A 3D print company has shifted to a four-day week.

We’re all accustomed to operating in the standard five day work week, so this is a notable change.

The five day work week evolved over time, beginning as a volunteer practice in the early Industrial Revolution to create a partial “weekend”. In the early 20th century a five day formal work week emerged in certain companies in the USA, but became a de facto standard after labor action at Ford Motor Company plants in the 1920s. Thereafter the USA and multiple states legislated the five day work week concept, and there it stands today.

https://en.wikipedia.org/wiki/Workweek_and_weekend

However, today is very different from 100 years ago. Now we rely far, far less on labor and instead automation does most of the work. The complexities of modern life are vastly greater as well, leading to highly stressful working conditions. To counteract this, and leverage today’s automation and connectivity, a four day work week has been considered.

Very few companies use a four day work week, but recently there has been a pilot project taking place where a number of companies volunteered to undertake the measure.

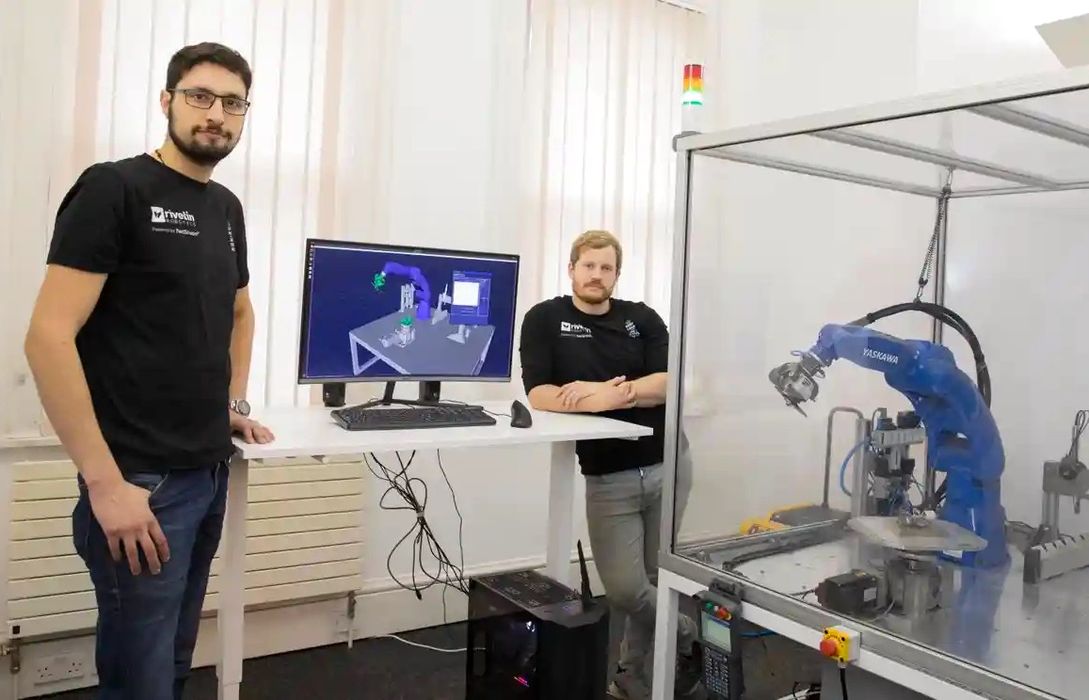

One of the pilot project companies was none other than UK’s Rivelin Robotics, who we recently spoke with at Formnext 2022.

https://www.fabbaloo.com/news/a-look-at-rivelins-impressive-metal-post-processor

The Sheffield company produces an AI-powered metal 3D print post processing device. It is able to remove support structures, smooth surfaces and more — entirely without human intervention. Normally, the process of metal print finishing occupies a significant portion of the cost chain, and requires skilled technicians. Even so, results can be inconsistent because, well, humans.

Rivelin Robotics’ system completely changes that equation to consistently produce near-perfect results for each part.

Their approach to the four day week involved taking Fridays off, while adding 90 minutes to each of the other four days. More or less, the same number of hours were being worked, but on fewer days.

While most of the company’s staff liked the new work week, there were some issues. One was interacting with other companies, which, as you might guess, continue to work five days a week. Friday contacts had to be dealt with, regardless of what Rivelin Robotics was doing internally.

Rivelin Robotics’ David Mason explained another issue:

“We had a trade show that was a big launch for one of our products and a couple of the major parts were delayed. And we just couldn’t physically start the process until they arrived. There was no way at that point in time that we could have spread that load.”

Some staff desired shorter days, but this leads to the realization that everyone has different needs and that most likely some type of flexible system would ultimately be required.

The Guardian reports:

“In total, about 2,900 employees across the UK have taken part in the pilot. Surveys of staff taken before and after found that 39% said they were less stressed, 40% were sleeping better and 54% said it was easier to balance work and home responsibilities.

The number of sick days taken during the trial fell by about two-thirds and 57% fewer staff left the firms taking part compared with the same period a year earlier.”

Apparently 92% of the participating companies opted to extend their four day work week pilots, suggesting there’s something valuable in the practice.

Those are significant results, and companies using five day work weeks should consider what this could mean for their operations.

Like most industries, 3D printing is deeply set in the five day work week. In some cases, it’s six or seven days, particularly in startup companies that struggle to reach viability.

Converting to a four day work week is a huge step for any operation, but as more companies do so, it will become easier. Management and staff will come to expect this treatment, and it’s possible legislation could eventually appear, just as it did 100 years ago.

In the long term, this is likely necessary. Automation will continue to increase, and much more rapidly as new AI tools emerge. Those AI tools, which today are mostly online in nature, will soon be connected to machinery. That will take bigger and bigger bites out of available work.

What will people do? The four day work week is a start in that direction, but eventually we may have three day weeks. Or two day weeks.

Myself, I’m hoping for zero day work weeks.

Via The Guardian

US Digital (an optical encoder manufacturer in Vancouver, WA) has been doing a 4 day work week (10 hours x 4 days) for years.

However, for industries with high capital equipment costs (think semiconductor), this isn’t going to happen. I’ve seen such companies use a 3.5 day work week: 12 hours shifts, alternating between 3 and 4 days a week. So the plant runs 24×7 with 4 shifts.