer gases to be pushed out through the roof. The common material that is frequently used for plumbing is acrylonitrile butadiene styrene (ABS). This petroleum-based material is a common thermoplastic polymer and comes in various mixes. A strong material, it is affordable and easy to shape which is perfect when inserted into a 3D printer. During 3D printing the filament slowly flows from the print head and shrinks slightly as it cools down.

Usually, water pipes have a standardized structure to them. The fittings are 90, 45 and T shape angles and the pipes are joined together in these settings only. However, what if these pipes could be printed using additive manufacturing? By using additive manufacturing, water pipe fittings can be designed with bends that are innovative and a custom alternate solution to the typical joint bends. Using a 3D printer allows designers and construction workers to to more easily work with pipe configurations in the way they actually need. They are able to make and bend them in any fashion they choose as long as they meet the needed requirements.

3D Printed Parts

3D printed product designs are flexible and can fix any mechanical needs. Use a 3D printer to make pipe connectors. If the piping is running at a 45-90 degree angle and the connectors don’t work efficiently, then 3D print your own custom connector. These connectors hold the pipes in place and allow for rapid and simple fixes. Maya Ben David, a designer from Israel has come up with 3D printing of various piping and water systems. The Bypass project is where 3D printing is used to produce the fittings. Bypass presents a range of pragmatic solutions in a systematic way, by creating a range of possibilities for pipe fittings that are also compatible with existing standards.

Printing Threaded Caps

A plumbing system is a network of pipes and fixtures in a building. Sometimes even the best-designed plumbing systems can have design problems. When a pipe gets clogged a cleanout is needed. Usually, a plumbing system has one or more cleanouts that can be regulated from the inside or outside of a house. An inside cleanout is usually done where grime gets clogged in the pipes such as at a joint or a point where two pipes are connected. Another location for grime to collect is where the stack pipe meets the underground building sewer. The cleanout points on the outside can easily be identified. There is a removable threaded cap that has a square fitting that can be opened with a wrench. This part can be 3D printed as well from a desktop printer.

The Research and Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies and startups developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

Innovative approaches using 3D printing technology are helping business component designers, engineers, designers provide improved plumbing systems for plumbing supply houses. Those companies involved with 3D printing of plumbing, pipes, fixtures and accessories may be innovating for themselves and the plumbing industry.